Cobalt crust mining articulated crawler walking device

A crawler traveling device, articulated technology, applied in crawler vehicles, traction connectors, transportation and packaging, etc., can solve problems such as poor mobility, difficult steering of crawler vehicles, complex requirements for cobalt crust mining, etc., to achieve good mobility, The effect of improving adhesion performance and increasing lateral balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

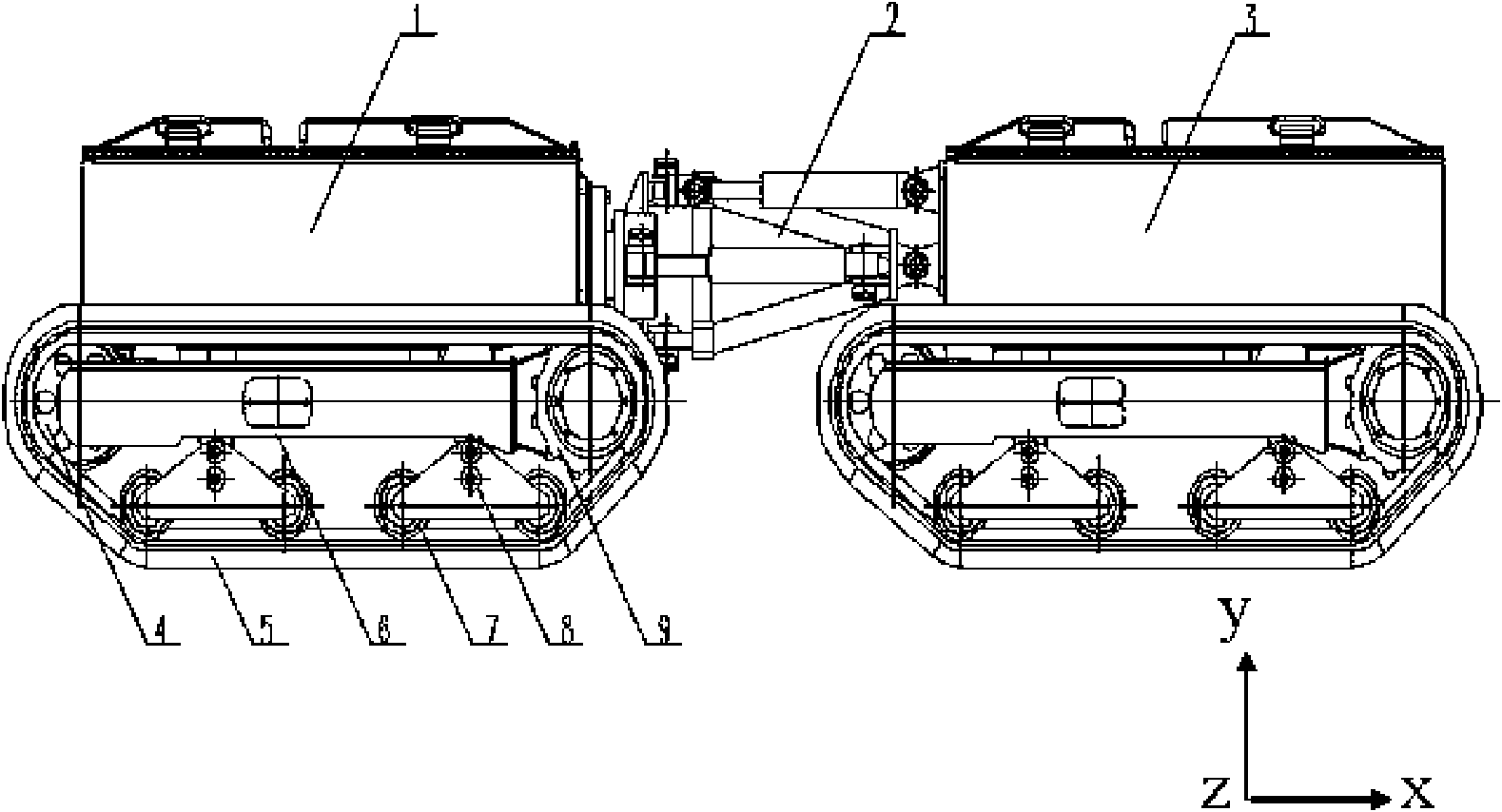

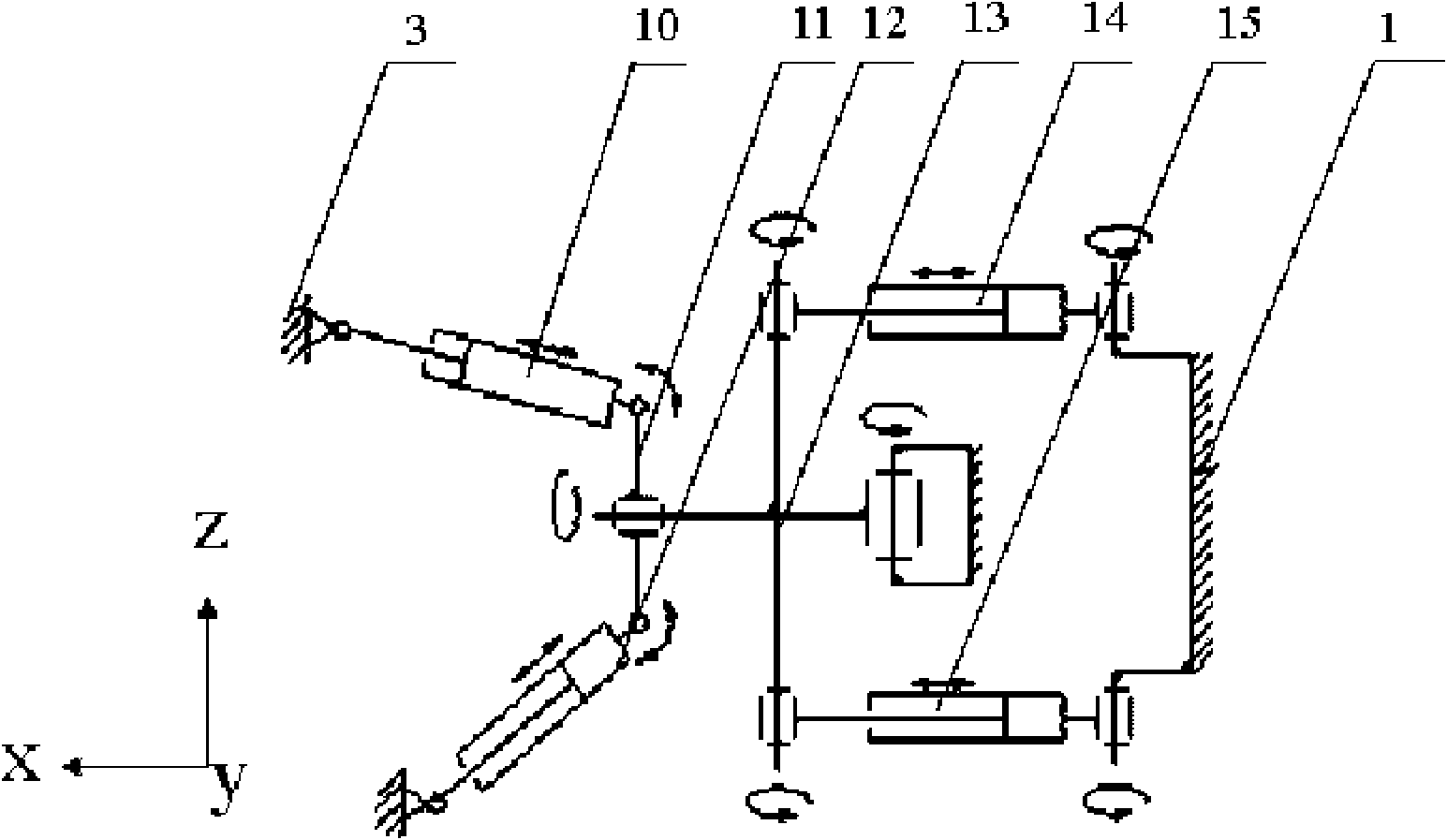

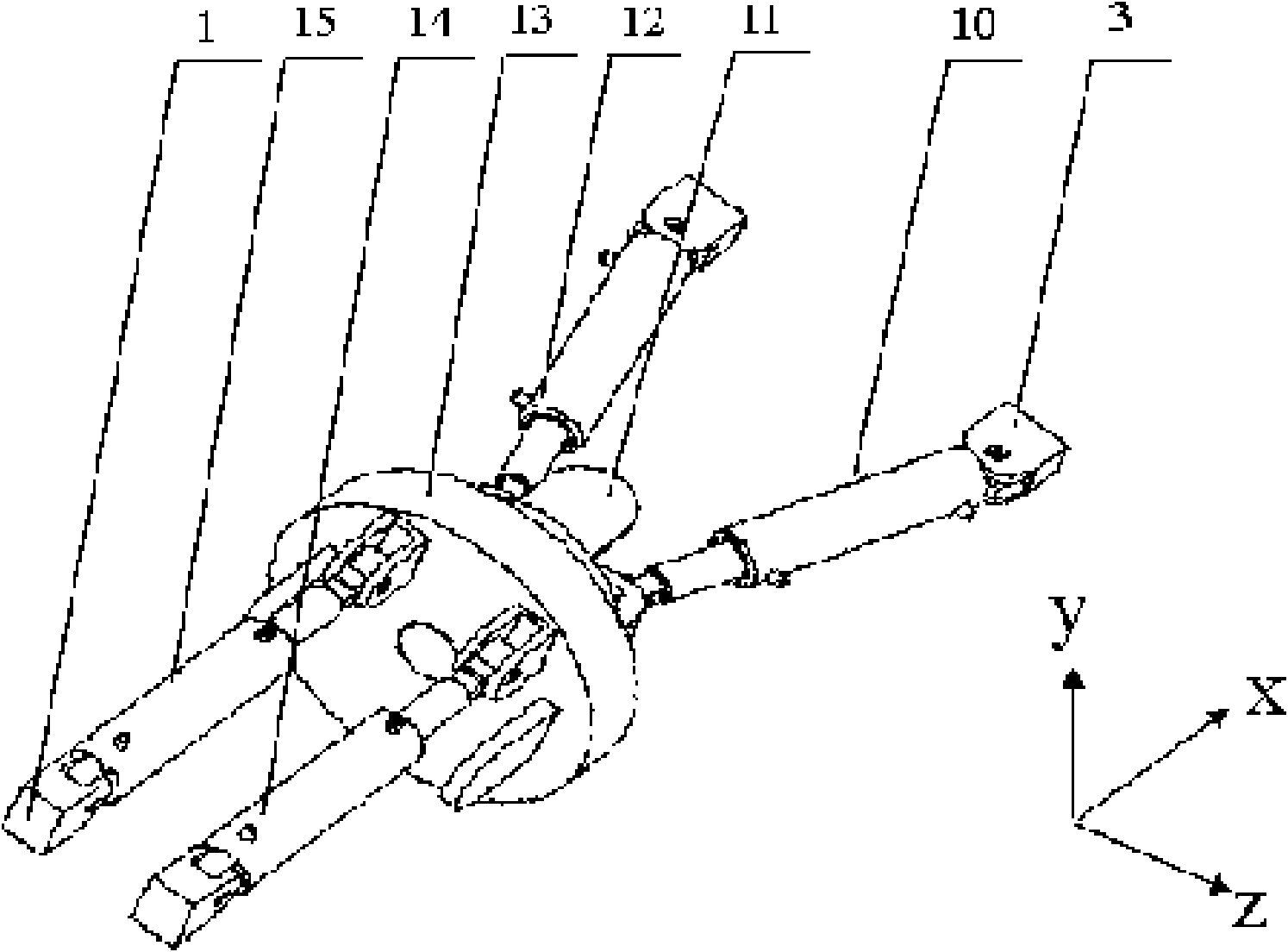

[0016] Such as figure 1 , figure 2 and image 3 As shown, the front crawler vehicle 3 and the rear crawler vehicle 1 are connected by an articulation device 2 with multiple degrees of freedom. The steering movement of the axis and the turning movement around the x-axis, the structure of the hinge device 2 is composed of the first right steering hydraulic cylinder 10 and the first left steering hydraulic cylinder 12, the front disc 11, the rear disc 13, the first right pitch hydraulic cylinder Cylinder 14 and the first left pitching hydraulic cylinder 15 are formed, and the first right steering hydraulic cylinder 10 and the first left steering hydraulic cylinder 12 are respectively hinged with the front tracked vehicle 3 at one end, and the other ends are respectively hinged with the front disc 11, and the front disc 11 Hingedly connected with the rear disc 13, one end of the first right pitching hydraulic cylinder 14 and the first left pitching hydraulic cylinder 15 are res...

Embodiment 2

[0019] Such as figure 1 , Figure 4 and Figure 5 As shown, the front crawler vehicle 3 and the rear crawler vehicle 1 are connected by an articulation device 2 with multiple degrees of freedom. The steering movement of the axis and the turning movement around the x-axis, the hinged device 2 is composed of the second right steering hydraulic cylinder 17 and the second left steering hydraulic cylinder 19, the front support 16, the rear support 18, the second right pitching hydraulic cylinder 20 and the second Two left pitching hydraulic cylinders 21 are formed, one end of the rear bracket 18 is hingedly connected with the front bracket 16, the other end is hinged with the rear crawler vehicle 1, the front bracket 16 is hinged with the front crawler vehicle 3, the second right steering hydraulic cylinder 17 and the second left steering One end of the hydraulic cylinder 19 is hinged with the front bracket 16 respectively, and the other end is hinged with the rear bracket 18 res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com