Rectifier chamber cooling system and method for cooling, air discharging and radiating of same

A rectifier room and cooling system technology, applied in the field of comprehensive management system, can solve the problems of unsatisfactory ventilation and heat dissipation, large energy consumption of rectifiers, etc., achieve scientific and reasonable cooling method, improve cooling effect, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings, and the protection scope of the present invention is not limited by the embodiments.

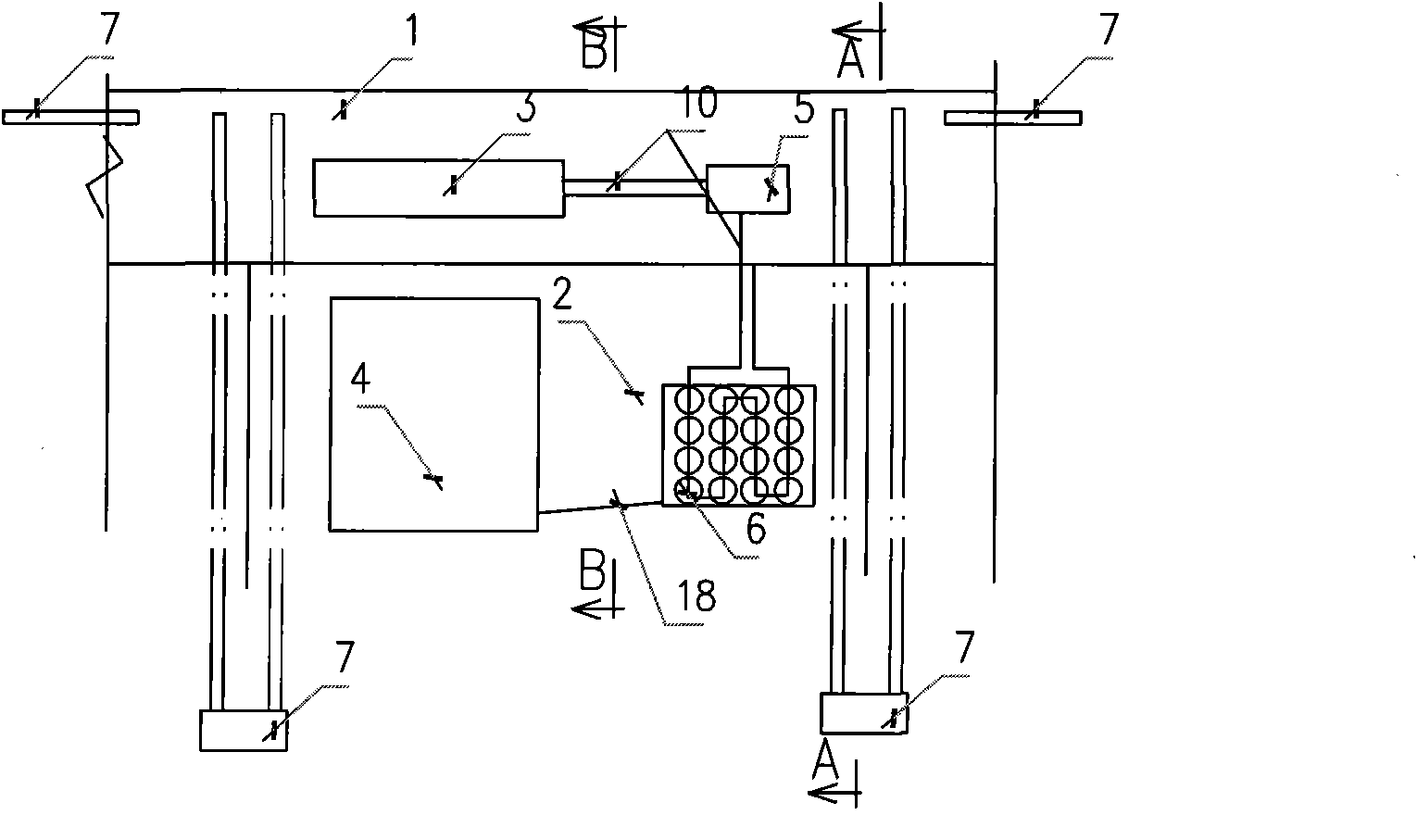

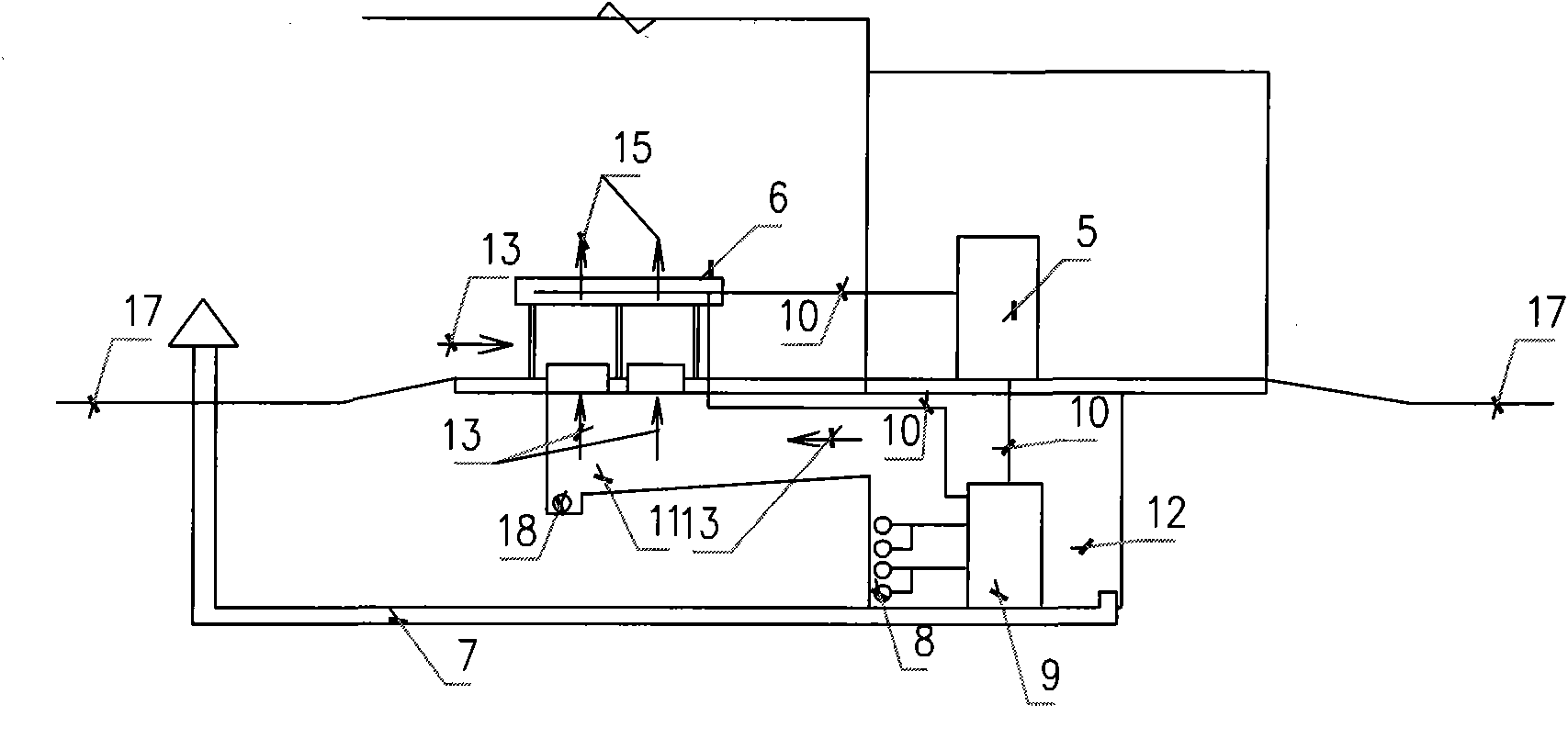

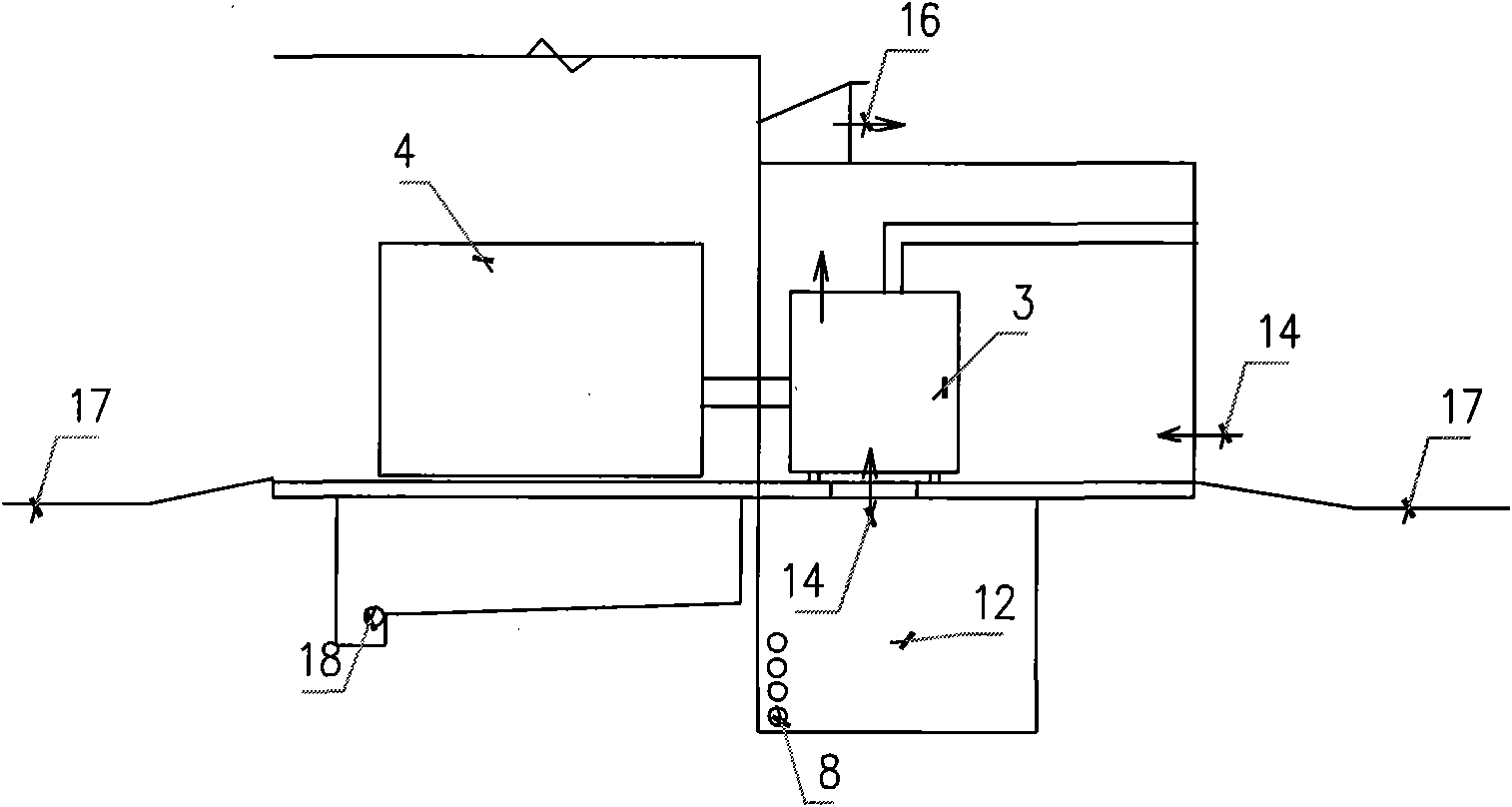

[0026] Such as Figure 1-3 As shown, a long basement 12 is set under the ground of the rectifier room of an indoor building, and a natural air inlet 14 is set on the ground with holes or shutters are installed, and a mechanical air outlet 16 is set on the roof of the rectifier room. A local basement 11 is arranged under the ground of the fan 6 of the pure water cooler. The local basement 11 is provided with a drain pipe 18. The drain pipe 18 discharges rainwater into the drainage pit 4 of the voltage regulating rectifier transformer. The depth of the local basement 11 is lower than that of the voltage regulating rectifier transformer. Drainage oil drainage pit 4 depth is shallow. The ground of the pure water cooler fan and the wall of the local basement 11 are left with holes to set t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com