Flow passage component of high-temperature high-pressure coal chemical industry

A technology of high temperature and high pressure, overcurrent components, applied in pump components, components of pumping devices for elastic fluids, pumps, etc., can solve the problems of short life, wear of pressure-bearing pump body and pump cover, etc., to reduce vibration , Reduce the effect of scouring and wear, and prevent the effect of blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

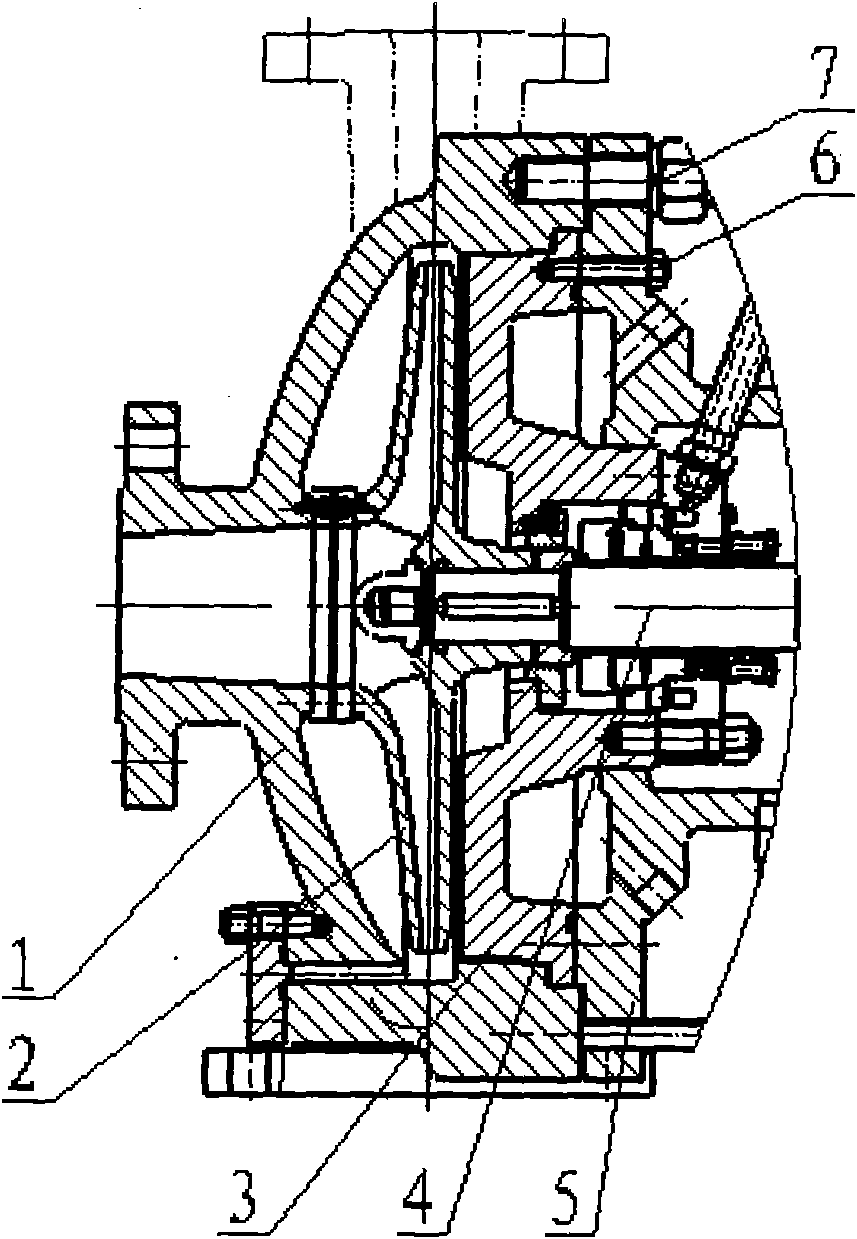

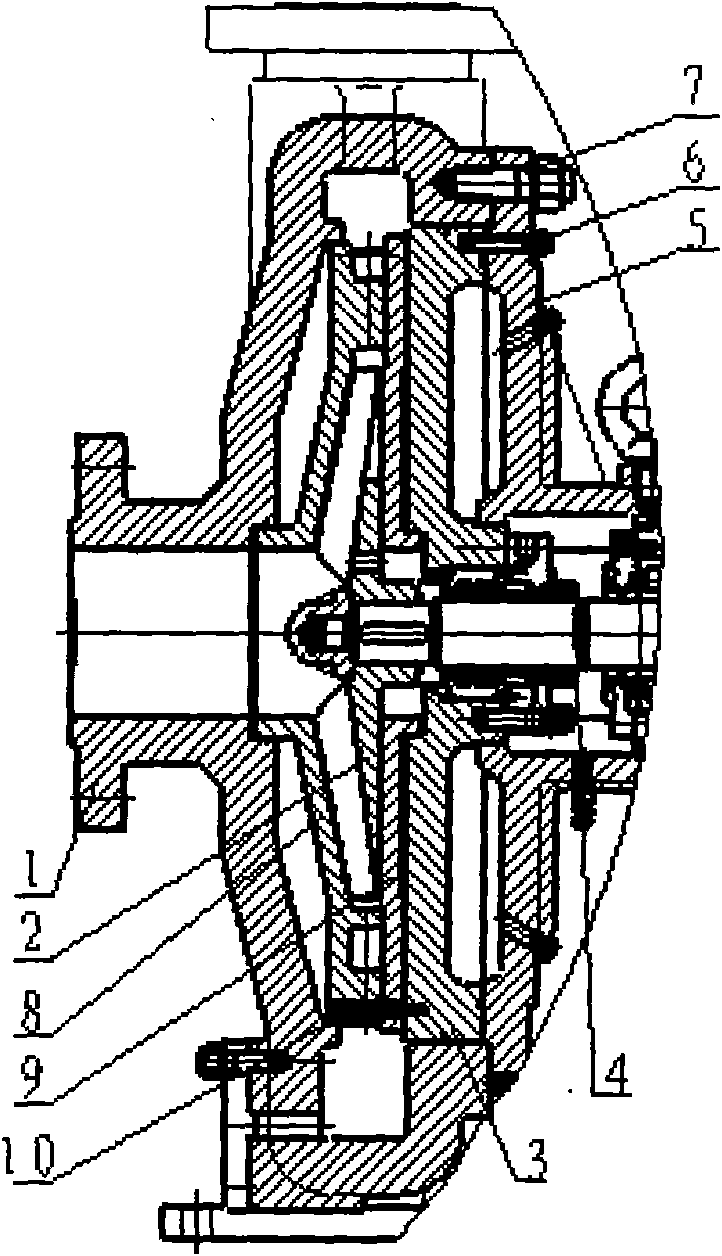

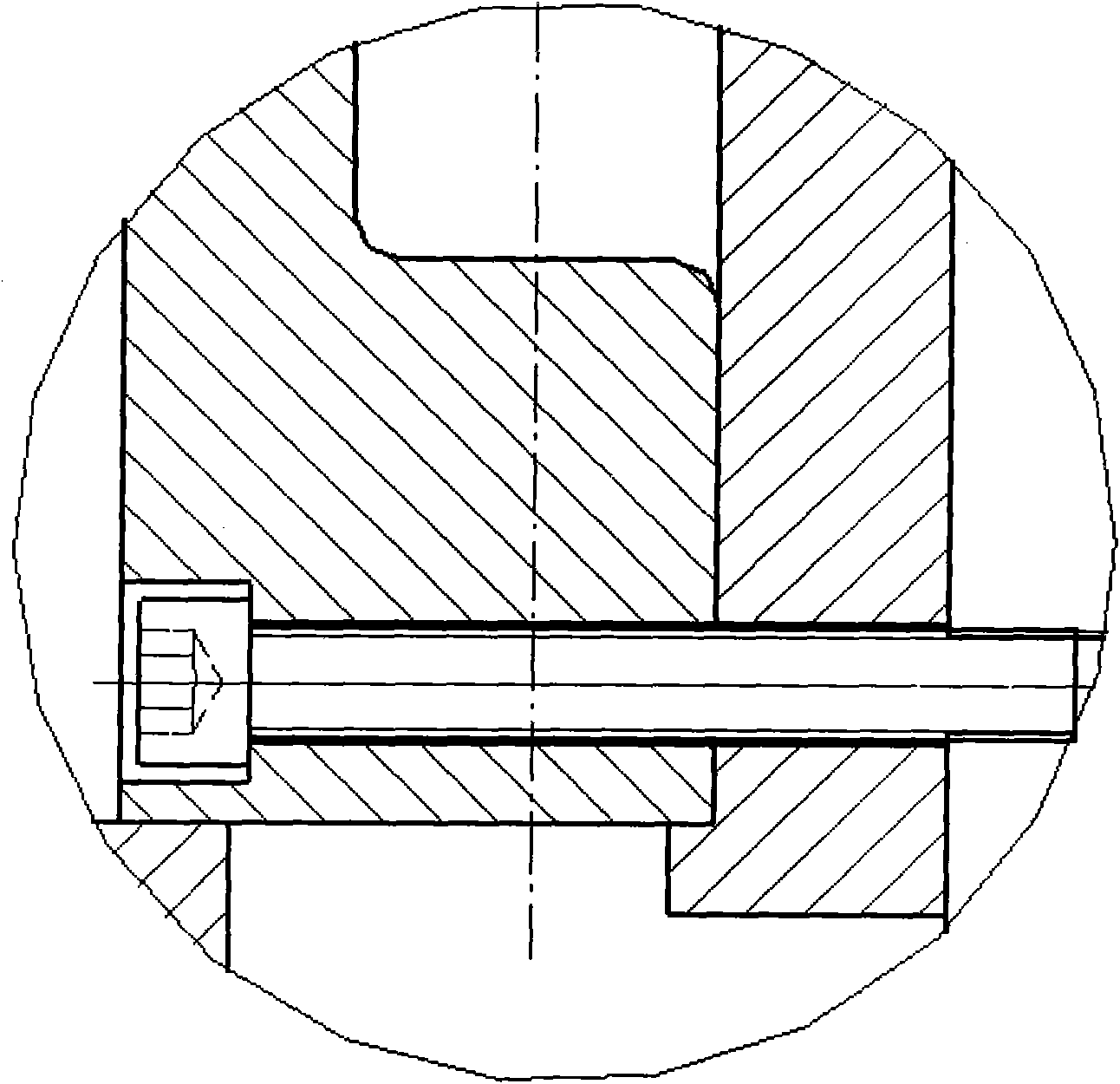

[0026] like figure 2 As shown, the high temperature and high pressure coal chemical slurry pump flow parts of the present invention include impeller 2, guide vane 8, lining plate 9; peripheral equipment includes pump body 1, pump cover 3, pump shaft 4, bracket 5, pump Cover locking stud 6, and pump body locking stud 7; wherein: guide vane 8 has a structure such as Figure 4 , Figure 5 As shown, the guide vane 8 is integrally cast from a wear-resistant metal material. The guide vane 8 is in the shape of a tapered horn. There are five uniformly distributed diffusion channels cast on the guide vane 8. Between the five uniformly distributed diffusion channels There is a cylindrical through hole for positioning; the bell mouth on the left side of the guide vane 8 is processed with a cylindrical outer spigot for matching with the spigot of the pump body 1; 9 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com