Integrated silt loosening and sucking device for removing silt

A dredging device and sludge technology, which is applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of difficult extraction of hardened mud, high price of equipment, and difficult transportation, and achieve light weight, reasonable and simple overall structure, and easy The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention is described in detail:

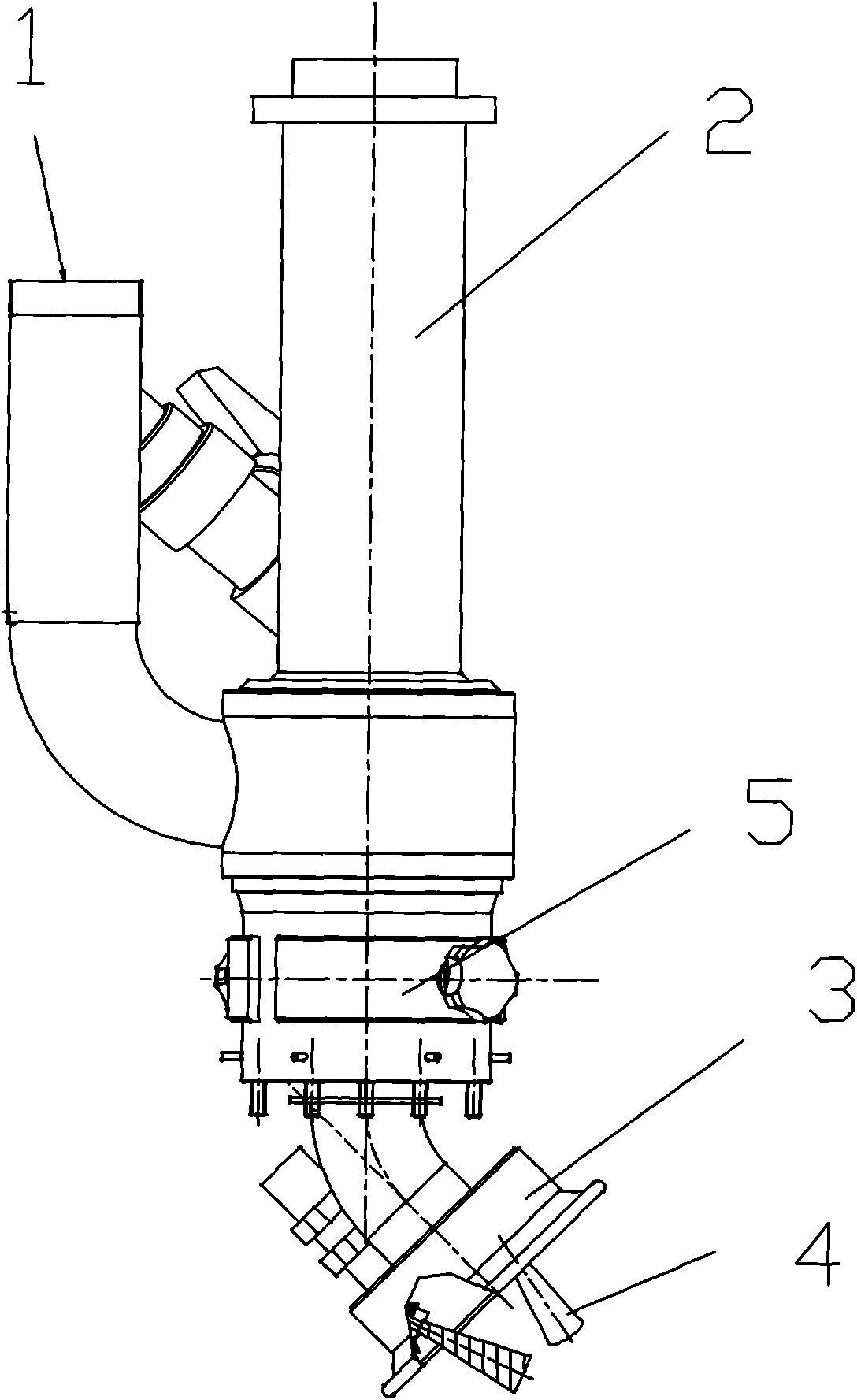

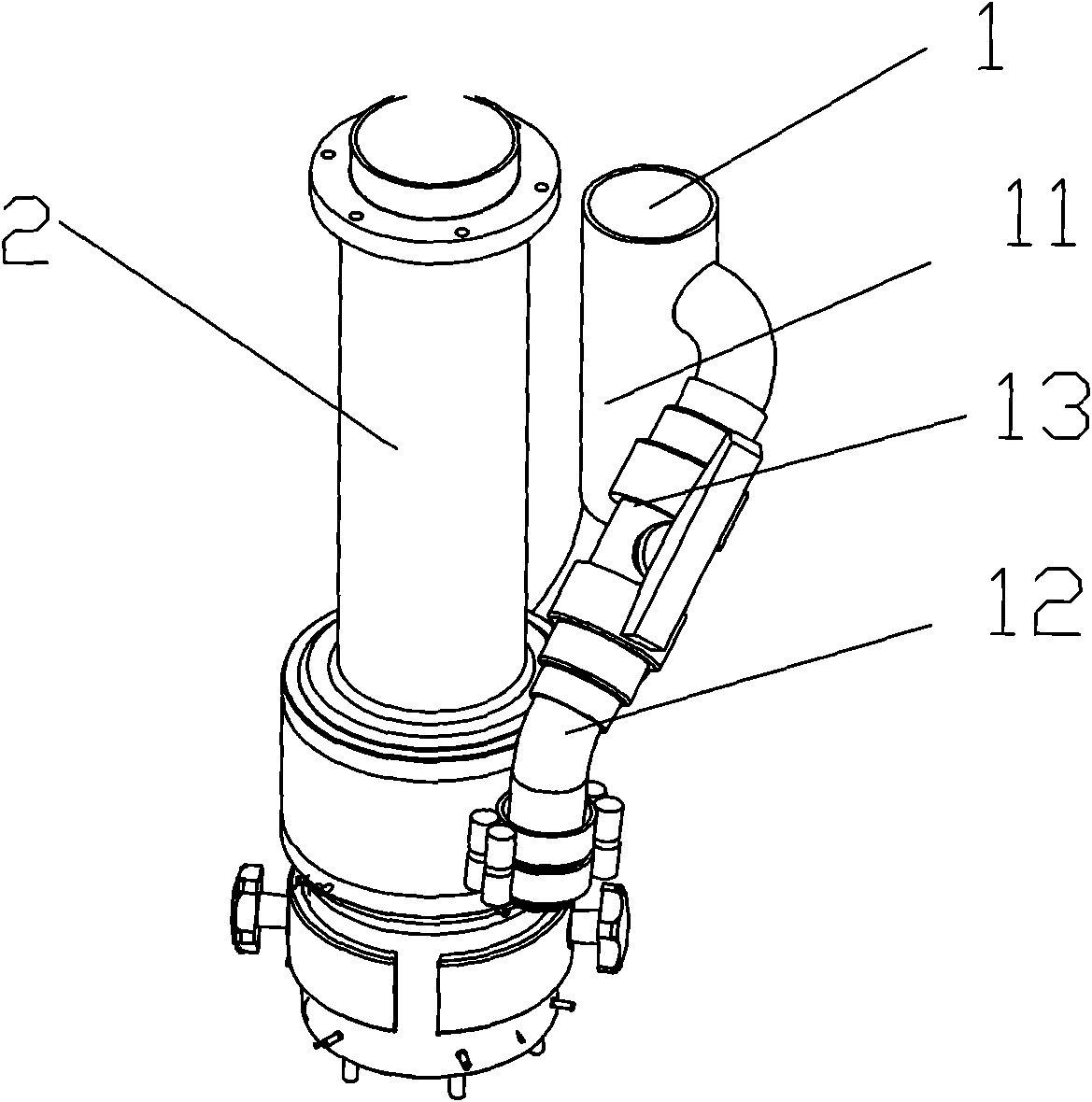

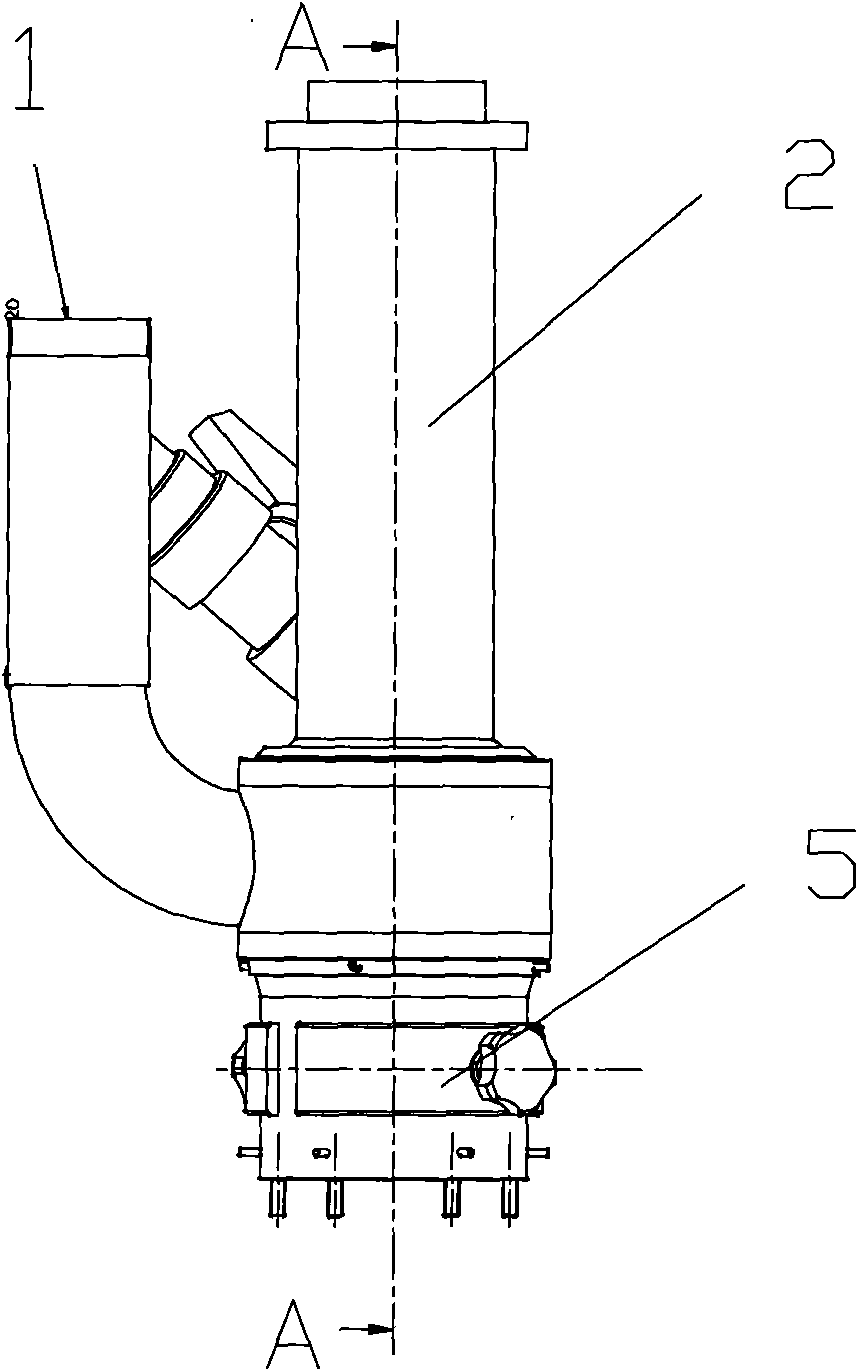

[0025] like figure 1 , figure 2 As shown, the sludge loosening and suction integrated dredging device of the present invention consists of a high-pressure water inlet pipe 1, a high-pressure water nozzle 4, a sludge suction head cover 3, a mud outflow pipe 2, and a negative pressure regulating valve 5. The high-pressure water inlet pipe 1 has two outlets. , one outlet 11 is connected to the high-pressure water nozzle 4 on the mud suction head cover 3, which is used for ejecting the loose and compacted mud of high-pressure water, and the other outlet 12 is connected to the high-pressure water flow channel 21 in the mud outlet pipe 2, and the high-pressure water flow channel The outlet of 21 is consistent with the outflow direction of the mud. When the high-pressure water flows in the reverse direction through the high-pressure water flow channel, a negative pressure cavity 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com