Quantitative application technology for removing and recovering phosphorus from water body with rich phosphorus or sewage using natural mineral

A natural mineral and water body technology, applied in the field of water pollution control, can solve the problems of high operating cost, phosphorus removal and recycling, retention, etc., and achieve the effect of convenient use and water body optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

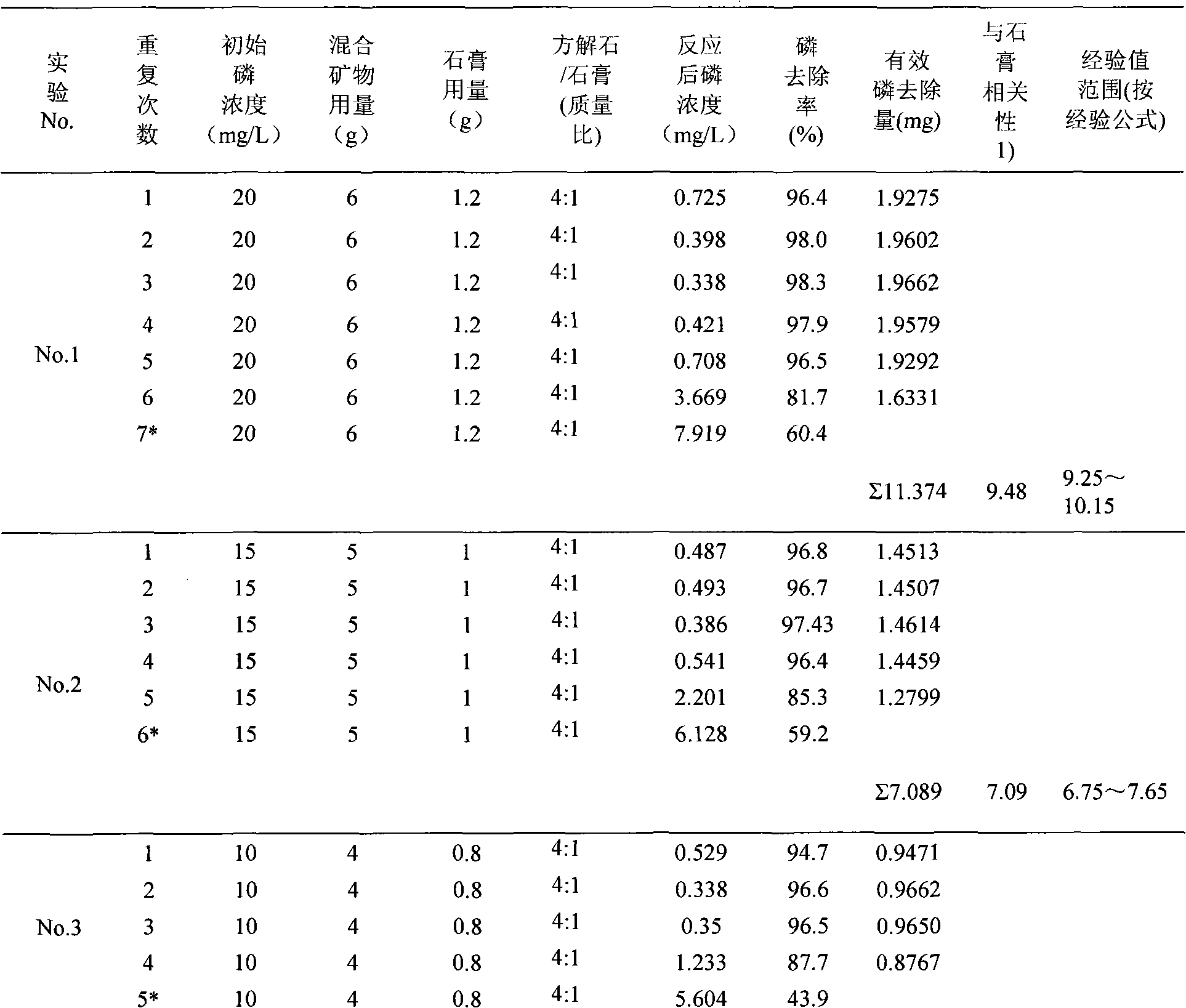

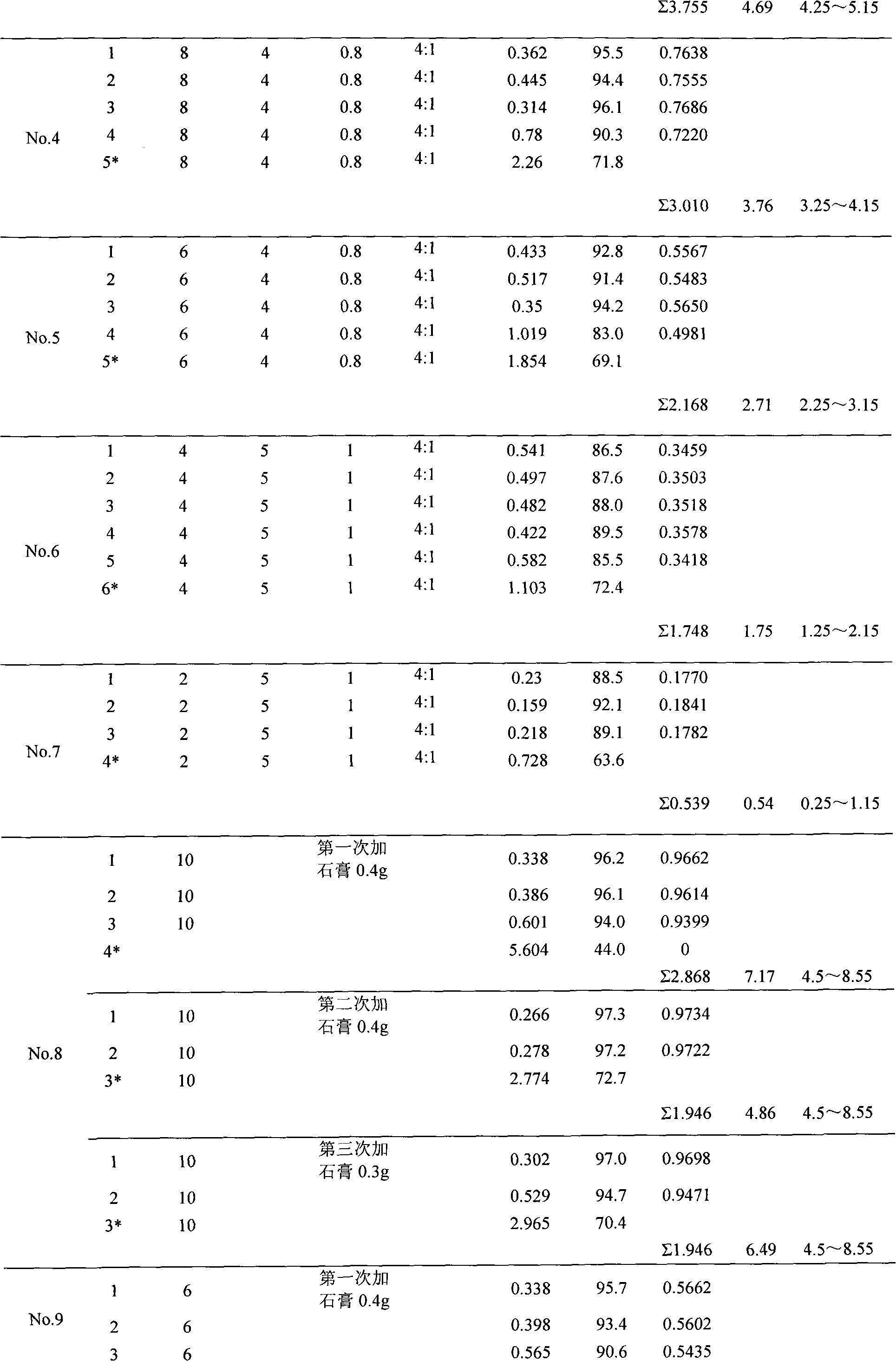

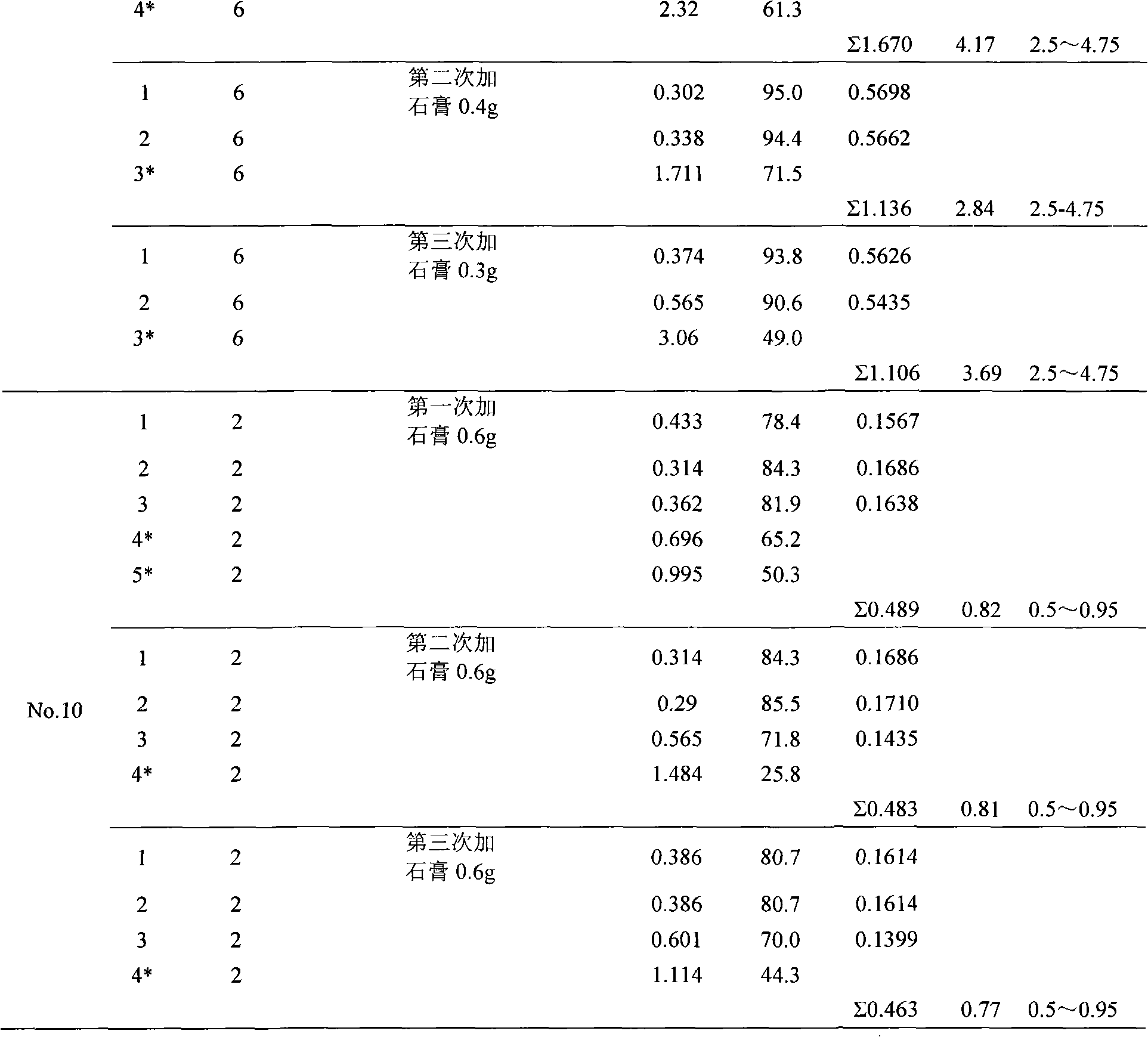

[0029] Take 6g of mixed mineral powder (the particle size of calcite is 325 mesh, and the particle size of gypsum is 500 mesh) with a ratio of 4:1 (mass ratio of calcite / anhydrite), put it into a conical flask with a capacity of 250mL, add The initial phosphorus concentration is 20 mg / L solution, and the pH is adjusted to 7.5; put it into a constant temperature oscillator, set the rotation speed at 150 rpm, and the temperature at 30°C. After reacting for 10 hours, take the supernatant for testing. Then, remove the supernatant in the Erlenmeyer flask (slowly pour it out), dry the residual mixed mineral powder in the Erlenmeyer flask, then add 100 mL of a solution with an initial phosphorus concentration of 20 mg / L, and repeat the experiment under the above conditions , until the effect of phosphorus removal (recovery phosphorus) is low. The final total amount of effective phosphorus removal is 11.374 mg, and the correlation between the total amount of effective phosphorus remov...

Embodiment 2

[0031] Take 5g of mixed mineral powder (the particle size of calcite is 325 mesh, and the particle size of gypsum is 500 mesh) with a ratio of 4:1 (mass ratio of calcite / anhydrite), put it into a conical flask with a capacity of 250mL, add The initial phosphorus concentration is 15 mg / L solution, and the pH is adjusted to 7.5; put it into a constant temperature oscillator, set the rotation speed at 150 rpm, and the temperature at 30°C. After reacting for 10 hours, take the supernatant for testing. Then, remove the supernatant in the Erlenmeyer flask (slowly pour it out), dry the residual mixed mineral powder in the Erlenmeyer flask, then add 100 mL of a solution with an initial phosphorus concentration of 15 mg / L, and repeat the experiment under the above conditions , until the effect of phosphorus removal (recovery phosphorus) is low. The final total amount of effective phosphorus removal is 7.089 mg, and the correlation between the total amount of effective phosphorus remova...

Embodiment 3

[0033] Take 4g of mixed mineral powder (the particle size of calcite is 325 mesh, and the particle size of gypsum is 500 mesh) with a ratio of 4:1 (mass ratio of calcite / anhydrite), put it into a conical flask with a capacity of 250mL, add The initial phosphorus concentration is 10 mg / L solution, and the pH is adjusted to 7.5; put it into a constant temperature oscillator, set the rotation speed at 150 rpm, and the temperature at 30°C. After reacting for 10 hours, take the supernatant for testing. Then, remove the supernatant in the Erlenmeyer flask (slowly pour it out), dry the residual mixed mineral powder in the Erlenmeyer flask, then add 100 mL of a solution with an initial phosphorus concentration of 10 mg / L, and repeat the experiment under the above conditions , until the effect of phosphorus removal (recovery phosphorus) is low. The final total amount of effective phosphorus removal is 3.755 mg, and the correlation between the total amount of effective phosphorus remova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com