Preparation method of copolymer of hydroxybutyl vinyl ether and maleic anhydride

A technology of hydroxybutyl vinyl ether and maleic anhydride is applied in the field of preparation of cross-linked copolymers of vinyl ether and maleic anhydride, can solve problems such as complicated processes, and achieve the effects of simple process, few raw materials and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 367ml (3.75 moles) of ethyl acetate and 135ml (1.25 moles) of cyclohexane into the reactor, mix well, heat to 70°C, then add 122ml (1 mole) of hydroxybutyl vinyl ether and 9.8g (0.1 mol) maleic anhydride, then add 0.5g (0.003 mol) of azobisisobutyronitrile dissolved in 10ml cyclohexane solution at a rate of 0.5ml per minute, react at a constant temperature of 65-70°C for 1 hour, and filter off the clear liquid A crosslinked copolymer of maleic anhydride and hydroxybutyl vinyl ether is obtained. The cross-linked copolymer is a colorless and transparent gel product with no odor, a three-dimensional network cross-linked structure, and a viscosity of 2.12×10 4 centipoise.

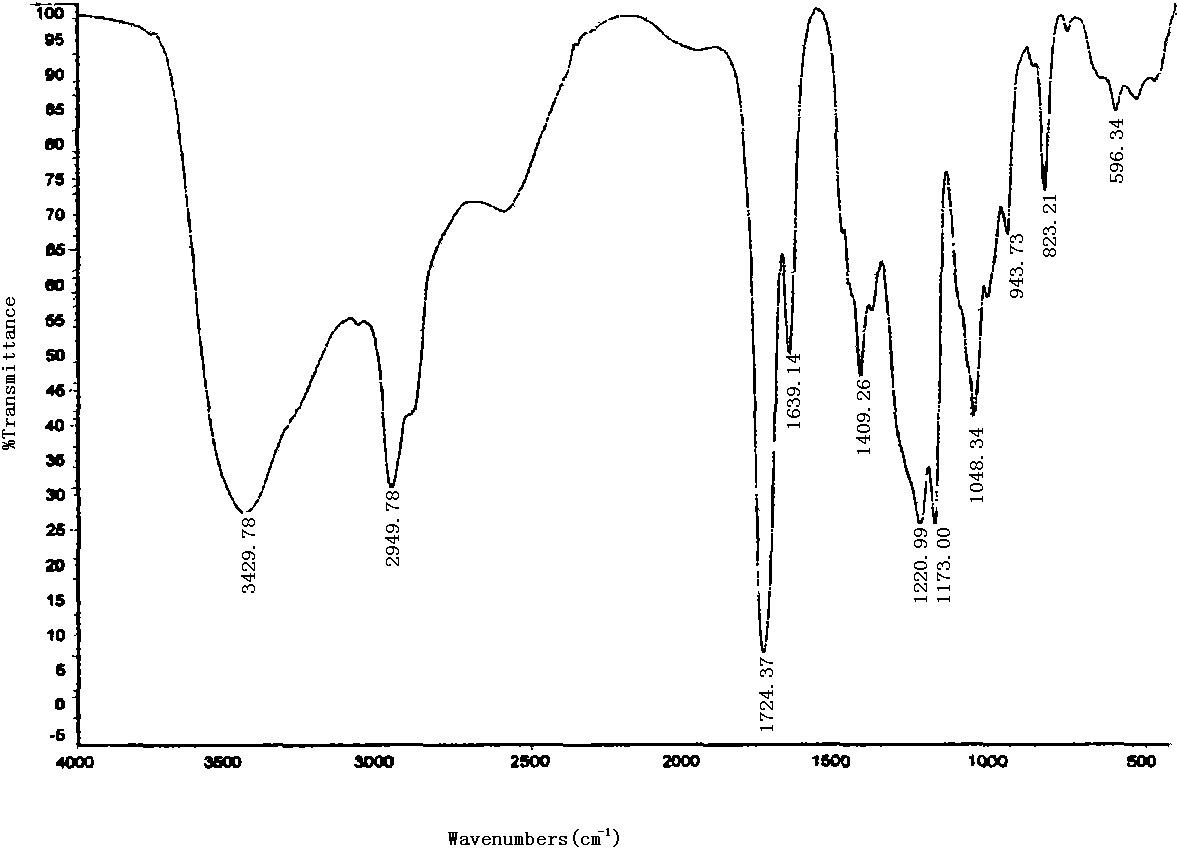

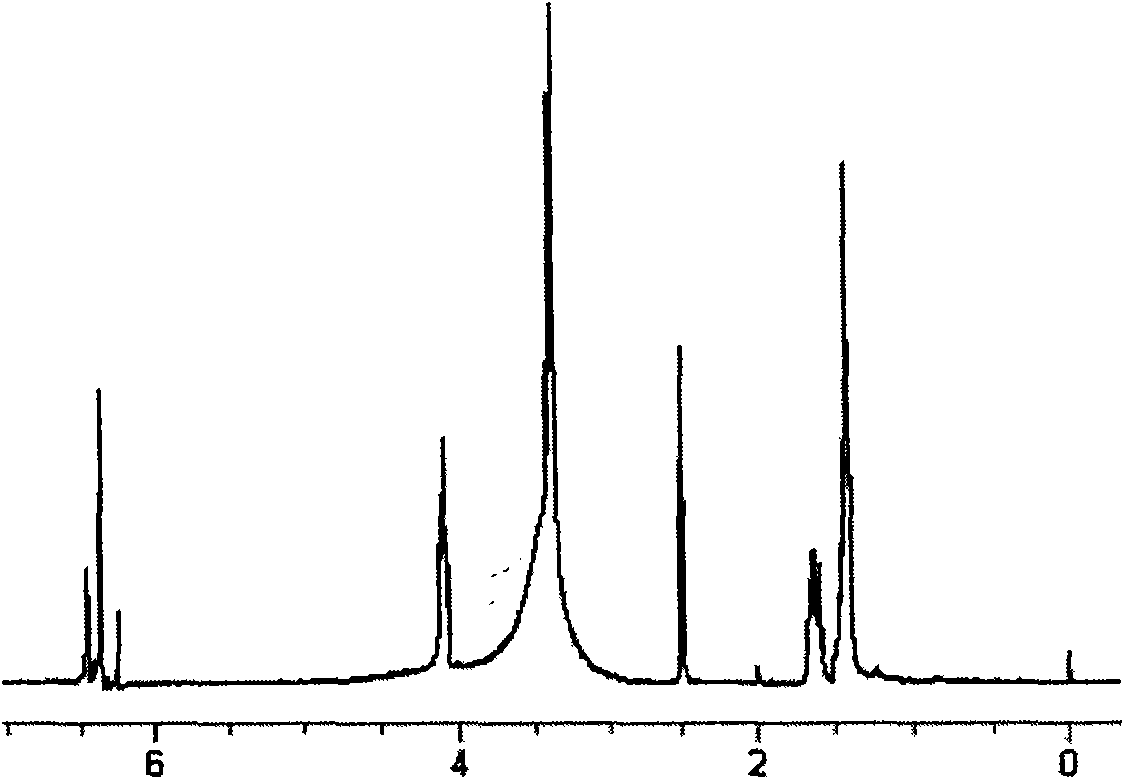

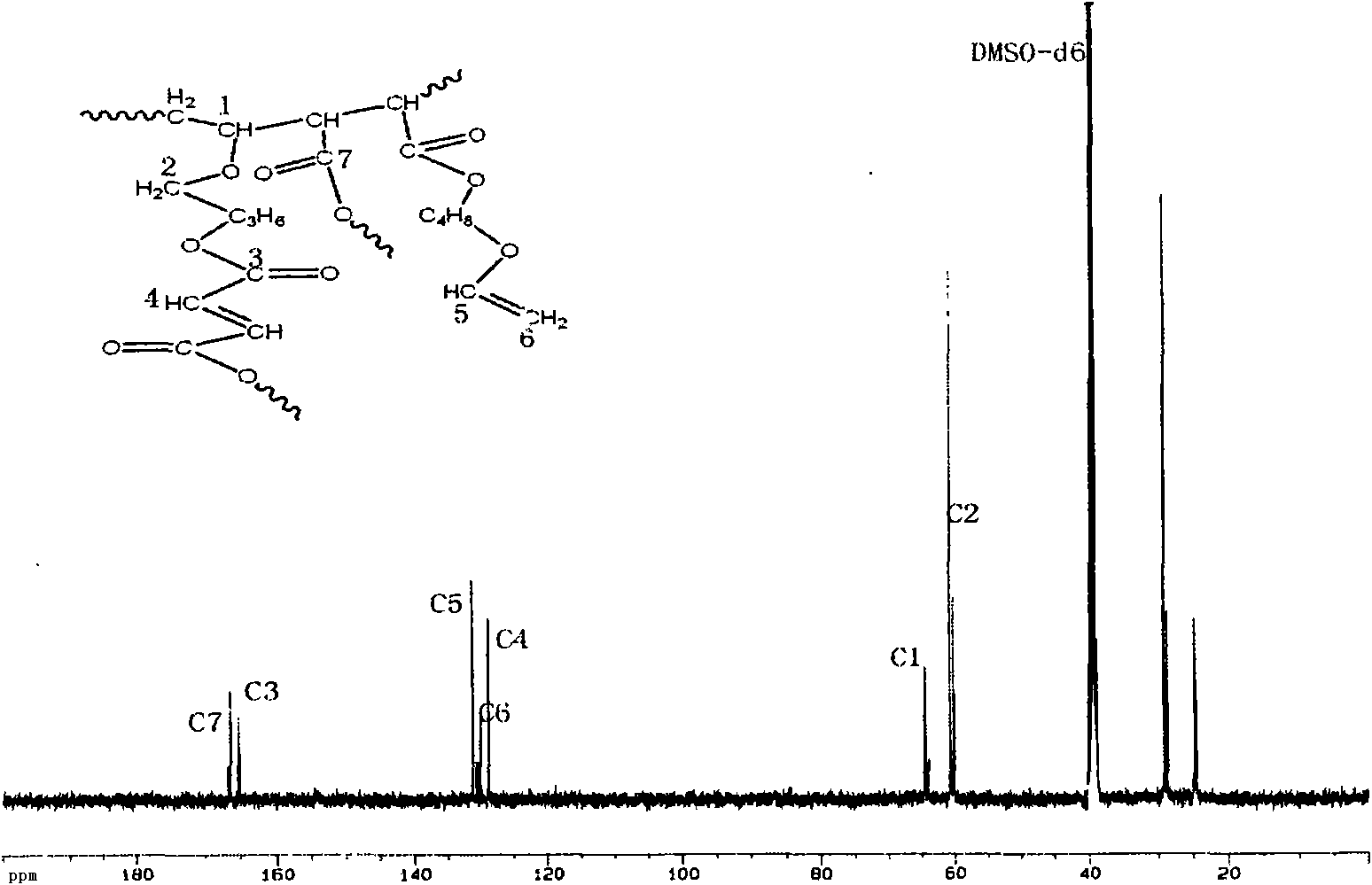

[0025] The infrared spectrum of the resulting product is shown in figure 1 Shown, H NMR spectrum and carbon spectrum see figure 2 , image 3 shown. from figure 1 It can be seen in the obtained product that there is no acid anhydride in the alternating copolymer at 1863cm -1 and 1782cm -1 The...

Embodiment 2

[0027] Add 122ml (1.25 moles) of ethyl acetate and 405ml (3.75 moles) of cyclohexane into the reactor, mix well, heat to 60°C, then add 61ml (0.5 moles) of hydroxybutyl vinyl ether and 9.8g (0.1 mol) maleic anhydride, then add 10ml of cyclohexane solution in which 0.61g (0.0015mol) dodecanoyl peroxide has been dissolved at a rate of 0.5ml per minute, react at a constant temperature of 60°C ± 2°C for 3 hours, and filter off The supernatant yielded a cross-linked copolymer of maleic anhydride and hydroxybutyl vinyl ether. The cross-linked copolymer is a colorless, transparent gel product with no odor, a three-dimensional network cross-linked structure, and a viscosity of 1.72×10 4 centipoise.

Embodiment 3

[0029] Add 36.7ml (0.375 moles) of ethyl acetate and 40.5ml (0.375 moles) of cyclohexane into the reactor, mix well, heat to 50°C, then add 13ml (0.1 moles) of hydroxybutyl vinyl ether and 9.8g (0.1 mole) maleic anhydride; then add 10 ml of cyclohexane solution in which 0.083 g (0.0005 mole) of azobisisobutyronitrile has been dissolved at a rate of 0.5 ml per minute, react at a constant temperature of 50 to 55 ° C for 5 hours, filter The supernatant was removed to obtain a cross-linked copolymer of maleic anhydride and hydroxybutyl vinyl ether. The cross-linked copolymer is a colorless, transparent gel product with no odor, a three-dimensional network cross-linked structure, and a viscosity of 1.33×10 4 centipoise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com