Silicomethane low-temperature production and byproduct comprehensive recycling process

A technology for silicon methane and by-products, which is applied in the field of low-temperature production of silicon methane and comprehensive recovery of by-products, can solve problems such as hidden dangers of production safety, leakage, low production efficiency, etc., and achieves the effect of solving poor safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

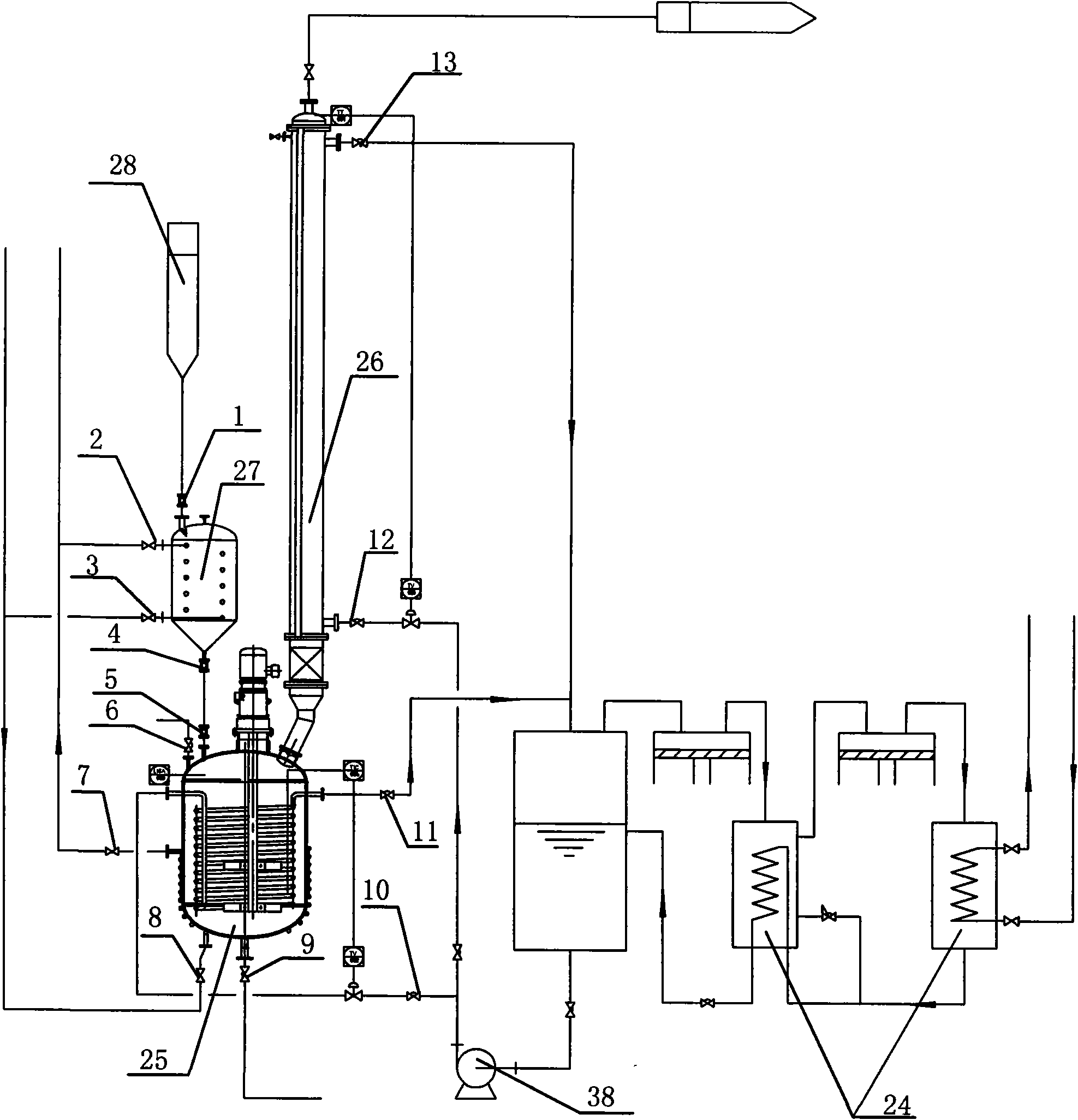

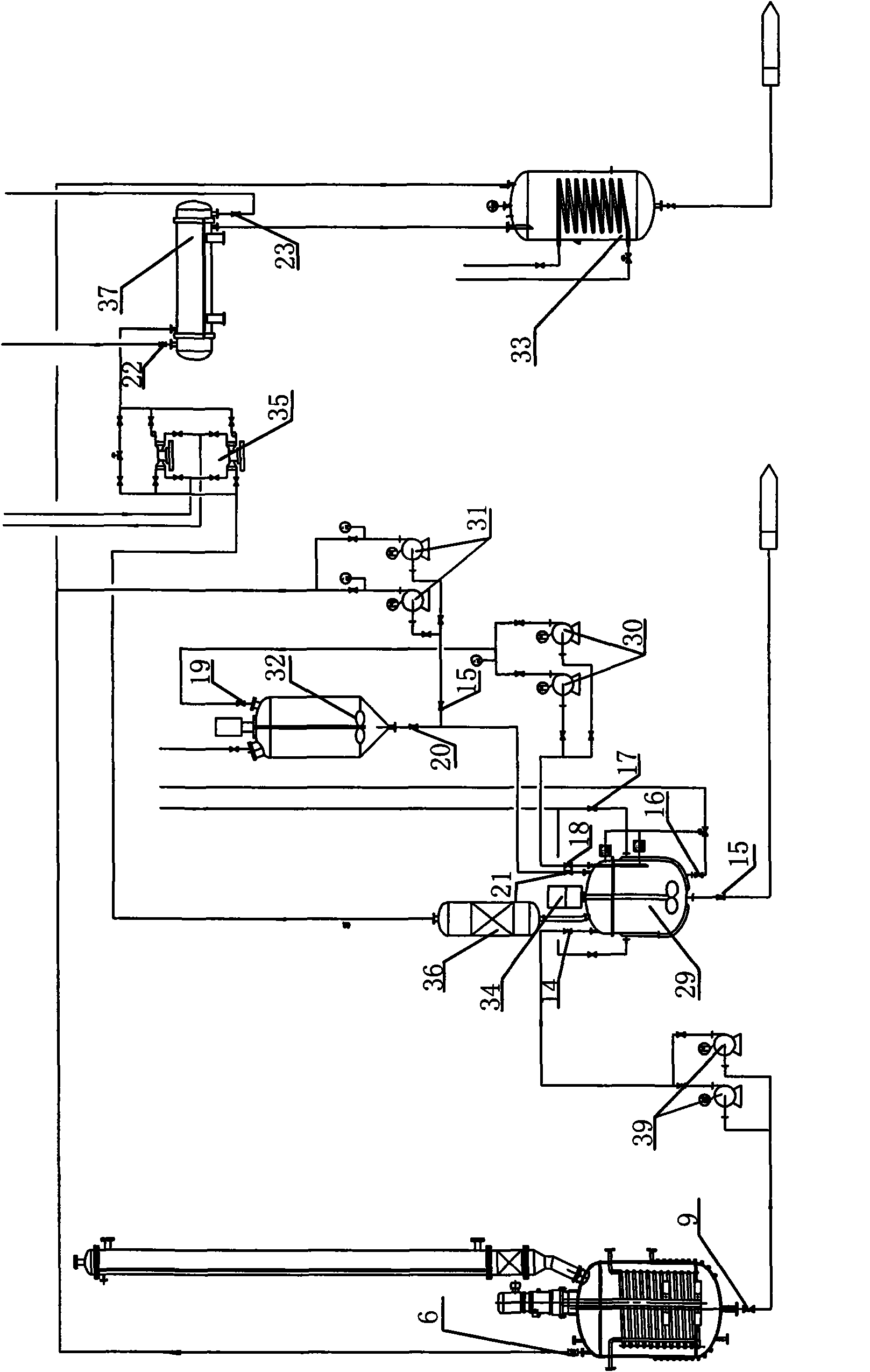

[0021] Below in conjunction with accompanying drawing and specific embodiment, the present invention is described in detail:

[0022] Low-temperature heat exchange technology in the hopper: the coil is used to perform low-temperature heat exchange on the solid powder material entering the hopper, which can effectively reduce the heat of the material during the material addition process, thereby reducing the volatilization of liquid ammonia in the reactor;

[0023] -40°C liquid ammonia low temperature control technology: Magnesium silicide reacts with ammonium chloride to release heat. If it is not removed in time, the temperature of -40°C liquid ammonia will rise, which is not conducive to the complexation of other impurities, and a large amount of ammonia volatilization will be produced at the same time. Not conducive to subsequent silane purification. The two-stage compression refrigeration cycle that uses the ammonia pump to supply liquid passes through the jacket to exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com