Method for preparing 2-alkyl carboxylic acid

A technology of alkyl carboxylic acid and alkyl group, applied in the field of preparing 2-alkyl carboxylic acid, can solve the problems of expensive raw materials, high cost and rare, and achieve the effects of convenient operation, less by-products and high production process yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

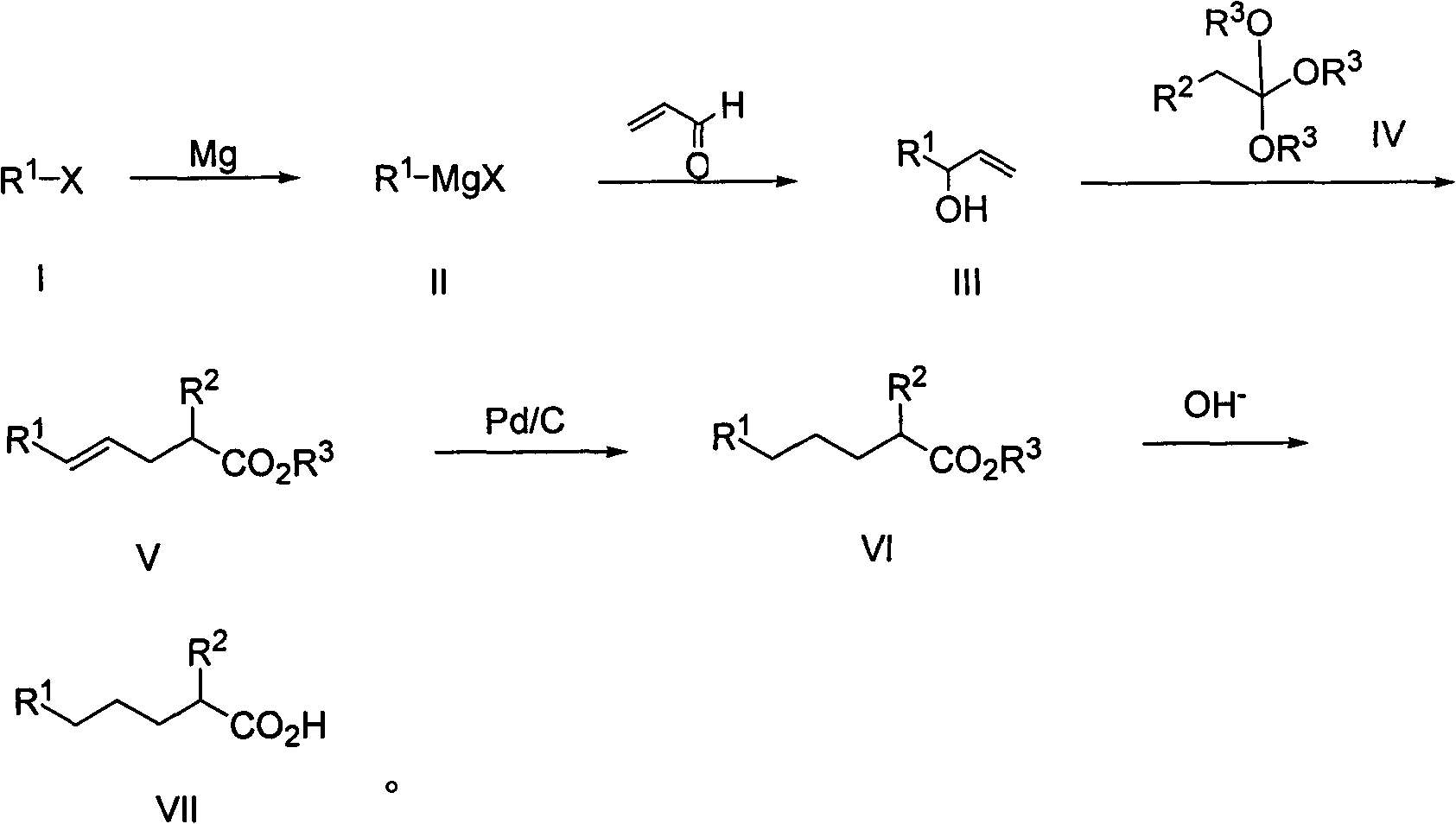

Method used

Image

Examples

Embodiment 1

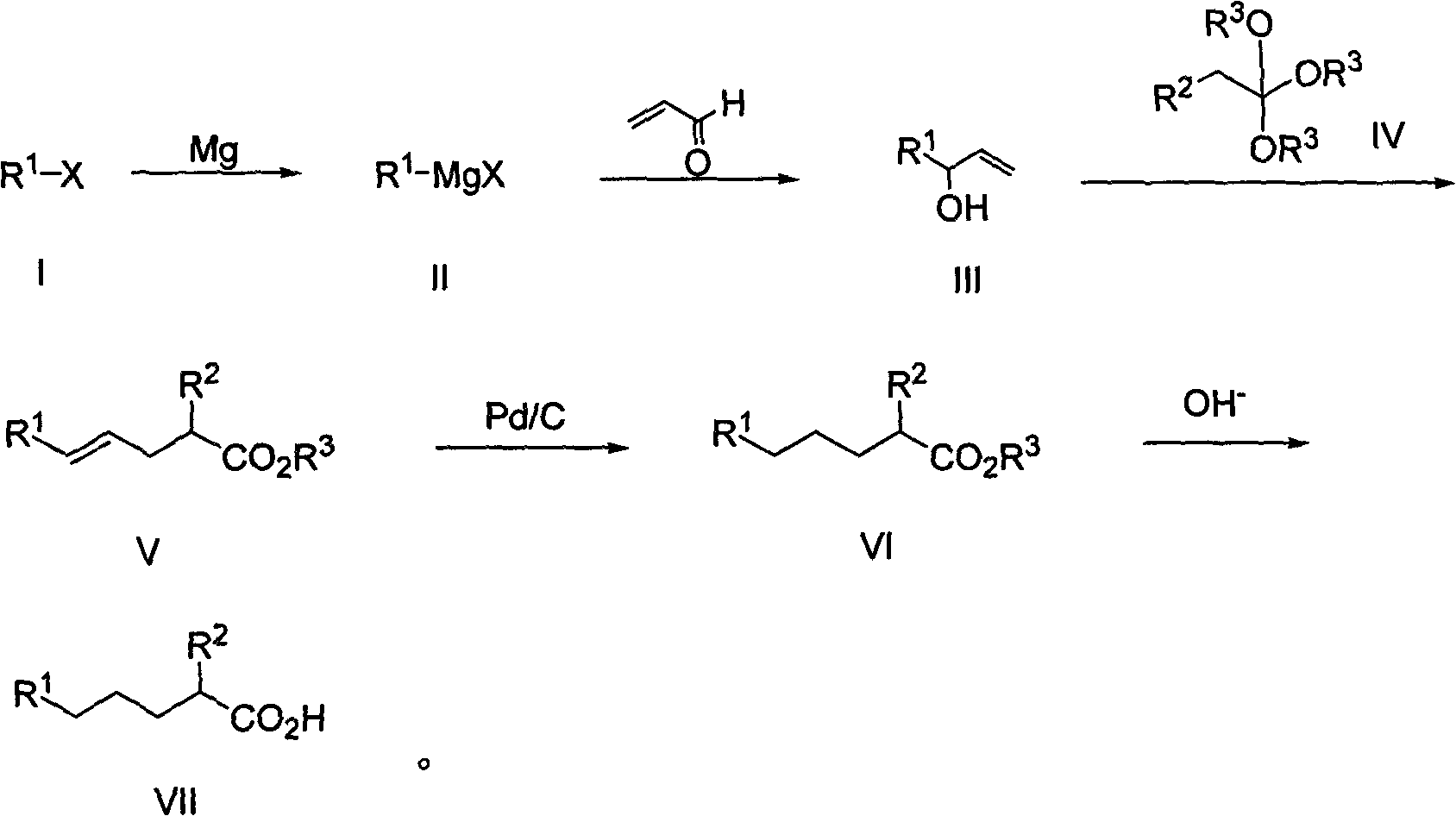

[0027] A kind of method for preparing 2-alkyl carboxylic acid, when R 1 is n-hexyl, R 2 is methyl, R 3 When being a methyl group, the general reaction formula is as follows:

[0028]

[0029] The preparation method comprises the following steps:

[0030] The first step: the synthesis of 3-hydroxyl-1-nonene (4):

[0031] Add 3g (0.125mol) of magnesium chips to a 250ml four-necked bottle, add 20ml of tetrahydrofuran (THF), stir under nitrogen protection, add a small grain of iodine (40mg) and 0.5ml of 1,2-dibromoethane as the initiator, heat, System initiation, reaction at 60°C, 13.7 g (0.113 mol) of n-chlorohexane (1) was slowly added dropwise, and the addition was completed in 50 minutes, and the reaction was carried out at 45°C. After 2 hours, GC tracking showed that the reaction of raw materials was complete. Transfer the reaction solution into a 250ml dropping funnel, slowly dropwise add acrolein (3) 9.5g, (0.170mol) and THF (50ml) mixture, control the temperature at...

Embodiment 2

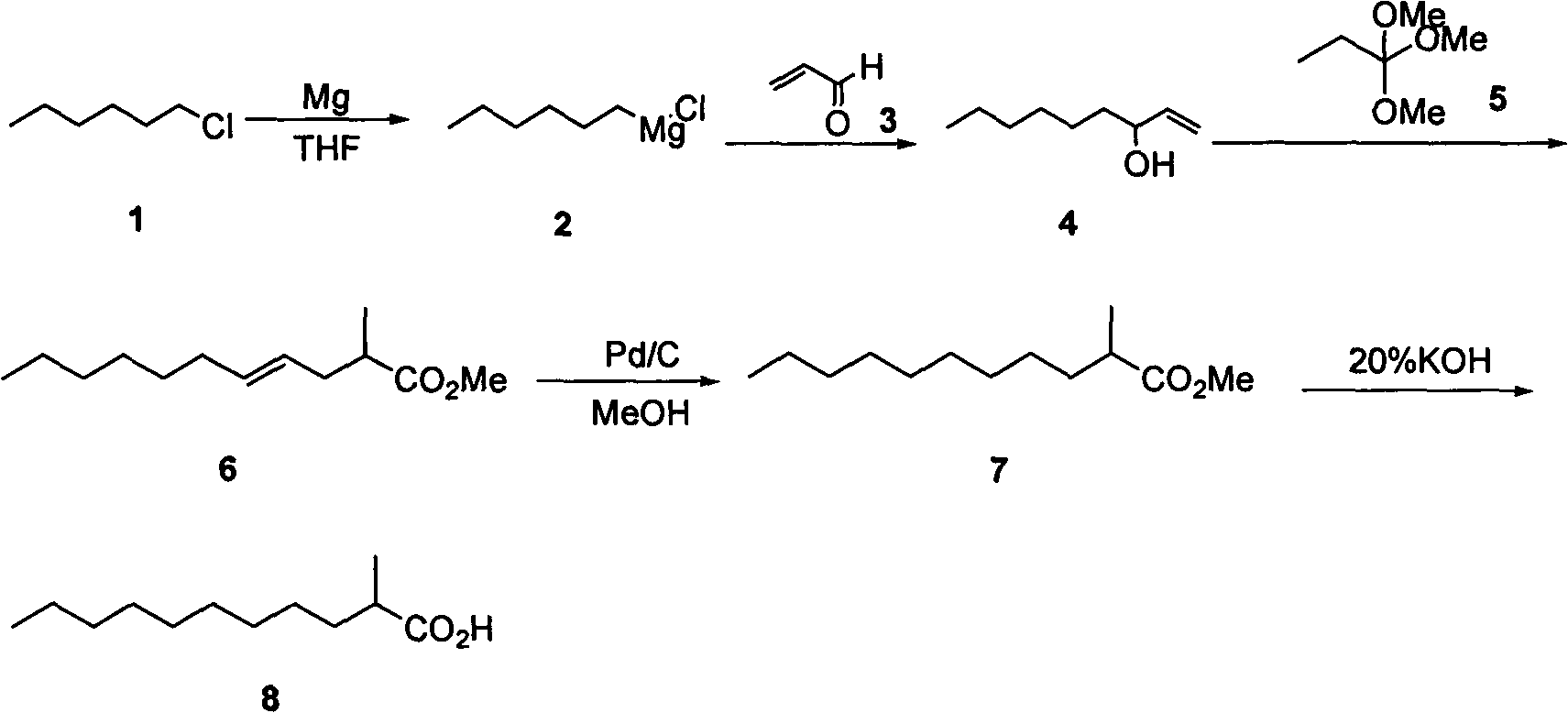

[0054] A kind of method for preparing 2-alkyl carboxylic acid, when R 1 is n-propyl, R 2 is ethyl, R 3 When being a methyl group, the general reaction formula is as follows:

[0055]

[0056] The preparation method comprises the following steps:

[0057] The first step: the synthesis of 3-hydroxyl-1-hexene (11):

[0058] Add 5g (0.208mol) magnesium chips to a 250ml four-necked bottle, add 30ml THF, stir under nitrogen protection, add a small grain of iodine (about 40mg) and 0.5ml of 1,2-dibromoethane as the initiator, heat, and the system initiates , reacted at 60°C, slowly added 14.9g (0.189mol) of n-chloropropane (9) dropwise, and the addition was completed in 50 minutes. After reacting at 40°C for 2 hours, GC tracking showed that the reaction of the raw materials was completed. The reaction solution was slowly added dropwise to a mixture of 15.9 g (0.283 mol) of acrolein (3) and THF (50 ml), the temperature was controlled at 5-10°C, the dropwise addition was complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com