Method for producing low-salt fermented bean curd

A production method and a salt-cured technology are applied in the production field of low-salt fermented bean curd, which can solve the problems of prolonging the production cycle, inactivating enzymes, and understanding the superiority of desalinating fermented bean curd, and achieves the effect of reducing the amount of salt added and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

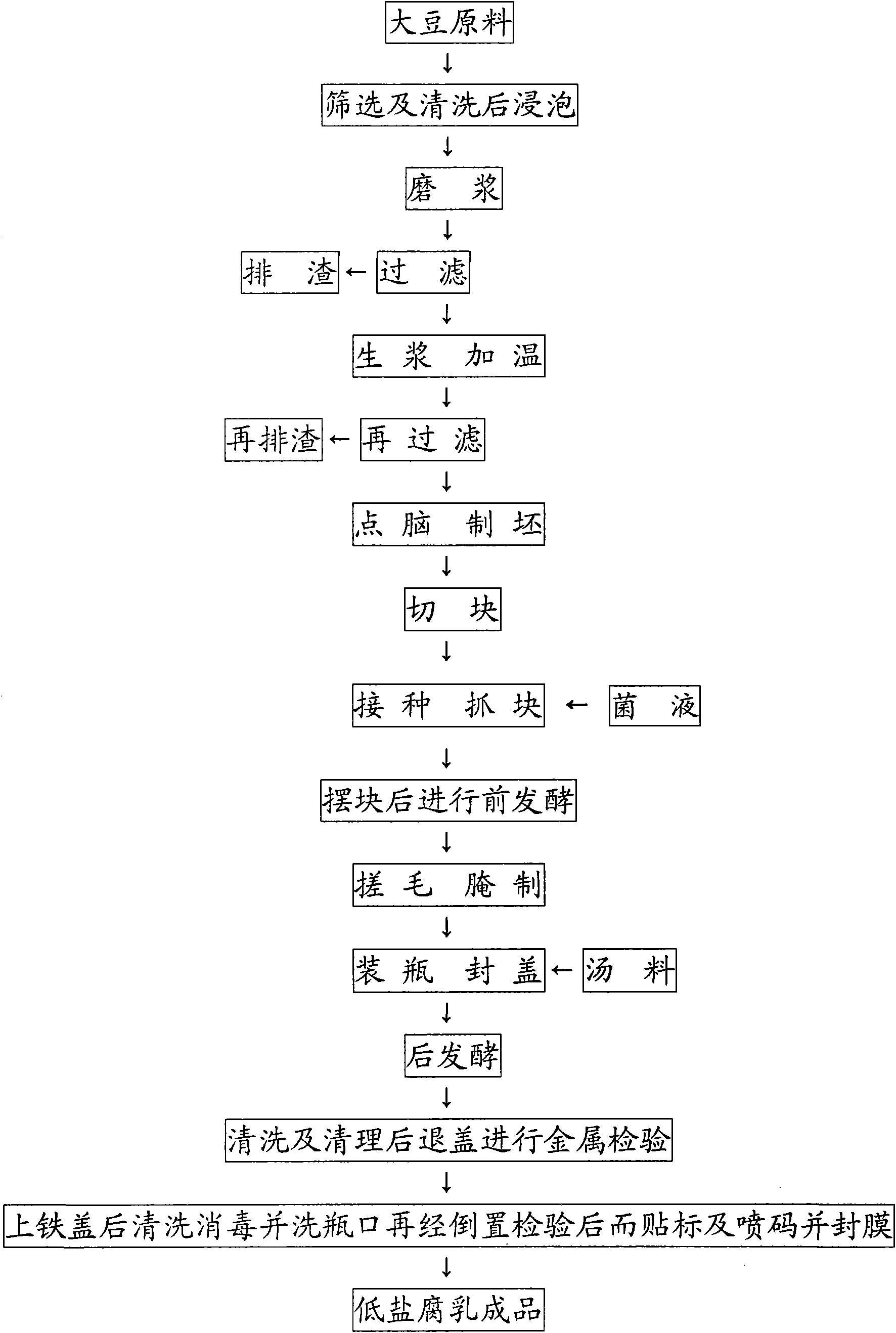

[0026] Below in conjunction with accompanying drawing of description, the production method of low-salt fermented bean curd of the present invention is described in detail, just as shown in accompanying drawing of description:

[0027] A method for producing low-salt fermented bean curd, comprising using soybeans as raw materials, screening, washing and soaking the raw materials, refining, filtering and deslagging to obtain raw pulp, heating the raw pulp, filtering the heated slurry and re- After slag discharge, do brain-making, cut into pieces, grab the pieces after inoculation with bacterial liquid, place the pieces and then carry out pre-fermentation, kneading and marinating, bottling and adding soup, then capping, post-fermentation, cleaning and cleaning, and then capping The production process of the finished fermented bean curd product obtained by carrying out metal inspection, cleaning and disinfection after putting on the iron cover, washing the bottle mouth, labeling, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com