Method for stably desulphurizing Hg(II) in gypsum

A desulfurization gypsum, stable technology, applied in the field of environmental engineering, can solve problems such as potential safety hazards, and achieve the effect of reducing the concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

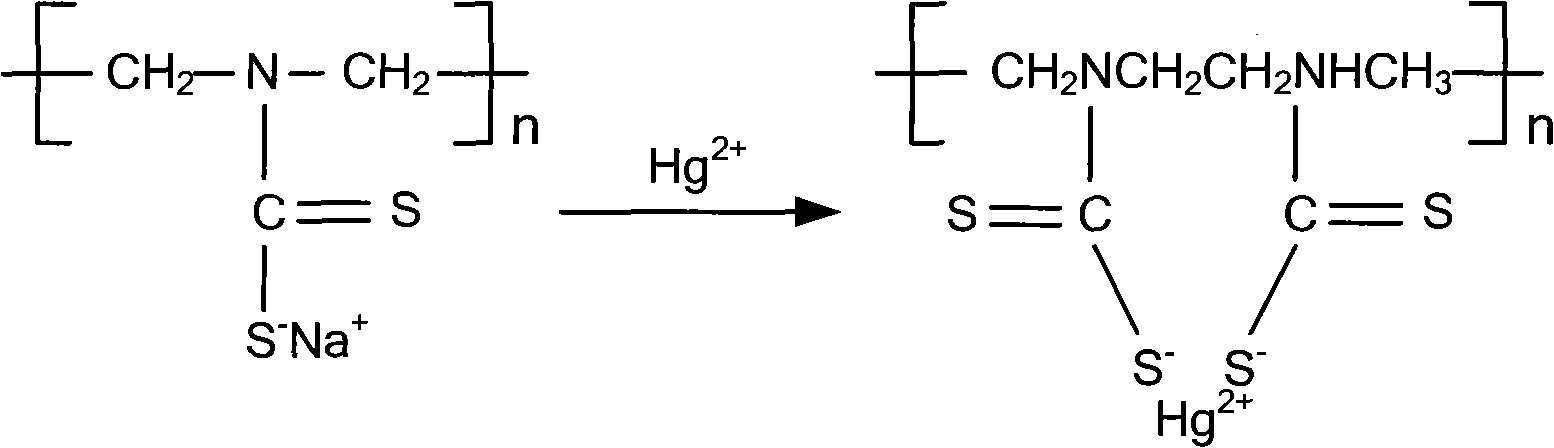

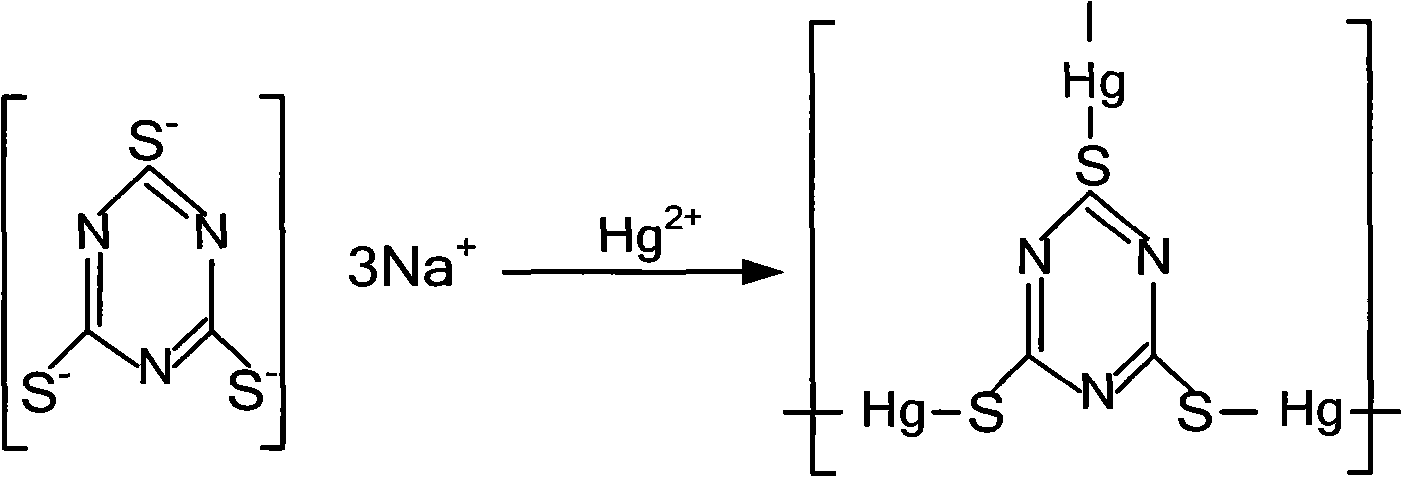

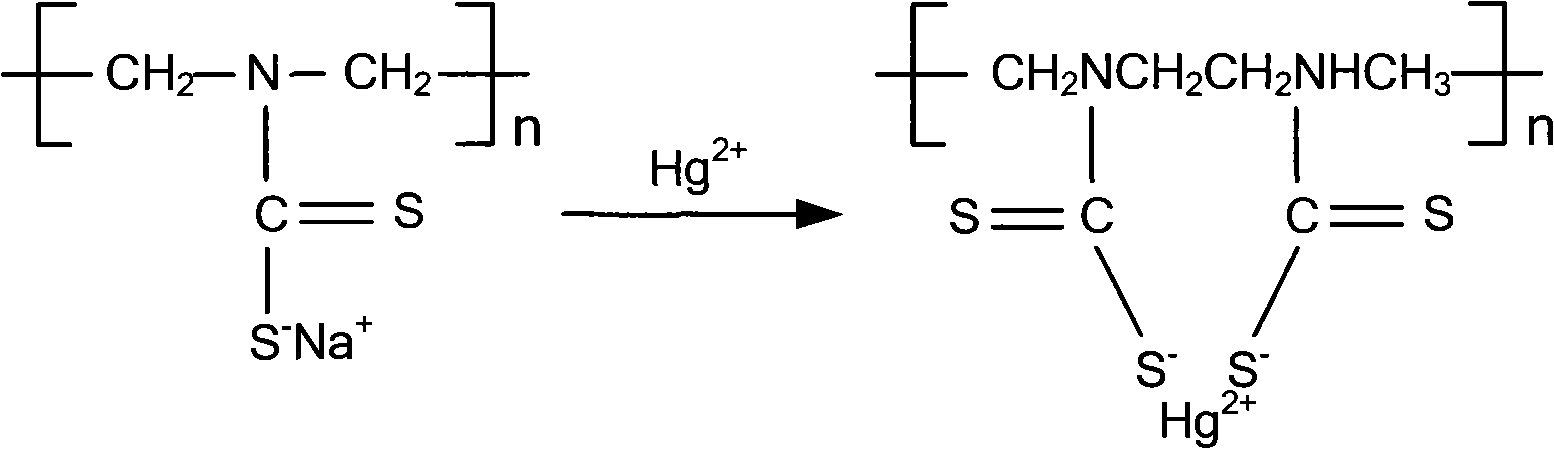

Method used

Image

Examples

Embodiment 1

[0020] Add TMT to the desulfurized gypsum slurry at a ratio of 0.6gTMT:1gHg (the actual amount added is 0.6mg / L), and the mercury removal rate of the desulfurized liquid after the reaction is 91.2%. Soak the filtered gypsum in the simulated acid rain of pH=5 for 24 hours, the mercury content in the gypsum before soaking is 68.4ug / g gypsum, after soaking 2+ The dissolution rate is 0.31ug / g gypsum, and the dissolution rate is 0.45%.

Embodiment 2

[0022] Add TMT to the desulfurized gypsum slurry at a ratio of 0.8gTMT:1gHg (the actual amount added is 0.8mg / L), and the mercury removal rate of the desulfurized liquid after the reaction is 94.2%. Soak the filtered gypsum in the simulated acid rain of pH=5 for 24 hours, the mercury content in the gypsum before soaking is 70.7ug / g 2+ The dissolution amount of the compound is 0.16ug / g gypsum, and the dissolution rate is 0.22%.

Embodiment 3

[0024] Add TMT to the desulfurized gypsum slurry at a ratio of 1gTMT:1gHg (the actual amount added is 1.0 mg / L), and the mercury removal rate of the desulfurized liquid after the reaction is 97.0%. Soak the filtered gypsum in the simulated acid rain of pH=5 for 24 hours, the mercury content in the gypsum before soaking is 72.7ug / g 2+ The dissolution amount of the compound is 0.15ug / g gypsum, and the dissolution rate is 0.21%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com