Method for synthesizing gallium phosphide polycrystal

A synthesis method and gallium phosphide technology, which are applied in chemical instruments and methods, polycrystalline material growth, single crystal growth, etc., can solve problems such as human health hazards, explosive tubes, and high-frequency oscillation tubes are easily damaged, and achieve improved production efficiency. Efficiency and quality, reducing the number of tube explosions, and making it difficult for electrodes to ignite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

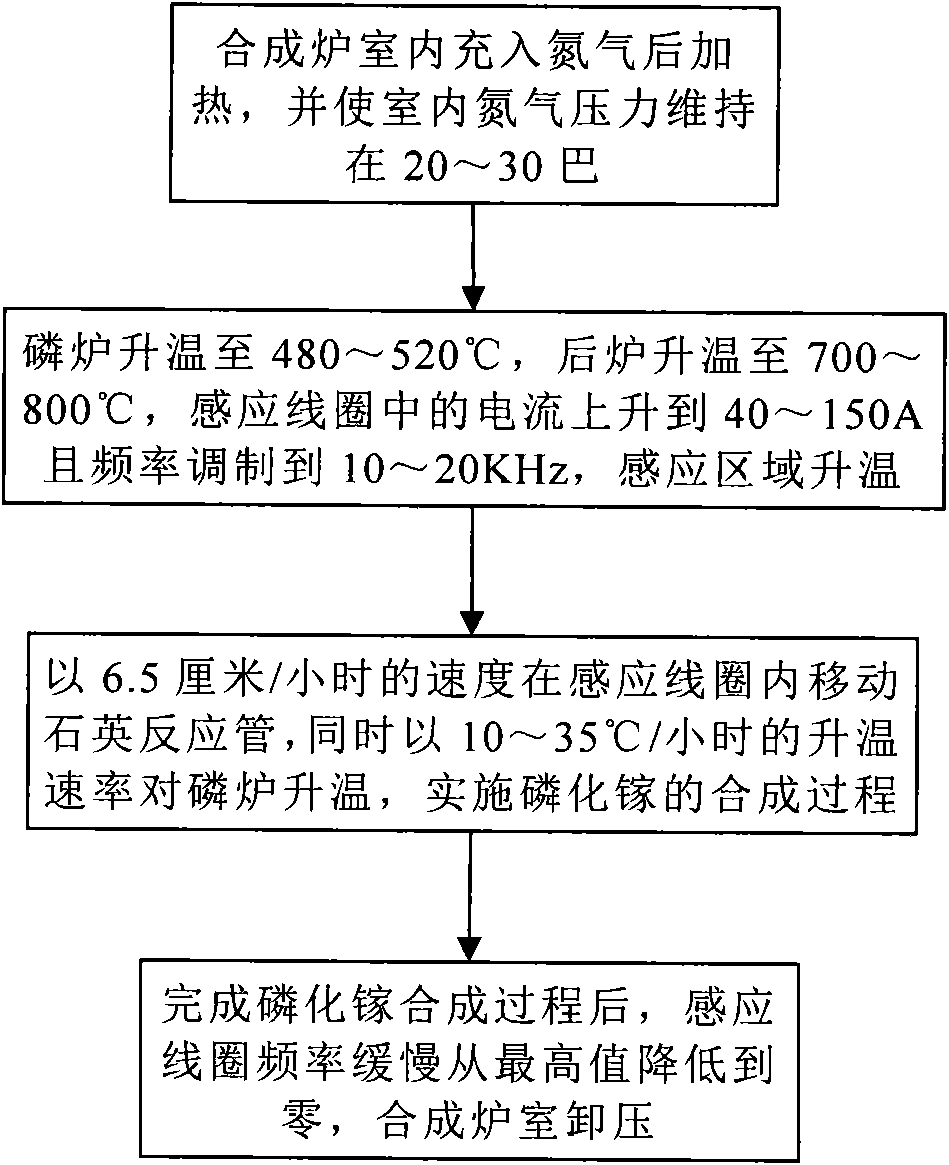

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] Such as figure 1 As shown, the gallium phosphide polycrystalline synthesis method of the present invention comprises steps:

[0020] Step 1: Fill the chamber of the synthesis furnace with 5-10 bars of nitrogen and then heat, and keep the pressure of the nitrogen in the chamber of the synthesis furnace within the range of 20-30 bars.

[0021] Step 2: Raise the temperature of the phosphorus furnace to the range of 480-520°C, raise the temperature of the rear furnace to the range of 700-800°C, raise the current in the induction coil to the range of 40-150A and adjust the frequency to 10 In the range of ~20KHz to heat up the induction area in the induction coil. Generally, it takes 50-60 minutes to raise the current in the induction coil to the range of 40-150A.

[0022] Step 3: After confirming that the temperature of the phosphorus furnace and the rear furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com