Power supply system

A power supply system and electric energy technology, which is applied in the system, electrical components, fixed capacitor electrodes, etc. for storing electric energy, and can solve the problems of fast discharge speed, easy damage, and aging of batteries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The main feature of the present invention is to provide a power supply system comprising an energy storage device composed of one or more magnetic capacitors. The power supply system can use the large amount of electric energy wasted in known lifting equipment through the high storage capacity of the magnetic capacitors. Recycling and storage of energy capacity to achieve the purpose of saving energy reuse and reducing load electric energy costs.

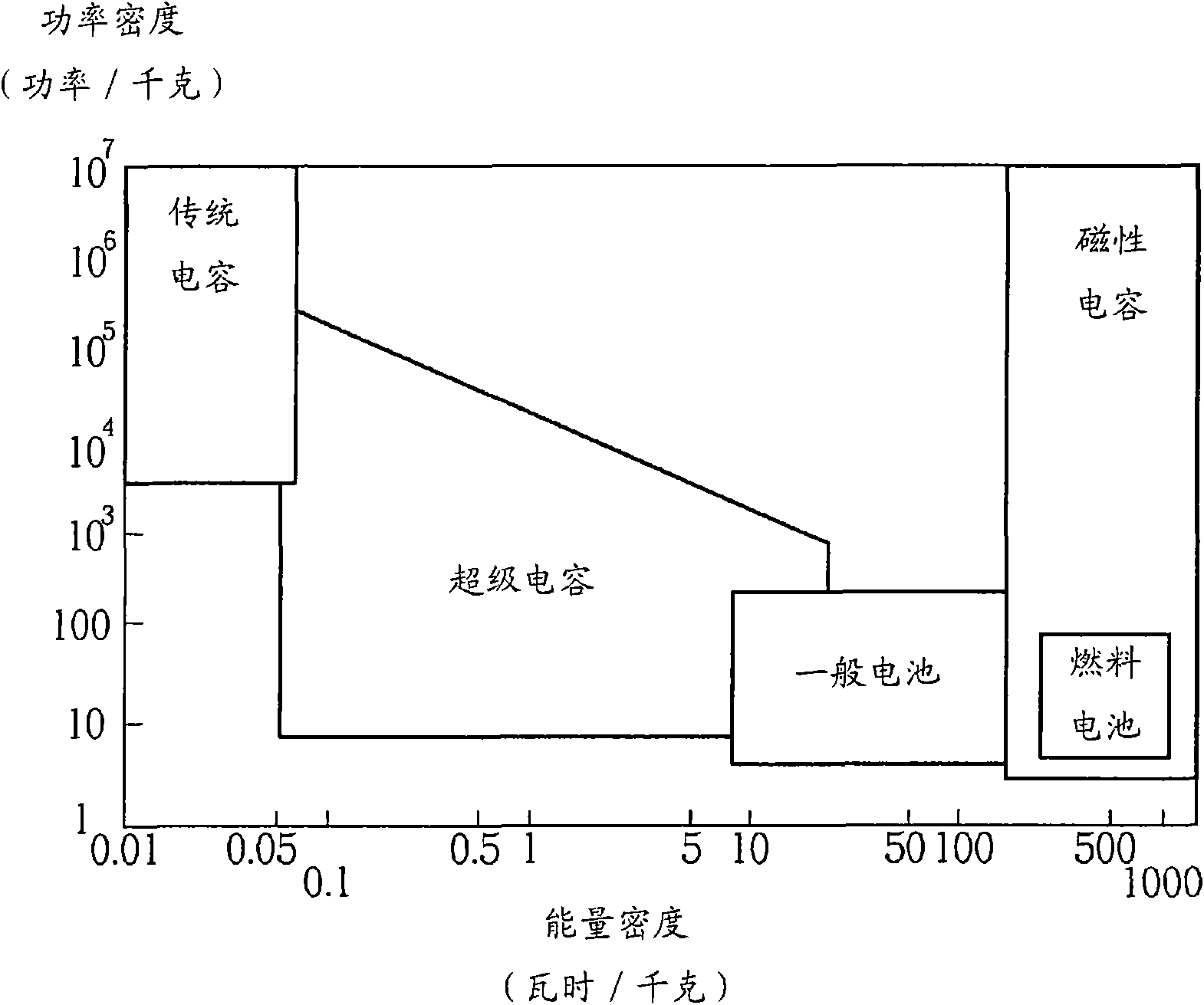

[0046] Compared with traditional electric energy storage devices (such as batteries or capacitors or supercapacitors), the magnetic capacitor disclosed in the present invention can store charges at a higher density through the magnetic field formed at the upper and lower electrodes, so that in lifting equipment , the possibility of recovering energy can be achieved only by paying an additional weight and hardware cost within an acceptable range.

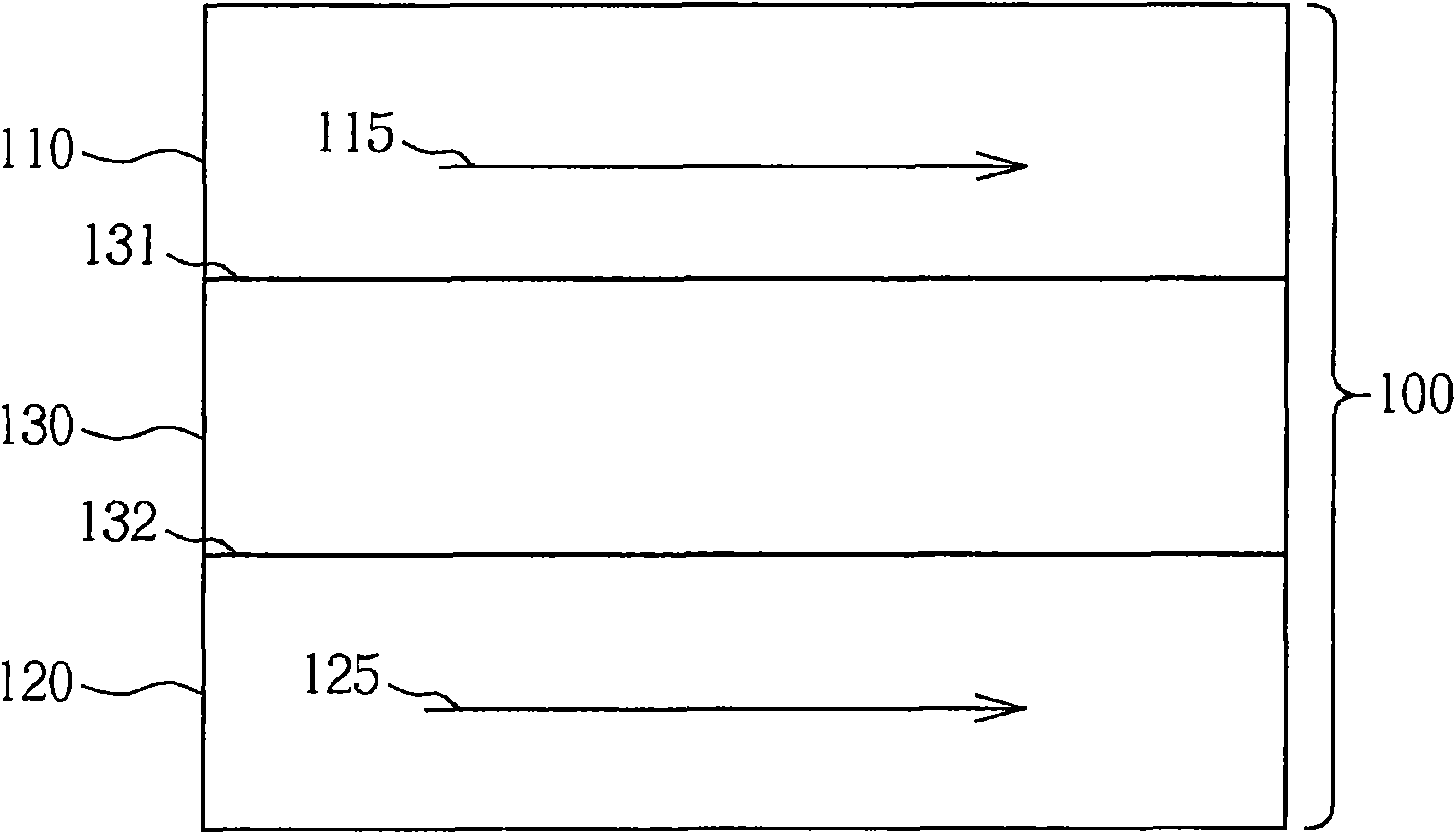

[0047] The principle and operation details of the magnetic capacitor of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com