Method for preparing tellurium dioxide by using crude tellurium as raw material

A technology for tellurium dioxide and raw materials is applied in the field of preparing tellurium dioxide, which can solve problems such as human injury and environmental pollution, and achieve the effects of easy operation, reduction of environmental pollution and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

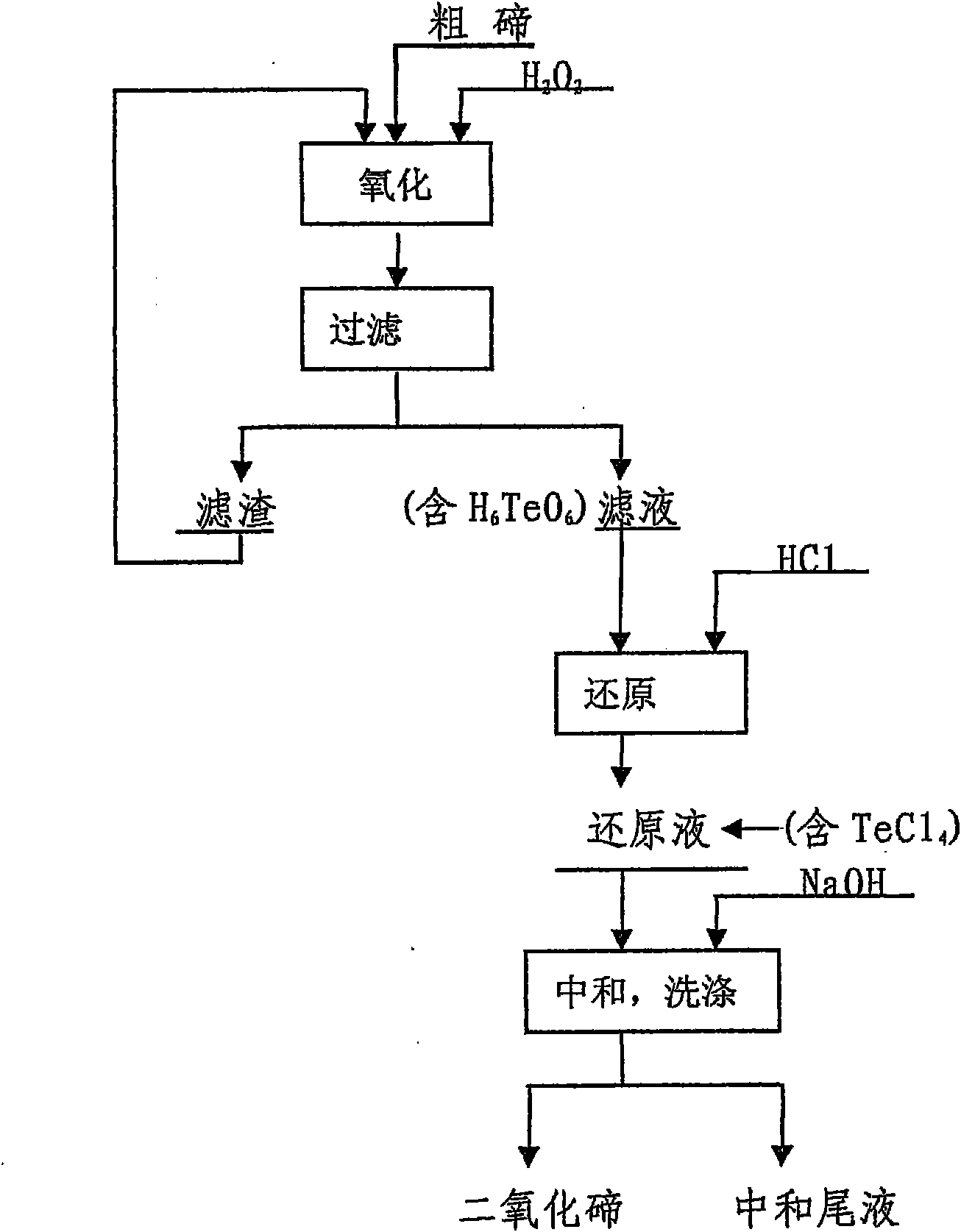

Method used

Image

Examples

Embodiment 1

[0041] Put 100 kg of crude tellurium containing 50% into a reaction kettle with a stirrer and a thermometer, add hydrogen peroxide with a concentration of 12%, add crude tellurium according to the liquid-solid ratio = 3, and grind the crude tellurium into an average particle size of ~ 74μm fine powder, tellurium content ≥ 50%, stir evenly, heat to boiling, react for 1.5h, filter, the filter residue still contains a small amount of tellurium, return to the next oxidation, the filtrate containing orthotelluric acid requires no solid suspended matter, clear and transparent;

[0042] Add hydrochloric acid with a concentration of 36% to the above-mentioned orthotelluric acid solution, the dosage is 2.5 times the weight of tellurium powder, heat to boiling, and react for 1.5h. During this process, a small amount of chlorine gas escapes, and the ventilation and protection are strengthened. TeCl 4 The yellow-green clear liquid continued to concentrate to 3 / 4 of its original volume.

...

Embodiment 2

[0046] Put 100 kg of crude tellurium containing 50% into a reaction kettle with a stirrer and a thermometer, add hydrogen peroxide with a concentration of 15%, add crude tellurium according to liquid-solid ratio = 3, and grind the crude tellurium into an average particle size of ~ 74μm fine powder, tellurium content ≥ 50%, stir evenly, heat to boiling, react for 2.5h, filter, the filter residue still contains a small amount of tellurium, return to the next oxidation, the filtrate containing orthotelluric acid requires no solid suspended matter, clear and transparent;

[0047] Add hydrochloric acid with a concentration of 36% to the above-mentioned orthotelluric acid solution, the dosage is 3 times the weight of tellurium powder, heat to boiling, and react for 3 hours. During this process, a small amount of chlorine gas escapes, and the ventilation and protection are strengthened. TeCl 4 Yellow-green clear liquid, continue to concentrate to 1 / 2 of the original volume.

[0048]...

Embodiment 3

[0051] Put 100 kg of crude tellurium containing 50% into a reaction kettle with a stirrer and a thermometer, add hydrogen peroxide with a concentration of 12%, add crude tellurium according to the liquid-solid ratio = 3, and grind the crude tellurium into an average particle size of ~ 74μm fine powder, tellurium content ≥ 50%, stir evenly, heat to boiling, react for 2 hours, filter, the filter residue still contains a small amount of tellurium, return to the next oxidation, the filtrate containing orthotelluric acid requires no solid suspended matter, clear and transparent;

[0052] Add hydrochloric acid with a concentration of 36% to the above-mentioned orthotelluric acid solution, the dosage is 2.8 times the weight of tellurium powder, heat to boiling, and react for 2 hours. During this process, a small amount of chlorine gas escapes, and the ventilation and protection are strengthened. TeCl 4 Yellow-green clear liquid, continue to concentrate to 1 / 2 of the original volume. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com