Method for controlling etching solution concentration

A control method and etching solution technology, which can be applied in various fluid ratio control, photosensitive material processing and other directions, which can solve the problems of cost, unfriendly manufacturing process, unfavorable market competition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be fully understood through the following examples, so that those skilled in the art can realize the present invention, but the implementation of the present invention is not limited by the following examples.

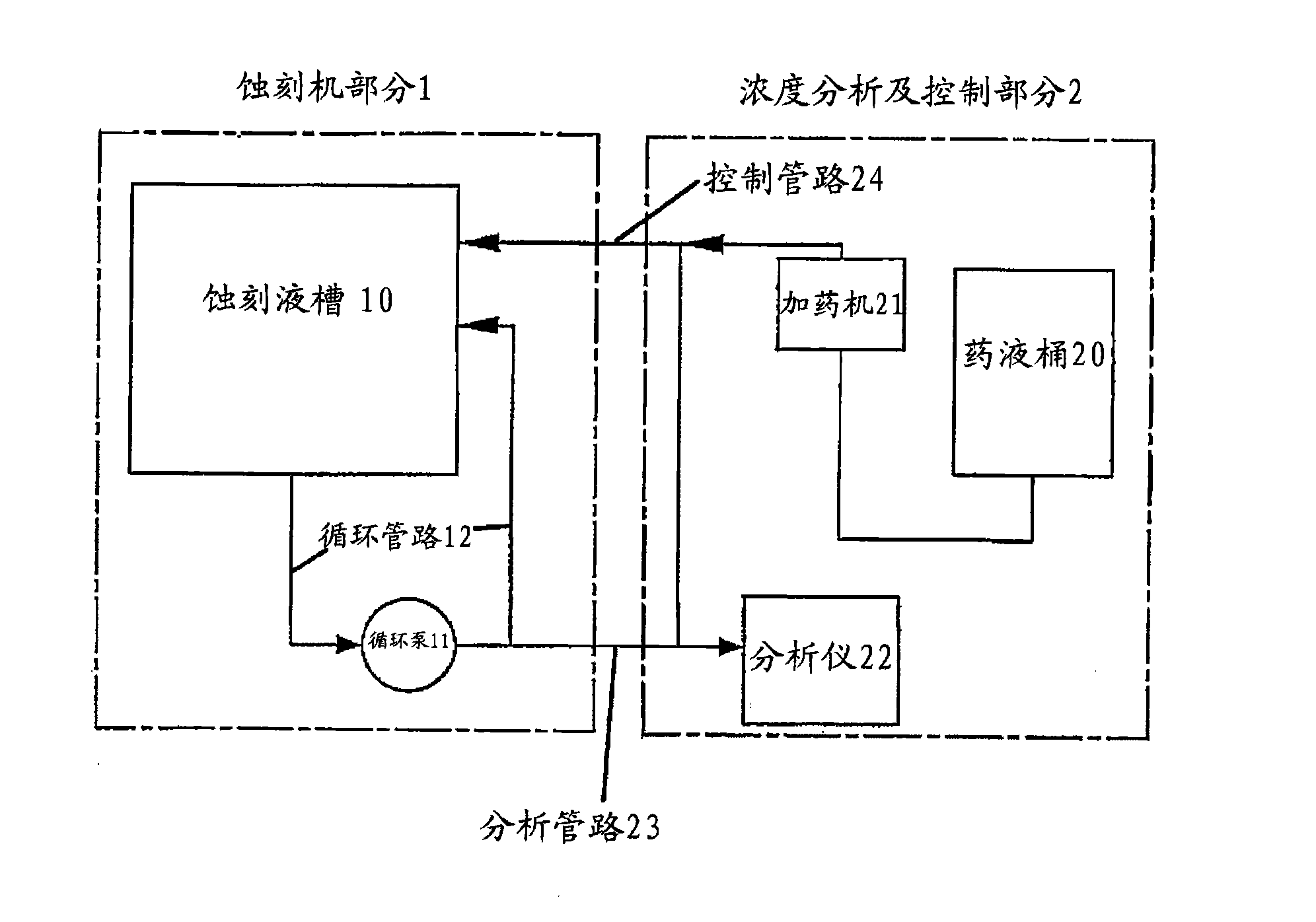

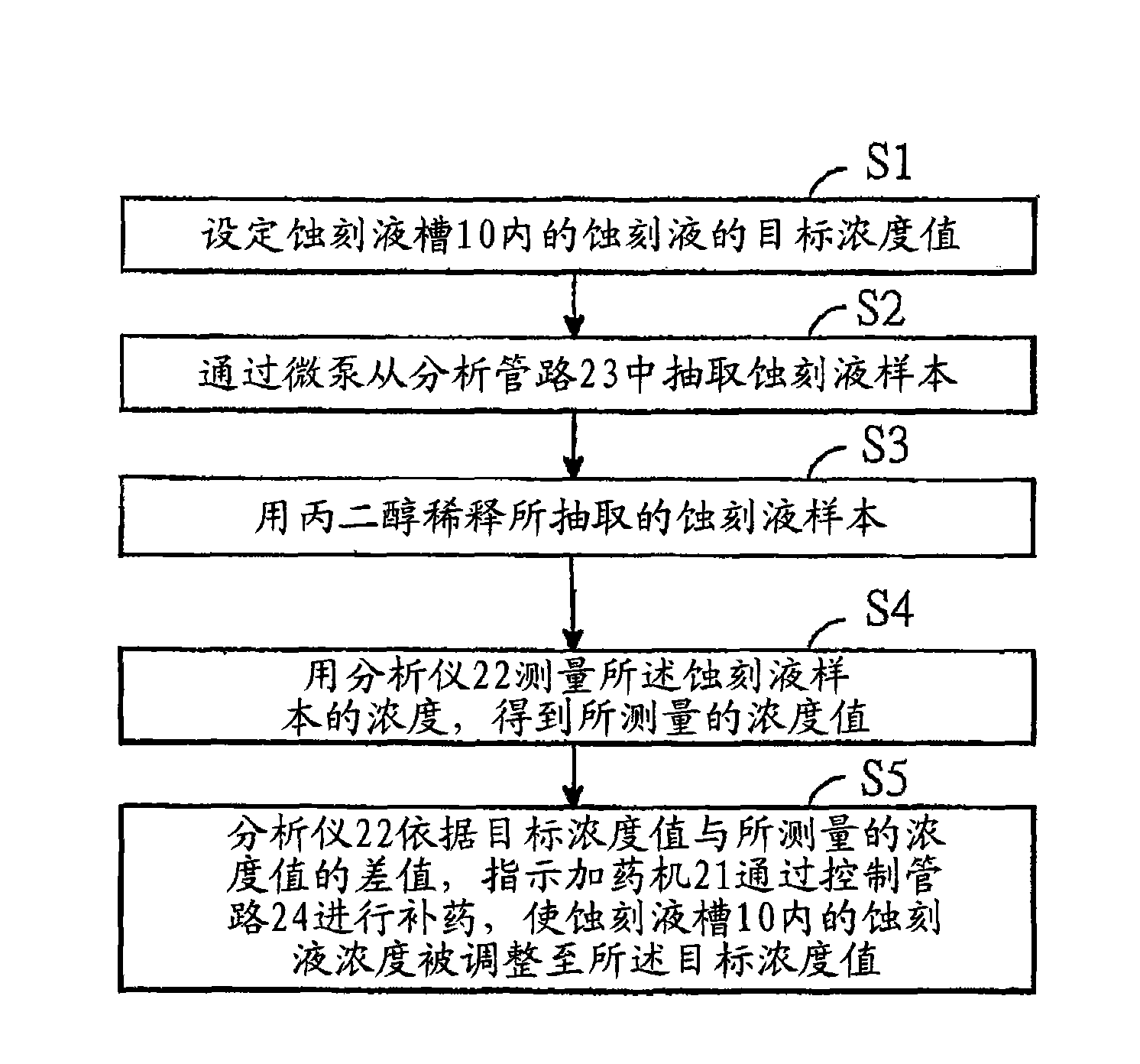

[0033] refer to figure 1 , which is a schematic diagram of the etching solution concentration analysis and control device of the present invention. The etching machine part 1 is generally a conventional etching machine structure, which includes an etching solution tank 10 , a circulation pump 11 , and a circulation pipeline 12 . The etchant tank 10 is used to store the etchant to carry out the etching reaction. The etchant in the etchant tank 10 includes commonly used alkaline solutions such as sodium hydroxide, potassium hydroxide, ammonia and mixed solutions thereof, and such as hydrochloric acid, hydrofluoric acid, etc. Commonly used acid solutions such as acid, nitric acid, acetic acid, phosphoric acid, sulfuric acid and their mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com