Water treatment device of continuous flow ozone/ultraviolet/advanced oxidation

A water treatment device and advanced oxidation technology, applied in the direction of oxidized water/sewage treatment, water/sludge/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of low ozone utilization rate and inability to realize ozone oxidation, etc. Achieve the effects of high ozone utilization rate, easy control and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

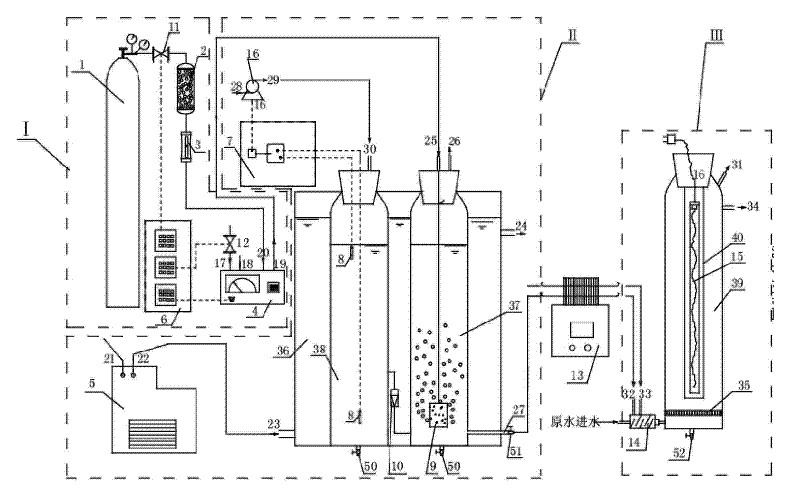

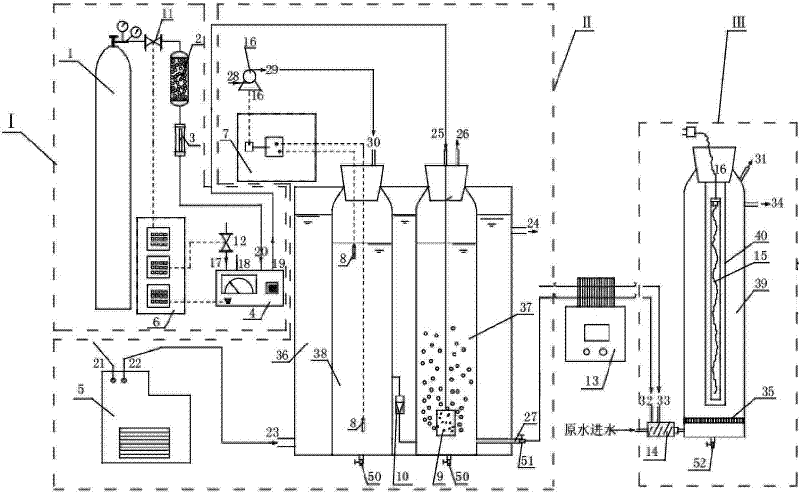

[0008] Specific implementation mode one: as figure 1 As shown, the continuous flow ozone / ultraviolet / advanced oxidation water treatment device described in this embodiment is composed of an ozone generating unit I, a low-temperature water-bath dissolved ozone unit II, an advanced oxidation unit III and a peristaltic pump 13; the low-temperature water-bath dissolved ozone Unit II includes low temperature constant temperature tank 5, water bath box 36, dissolved ozone column 37, water supply column 38, high and low water level electronic water level switch 8, control component 7, air diffusion device (aeration head) 9, check valve 10, and water outlet pipe 27. Make-up water pump 16 and water outlet valve 51; advanced oxidation unit III includes reactor shell 39, quartz water riser 40, ultraviolet lamp 15, microporous water distribution plate 35 and mixer 14; water outlet 22 on low temperature constant temperature tank 5 It is communicated with the water inlet 23 at the bottom of...

specific Embodiment approach 2

[0010] Specific implementation mode two: as figure 1 As shown, the ozone generating unit 1 in this embodiment is composed of an oxygen tank 1, a gas purification and drying column 2, a gas flow meter 3, an ozone generator 4, a controller 6, a first solenoid valve 11 and a second solenoid valve 12, Oxygen tank 1, gas purification and drying column 2 and gas flow meter 3 are connected in sequence, and the pipeline between oxygen tank 1 and gas purification and drying column 2 is provided with a first solenoid valve 11, and the outlet port of gas flow meter 3 is connected to the ozone The oxygen inlet 20 of generator 4 is communicated, and the circulating cooling water inlet 17 of ozone generator 4 is communicated with tap water water source and is provided with second electromagnetic valve 12 between the two; Controller 6 is used for controlling the first electromagnetic valve 11 Open and close and then regulate the flow of oxygen entering the ozone generator 4 by the oxygen inl...

specific Embodiment approach 3

[0011] Specific implementation mode three: as figure 1 As shown, the low-temperature water-bath ozone-dissolving unit II in this embodiment also includes two vent valves 50, and the vent valves 50 are respectively provided on the outer wall of the bottom end of the ozone-dissolving column 37 and the outer wall of the bottom end of the replenishing water column 38. The bottom of dissolved ozone column 37 and replenishing water column 38 is equipped with a vent valve so that it can be cleaned in the future. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com