Technology for processing vacuum freeze-dried asparagus instant powder

A processing technology and technology of instant powder, applied in the field of processing technology of vacuum freeze-dried asparagus instant powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] Embodiment 1, a kind of processing technology of vacuum freeze-dried asparagus instant powder, the steps are as follows:

[0093] (1) Raw material selection: choose asparagus waste materials with emerald green color, good plumpness and no rot.

[0094] (2) Thawing: put the waste asparagus into a beaker, and thaw naturally at room temperature for 30 minutes.

[0095] (3) Juicing: the thawed asparagus waste was squeezed with a juicer, and distilled water was added to adjust the concentration to 20%.

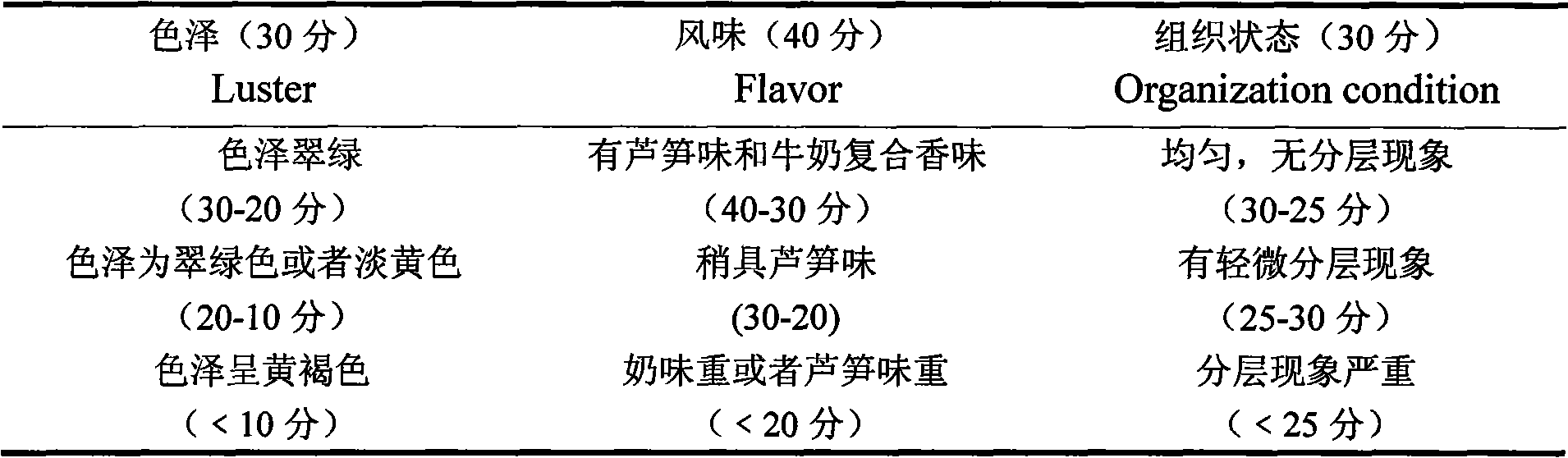

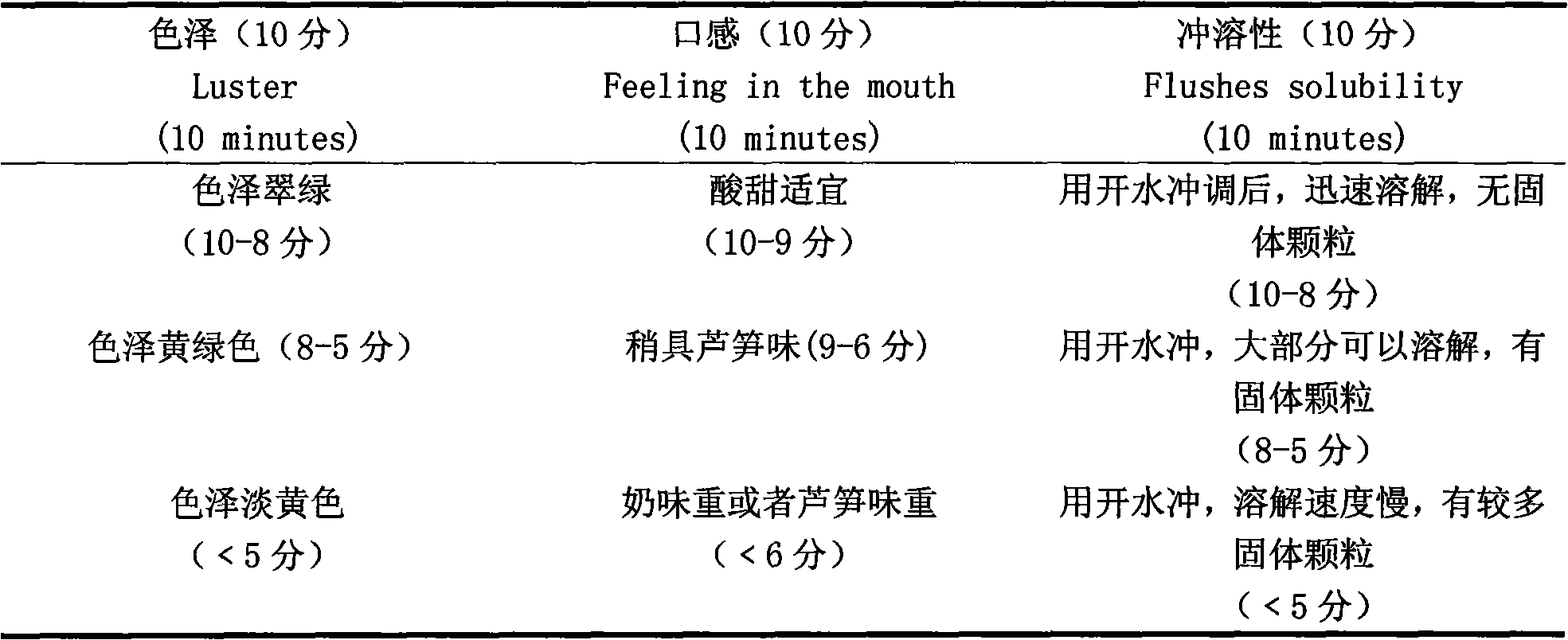

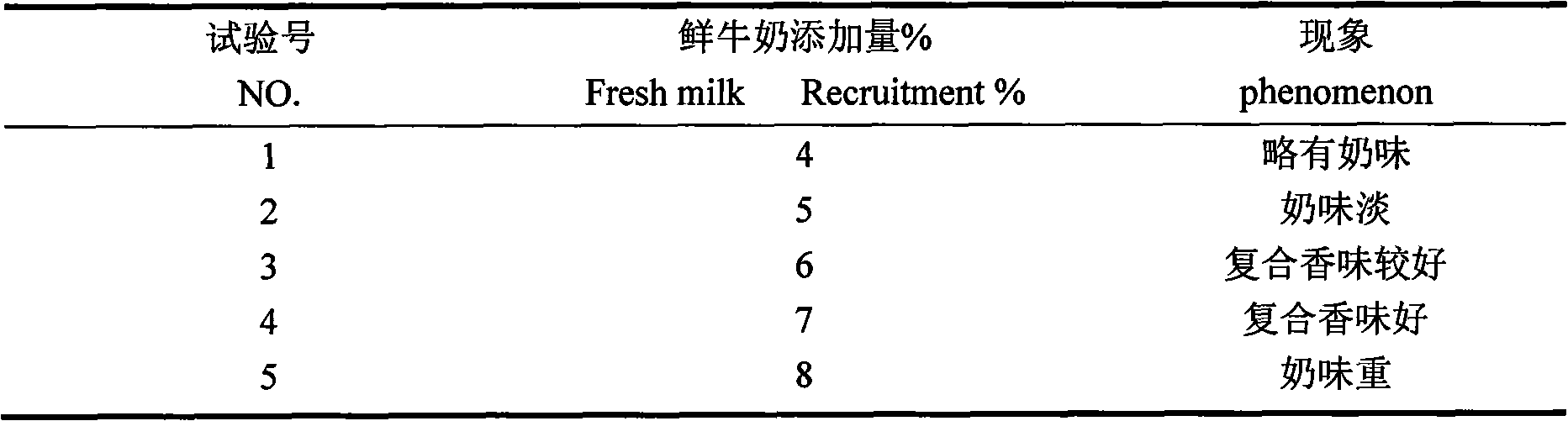

[0096] (4) Preparation: put 6% sucrose by mass and 0.35% citric acid by mass into cold water and stir until uniform, put maltodextrin with 13% by mass in hot water, heat and stir continuously until dissolved, Then, according to the order of 6% fresh milk, sucrose and citric acid respectively by volume, they are added into the asparagus juice in different amounts and stirred evenly.

[0097] (5) Pre-freezing: put the asparagus juice into a freezing tray, spread it flat, and...

Embodiment 2

[0100] Embodiment 2, a kind of processing technology of vacuum freeze-dried asparagus instant powder, the steps are as follows:

[0101] (1) Raw material selection: choose asparagus waste materials with emerald green color, good plumpness and no rot.

[0102] (2) Thawing: put the waste asparagus into a beaker, and thaw naturally at room temperature for 30 minutes.

[0103] (3) Juicing: the thawed asparagus waste was squeezed with a juicer, and distilled water was added to adjust the concentration to 20%.

[0104] (4) Preparation: put 7% sucrose by mass and 0.25% citric acid by mass into cold water and stir until uniform, put maltodextrin with 17% by mass in hot water, heat and stir continuously until dissolved, Then, according to the order of 6.5% fresh milk, sucrose and citric acid respectively by volume, they are added into the asparagus juice in different amounts and stirred evenly.

[0105] (5) Pre-freezing: put the asparagus juice into a freezing tray, spread it flat, a...

Embodiment 3

[0108] Embodiment 3, a kind of processing technology of vacuum freeze-dried asparagus instant powder, the steps are as follows:

[0109] (1) Raw material selection: choose asparagus waste materials with emerald green color, good plumpness and no rot.

[0110] (2) Thawing: put the waste asparagus into a beaker, and thaw naturally at room temperature for 30 minutes.

[0111] (3) Juicing: the thawed asparagus waste was squeezed with a juicer, and distilled water was added to adjust the concentration to 20%.

[0112] (4) Preparation: Put 6.5% sucrose by mass and 0.3% citric acid in cold water and stir until uniform, put maltodextrin with 15% by mass in hot water, heat and stir continuously until dissolved, Then, according to the order of 6% fresh milk, sucrose and citric acid respectively by volume, they are added into the asparagus juice in different amounts and stirred evenly.

[0113] (5) Pre-freezing: put the asparagus juice into a freezing tray, spread it flat, and pre-free...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com