Mineral powder capable of being heated by microwave in bituminous concrete and application thereof

A technology of asphalt concrete and microwave heating, which is applied in the field of asphalt concrete, can solve the problems of uneven distribution, large amount of coarse aggregate and fine aggregate, and great difficulty, so as to improve controllability, microwave absorption efficiency, and diffusion The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

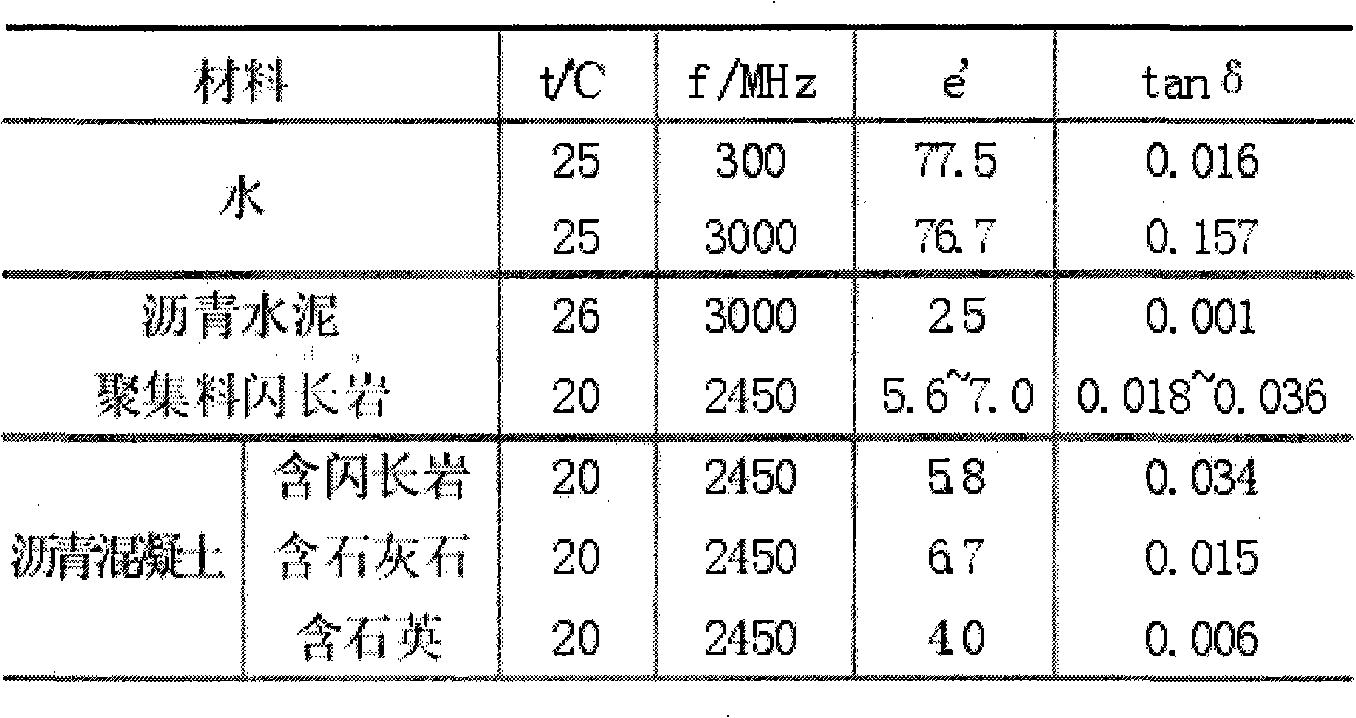

Method used

Image

Examples

Embodiment Construction

[0024] In this example, the asphalt concrete and the amount of asphalt added to the asphalt concrete were combined according to conventional forms, and the asphalt ratio (ie, the specific gravity of asphalt and stone material) was combined according to conventional asphalt concrete. The proportion of aggregated materials is also screened and combined according to conventional methods. For example, by weight, 10-15mm gravel, 5-10mm gravel, 0-5mm stone chips, medium sand, and mineral powder are respectively 27 and 22. , 35, 12, 4.

[0025] The difference from the prior art is that in this embodiment, all or part of the ore powder is replaced by ferrite, and the ferrite accounts for 10% to 100% of the total amount of ore powder by weight percentage.

[0026] In practical application, for the upper layer, middle layer and lower layer on the same road section, increasing the content of ferrite in turn can adjust the distribution of microwave energy in the depth direction of the roa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com