Cylindrical continuous-casting tundish

A continuous casting tundish, barrel-shaped technology, applied in foundry equipment, casting melt containers, metal processing equipment, etc., can solve the problems of uneven distribution of molten steel composition and inclusion content, large molten steel temperature difference, etc. The effect of reducing the possibility of secondary pollution, reducing corrosion and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

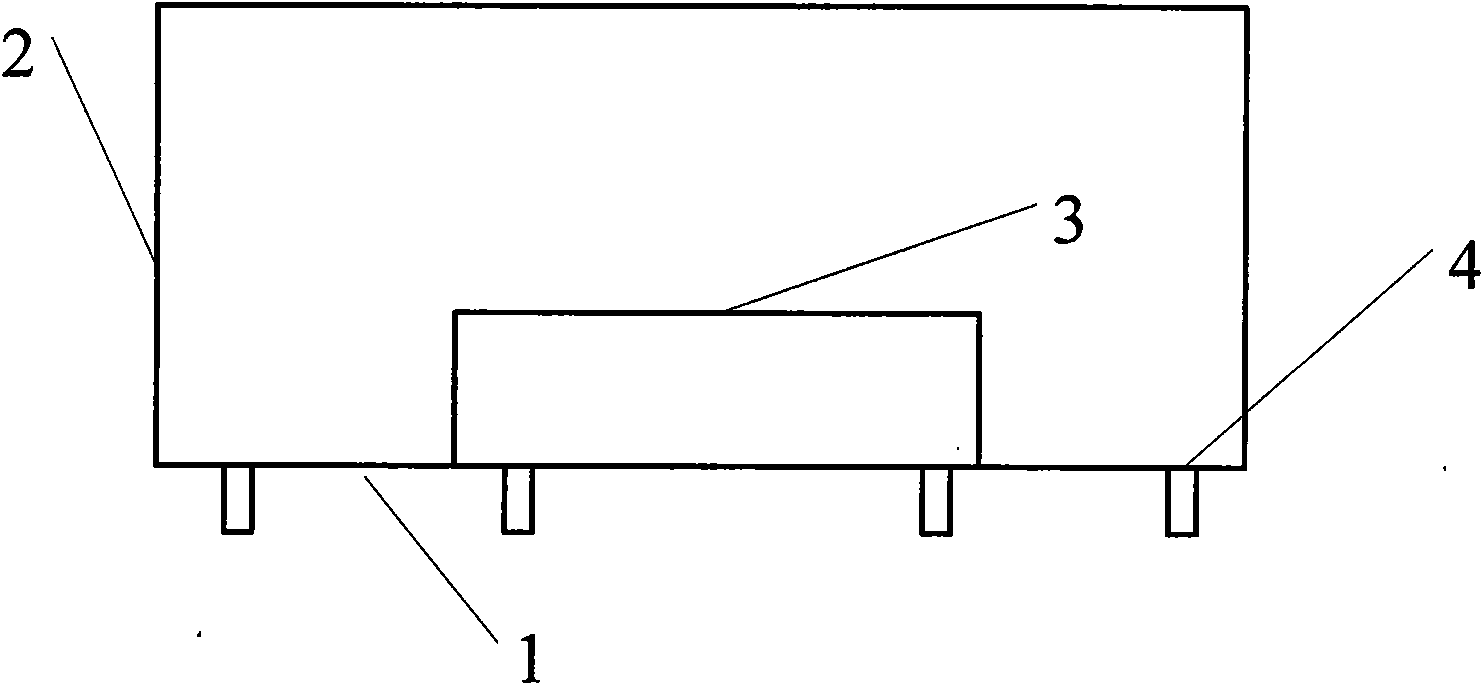

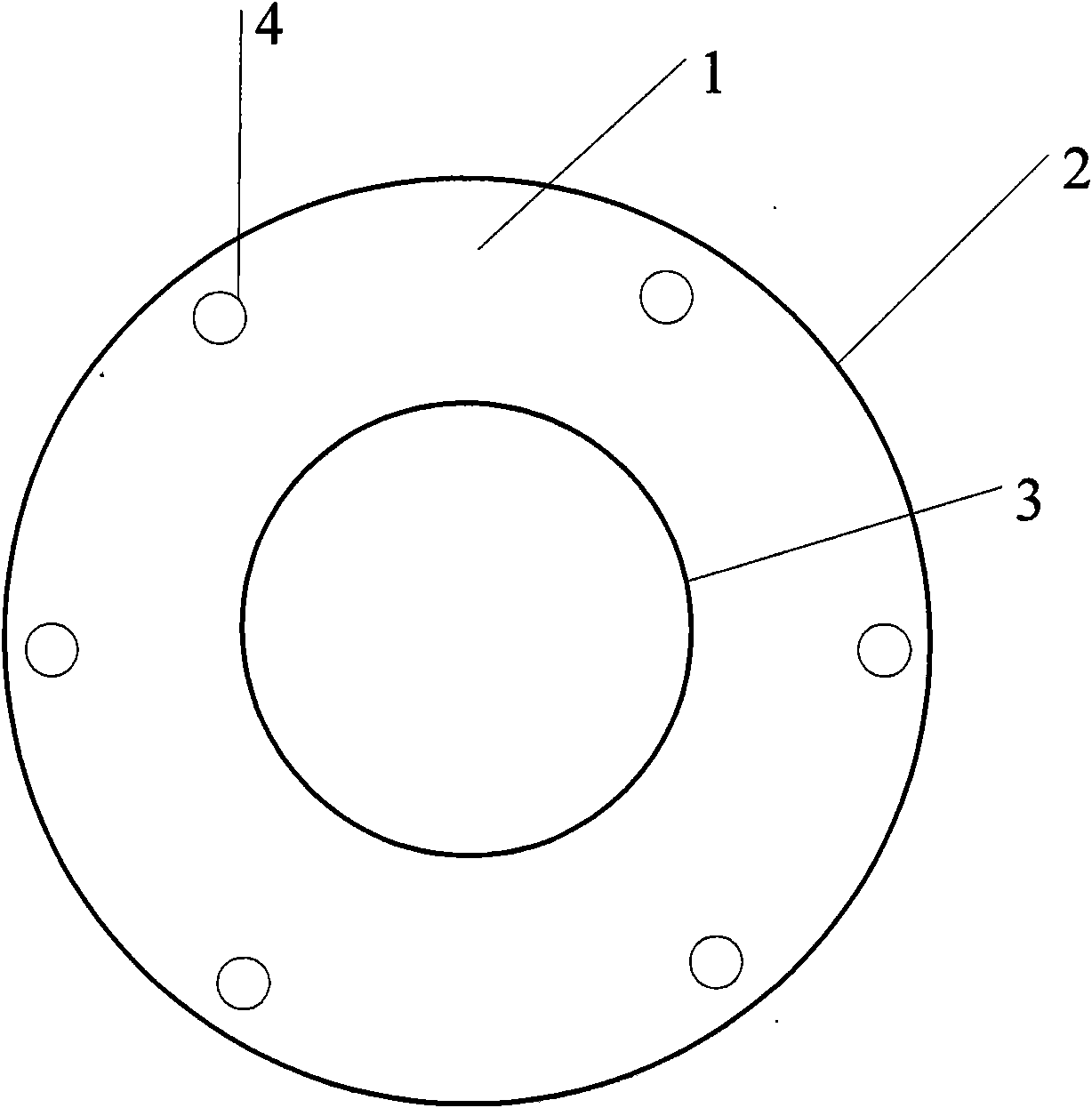

[0021] The structure of the barrel-shaped continuous casting tundish is as follows: figure 1 and figure 2 As shown, it includes a circular bottom surface and a cylindrical side wall. The middle part of the circular bottom surface is provided with a cylindrical dam, and the bottom end of the cylindrical dam is connected with the circular bottom surface. Each tapping hole is evenly distributed on the circular bottom surface and has the same diameter, and the center of each tapping hole is located on a circle coaxial with the circular dam; the axis of the cylindrical dam is in line with the circular bottom surface Axes are the same axis.

[0022] The inner diameter of the cylindrical side wall is 1.635m, the height of the cylindrical side wall is 0.85m, the ratio of the height to the inner diameter is 1:1.92, the inner diameter of the cylindrical retaining dam is 0.9m, and the ratio of the inner diameter of the cylindrical side wall is 1 : 1.82; the height of the cylindrical r...

Embodiment 2

[0031] The structure of the barrel-shaped continuous casting tundish is the same as that in Embodiment 1, the difference is that there are four tap holes on the circular bottom surface around the cylindrical dam, and the center of each tap hole is located in a center coaxial with the circular dam. circle on.

[0032] The inner diameter of the cylindrical side wall is 1.68m, the ratio of the height of the cylindrical side wall to the inner diameter is 1:2.2, and the ratio of the inner diameter of the cylindrical side wall to the inner diameter of the cylindrical retaining dam is 1:2; the height of the cylindrical retaining dam and The height ratio of the cylindrical side wall is 1:3.2; the horizontal distance between the center of each tapping hole and the cylindrical side wall is 1 / 100 of the inner diameter of the cylindrical side wall.

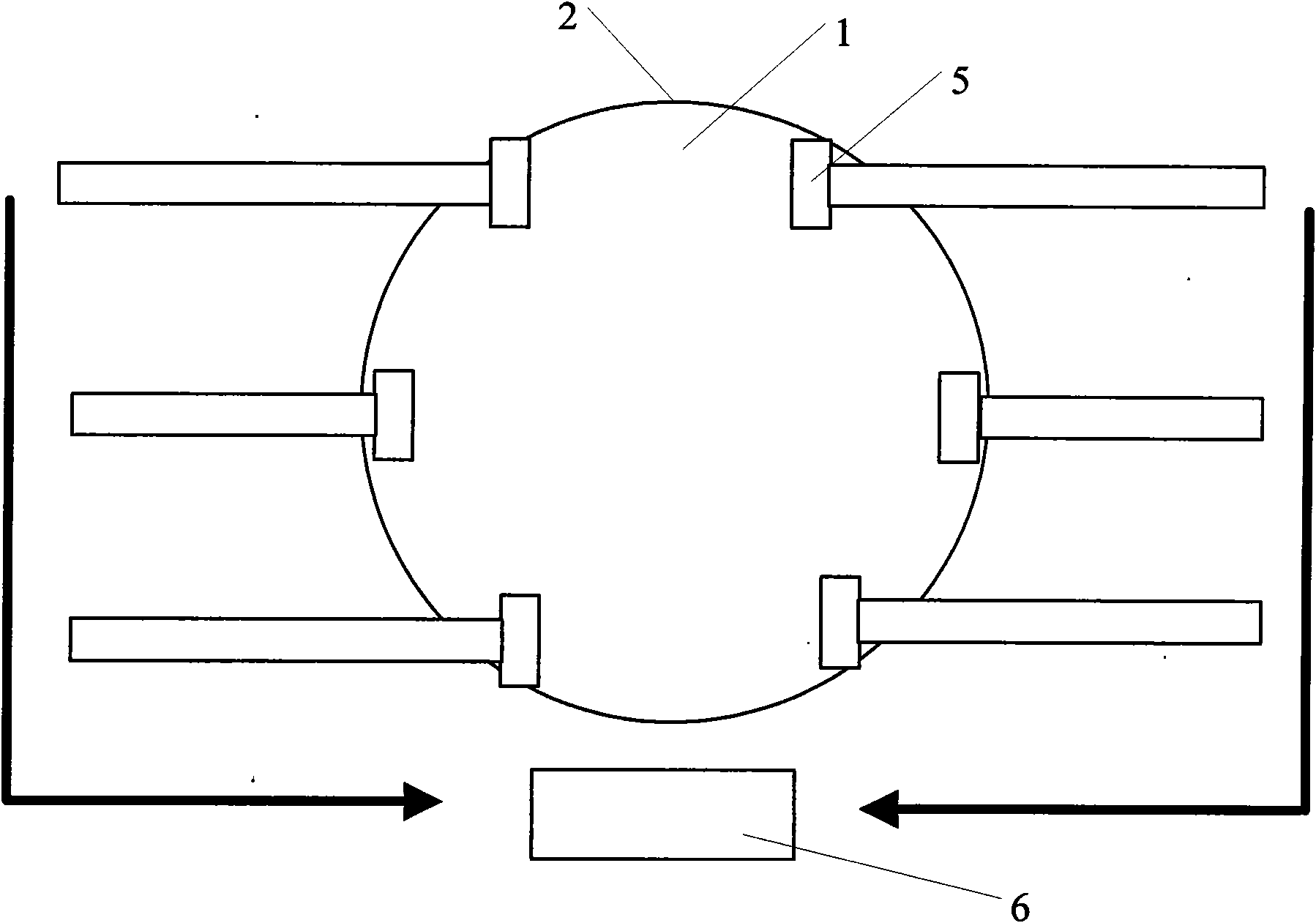

[0033] During continuous casting production, the steel taps of the drum-shaped continuous casting tundish are respectively connected with th...

Embodiment 3

[0036] The structure of the barrel-shaped continuous casting tundish is the same as that of Embodiment 1, except that there are 12 tapping ports on the circular bottom surface, and the center of each tapping port is located on a circle coaxial with the circular retaining dam.

[0037] The inner diameter of the cylindrical side wall is 1.7m, the ratio of the height of the cylindrical side wall to the inner diameter is 1:1.8, the ratio of the inner diameter of the cylindrical side wall to the inner diameter of the cylindrical dam is 1:1.5; the height of the cylindrical dam and The height ratio of the cylindrical side wall is 1:3.8; the horizontal distance between the center of each tapping hole and the cylindrical side wall is 1 / 120 of the inner diameter of the cylindrical side wall.

[0038] In order to reduce the heat loss on the molten steel surface, a cover is provided in the barrel-shaped continuous casting tundish. The lower end of the cover is connected to the top of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com