Process for preparing polysilicon for P-type solar cell

A solar cell and polysilicon technology, applied in the field of smelting, can solve the problems of large hidden dangers in production safety, unstable product quality, and short service life of equipment, and achieve the effects of prolonging the service life of equipment, stable and reliable product quality, and safe production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

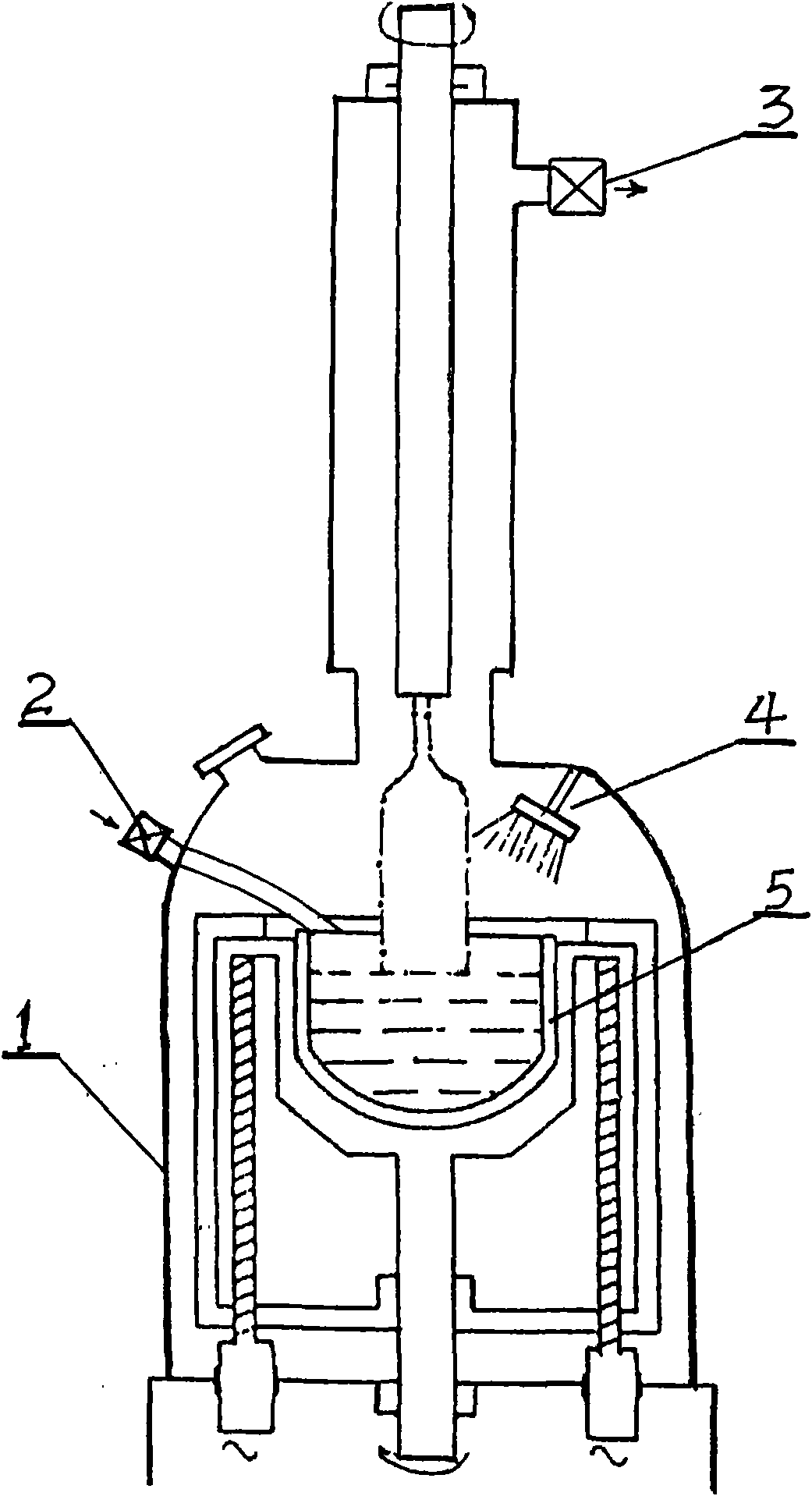

[0023] In conjunction with the accompanying drawings and embodiments, the specific steps of the present invention "a process for producing polysilicon for P-type solar cells" and the specific structure of related equipment are further described.

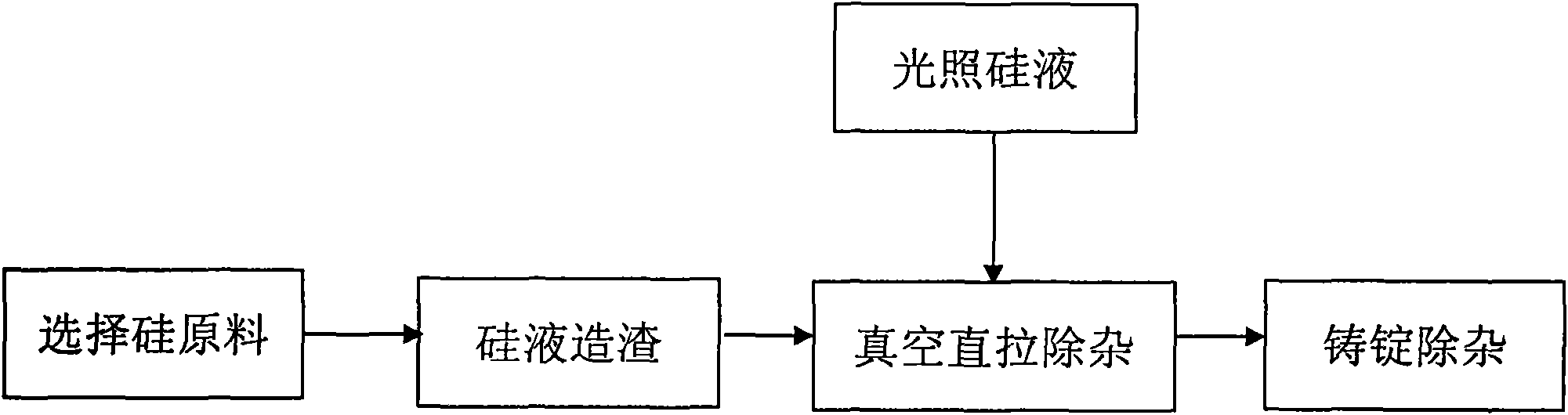

[0024] A kind of embodiment of the technique of producing polysilicon for P-type solar cell of the present invention, see figure 1 , with the following process steps:

[0025] 1. Select silicon raw material. Using metallurgical grade industrial silicon as the raw material, select the metal impurities, phosphorus and boron impurities in the raw materials as the main impurity content limit indicators; metal impurities are limited to within 100PPm, phosphorus and other group V elements are limited to about 10PPm, boron and other group III elements are controlled at Below 1PPm;

[0026] 2. Silicon liquid slagging. The raw materials are fed into the intermediate frequency heating furnace to be melted into silicon liquid, and at least o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com