Swaging manufacturing method of light aluminum alloy rim

A manufacturing method and technology of aluminum alloy, applied in the field of forging, can solve the problems of high waste, high manufacturing cost, large material consumption, etc., and achieve the effects of easy production, long service life and simple mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

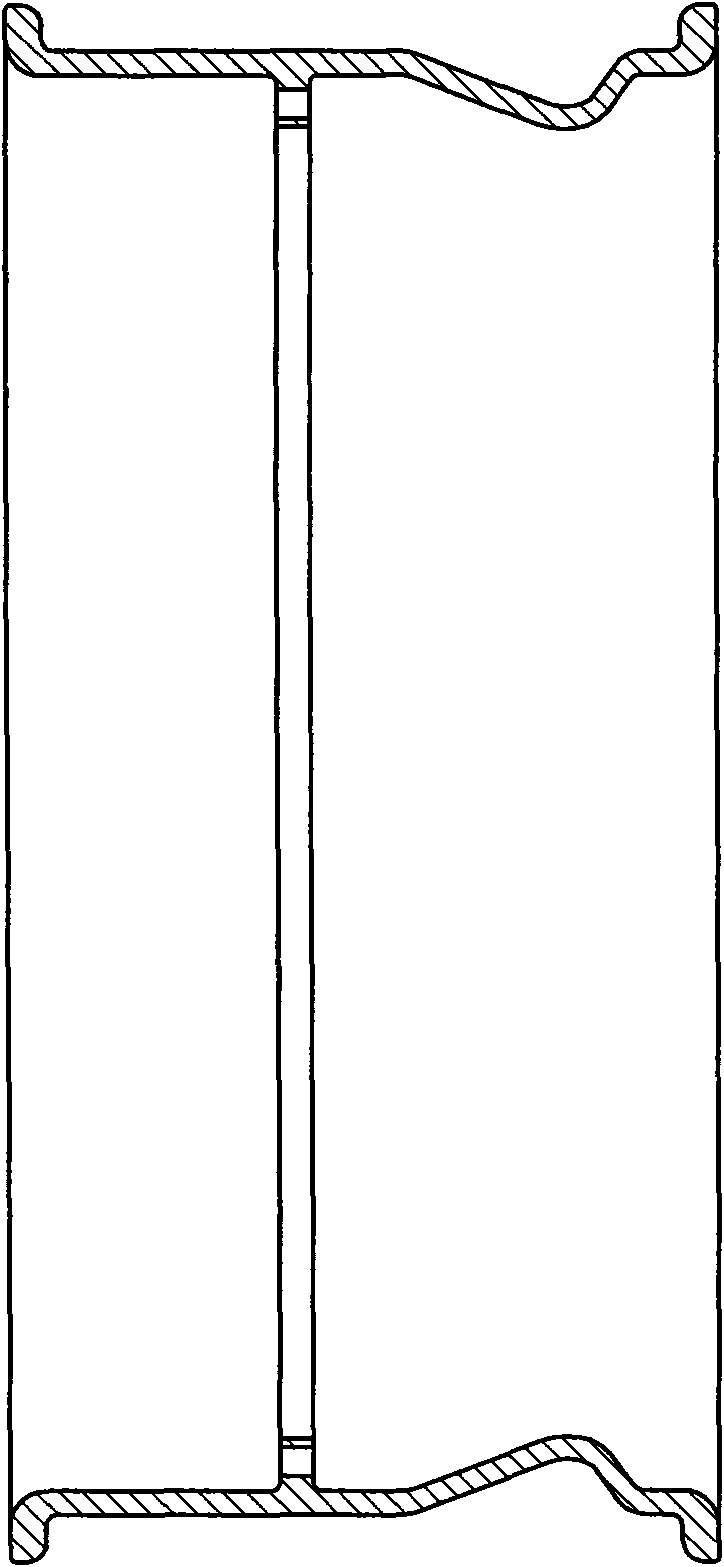

[0025] The processing steps of the forging and spinning manufacturing method of light aluminum alloy wheel rim:

[0026] 1) Blanking: select aviation-grade aluminum alloy bars with a diameter of 250 mm, saw them into sheet-shaped blanks according to the size of the rim, and pass the flaw detection test;

[0027] 2) Heating: Put the qualified billets in the chain belt furnace and heat them to 450-520°C. The heating time for the first batch is 35-40 minutes and the continuous production is 10-15 minutes;

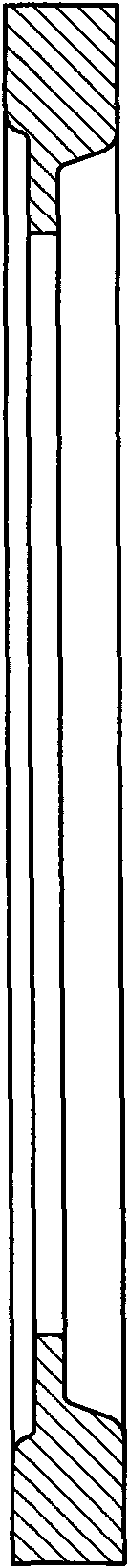

[0028] 3) Ring forging: Send the heated blank to the press for ring forging, and forge the sheet-shaped blank into an aluminum alloy blank ring, such as figure 1 shown;

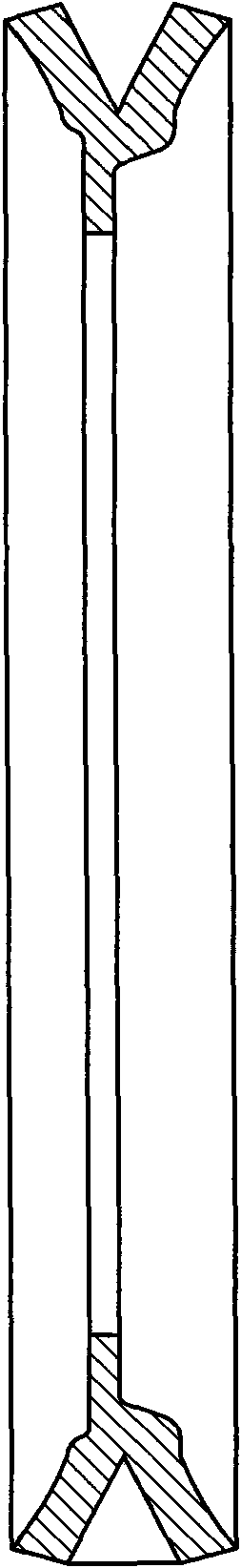

[0029] 4) Making the spinning blank: On the spinning machine, the aluminum alloy blank ring is cut radially outwards from the middle of the blank ring into two halves, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com