Nuclear magnetic resonance radio-frequency micro-coil and manufacturing method thereof

A technology of nuclear magnetic resonance and manufacturing method, which is applied in the direction of using nuclear magnetic resonance for analysis and magnetic resonance measurement. Uniformity of spin excitation, high manufacturing precision, and high uniformity of magnetic field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

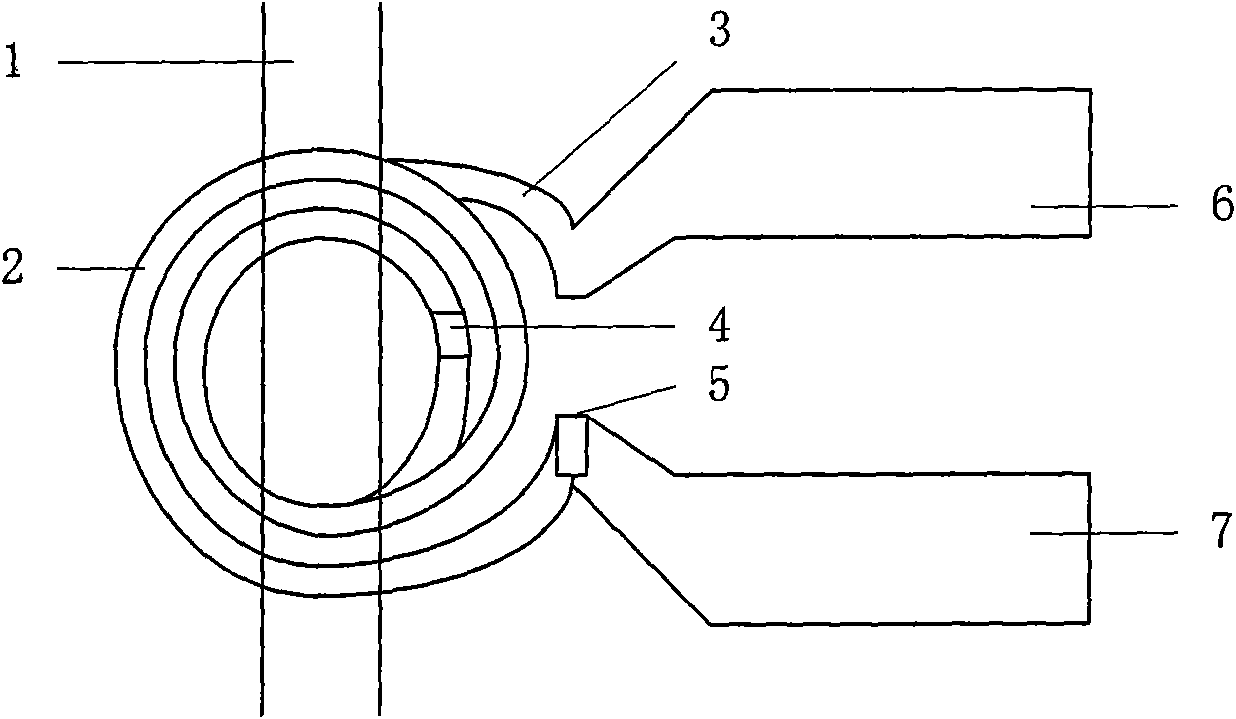

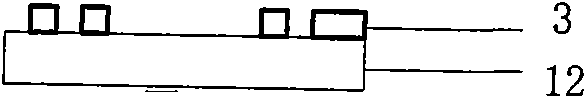

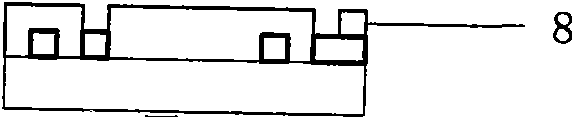

[0031] Such as figure 1 As shown, the Helmholtz-type nuclear magnetic resonance radio frequency microcoil of the present invention is composed of a top layer sub-coil 2, a bottom layer sub-coil 3, an inner via hole 4, an outer via hole 5, a first pad 6 and a second pad 7. The via hole 4 is located at the connection between the bottom layer sub-coil 3 and the top layer sub-coil 2, so as to realize the electrical connection between the bottom layer sub-coil 3 and the top layer sub-coil 2, and the outer via 5 is located between the top layer sub-coil 2 and the second pad 7 to realize the electrical connection between the top sub-coil 2 and the pad 7, that is, the first pad 6, the bottom sub-coil 3, the inner via 4, the top sub-coil 2, the outer via 5 and the second pad 7 in sequence electrical connection. The microchannel 1 containing the sample is located between the top sub-coil 2 and the bottom sub-coil 3 , and is parallel to both the top sub-coil 2 and the bottom sub-coil 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com