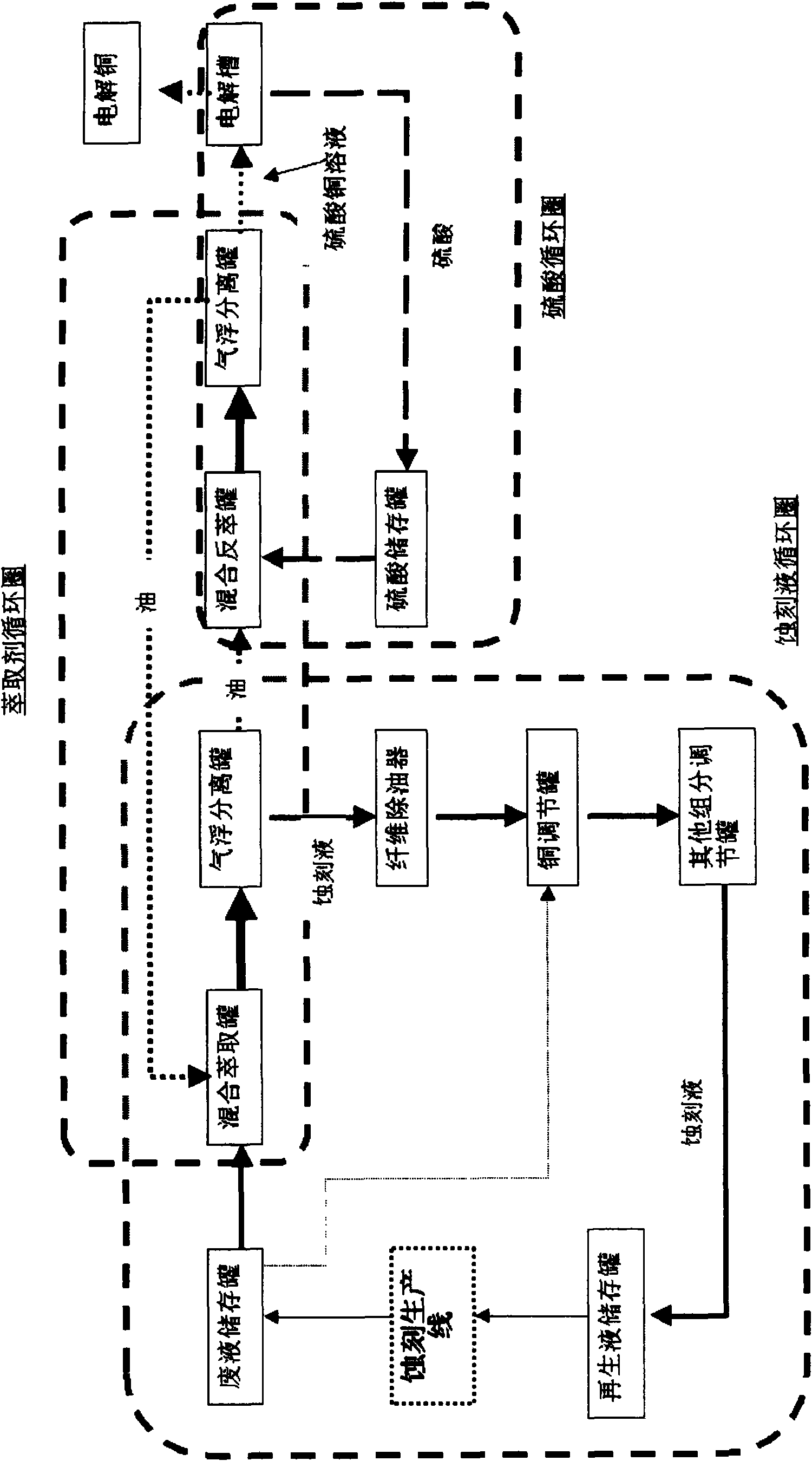

Fully closed system for regenerating alkaline etching liquid and recovering copper in PCB

A recovery system and alkali etching technology, applied in the field of regeneration system, can solve the problems of reducing the etching line speed and quality, the etching solution must be completely replaced, and the impact of etching solution regeneration and reuse, so as to save costs, speed and operating costs saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

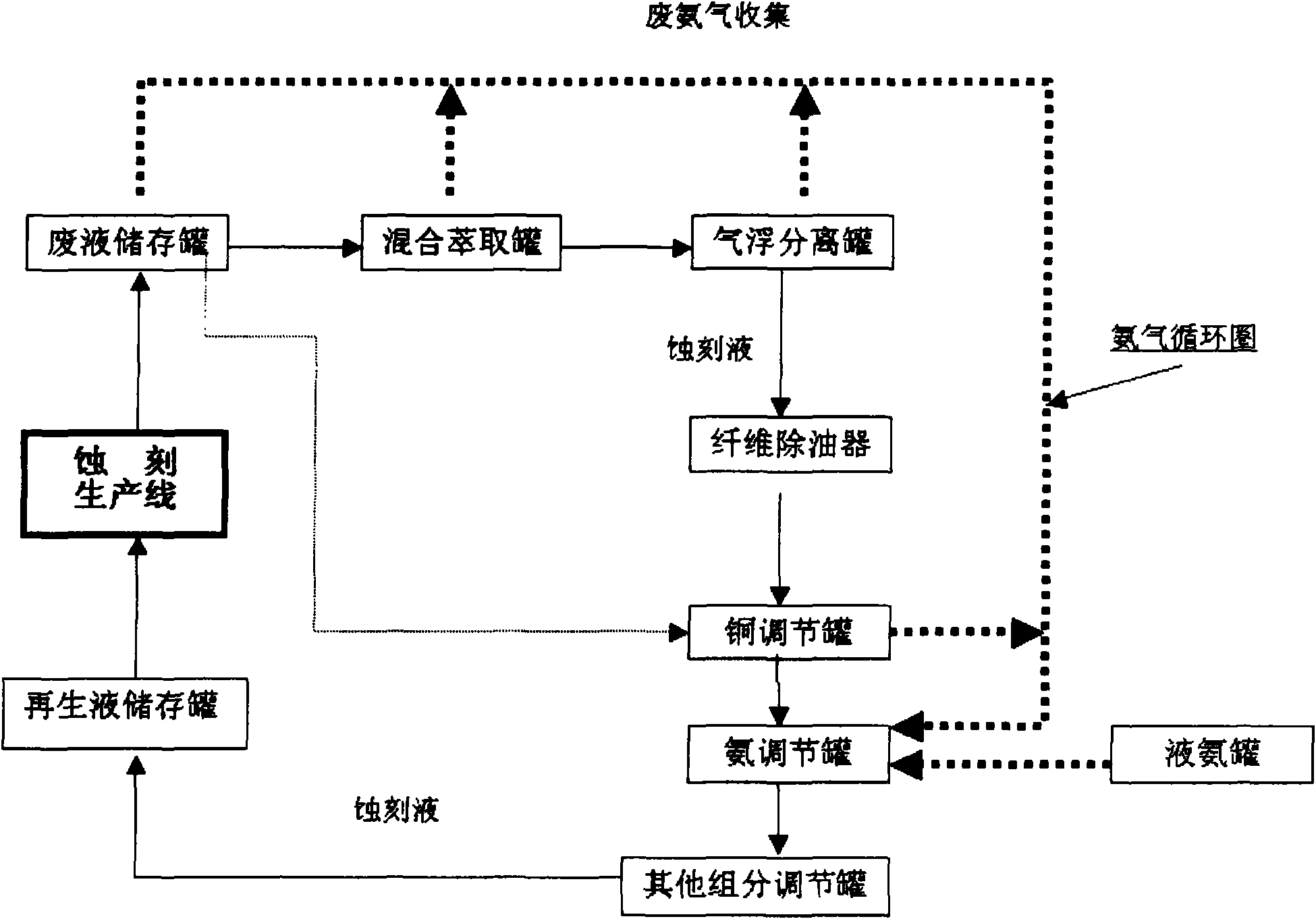

Embodiment Construction

[0022] In a case, the amount of etching waste liquid from the alkaline etching production line is 3M 3 / Day, which is 90M 3 / Month, Cu 2+ The concentration is 140-150g / L, and it is stored in a waste liquid tank. The waste liquid is pumped into the extraction pool through a pump, and the injection volume is 125L / h. With a volume of 125L, it adopts mechanical stirring and continuous operation, in and out at the same time, and the extraction time is 1h. The overflowing mixed liquid is separated in a gravity tank, the volume of the gravity separation tank is 250L, and it is made of plexiglass. A microporous aeration head is installed in the separation tank, and the extractant with a small specific gravity enters the stripping mixing tank from above, and the specific gravity The larger etching solution enters the fiber degreaser, and the concentration of copper ions in the separated etching solution is 70g / L.

[0023] The separated etchant is introduced into the original high Cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com