Method for simultaneously producing glutathione and S-adenosyl methionine at high yield

A technology of adenosylmethionine and glutathione, which can be applied in the field of bioengineering and can solve problems such as low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

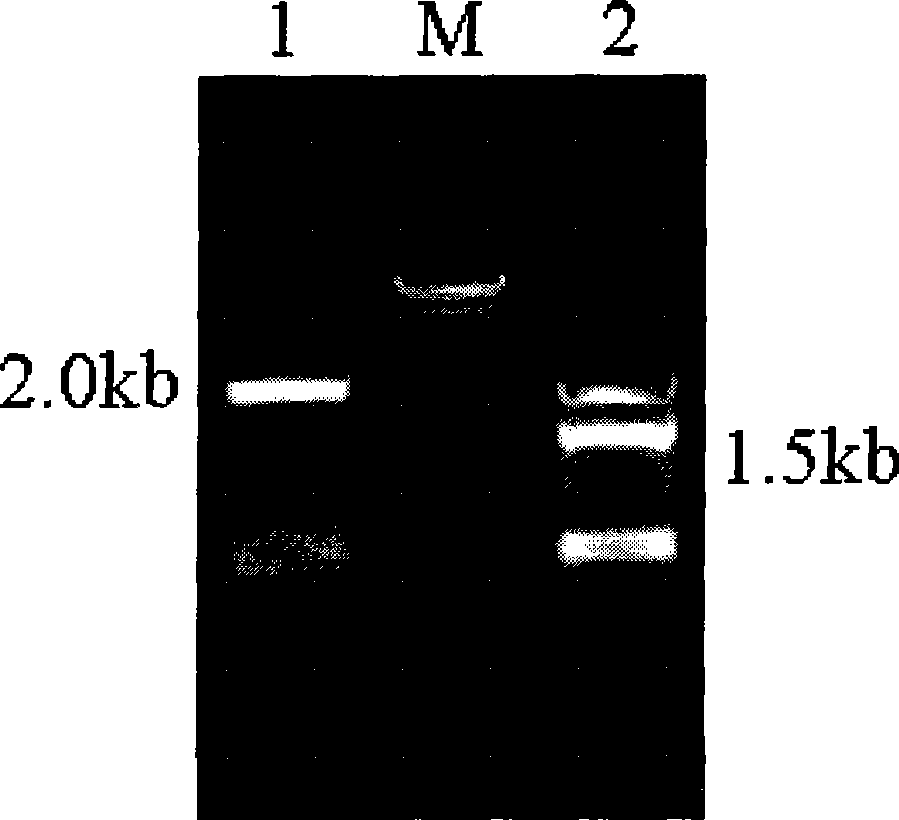

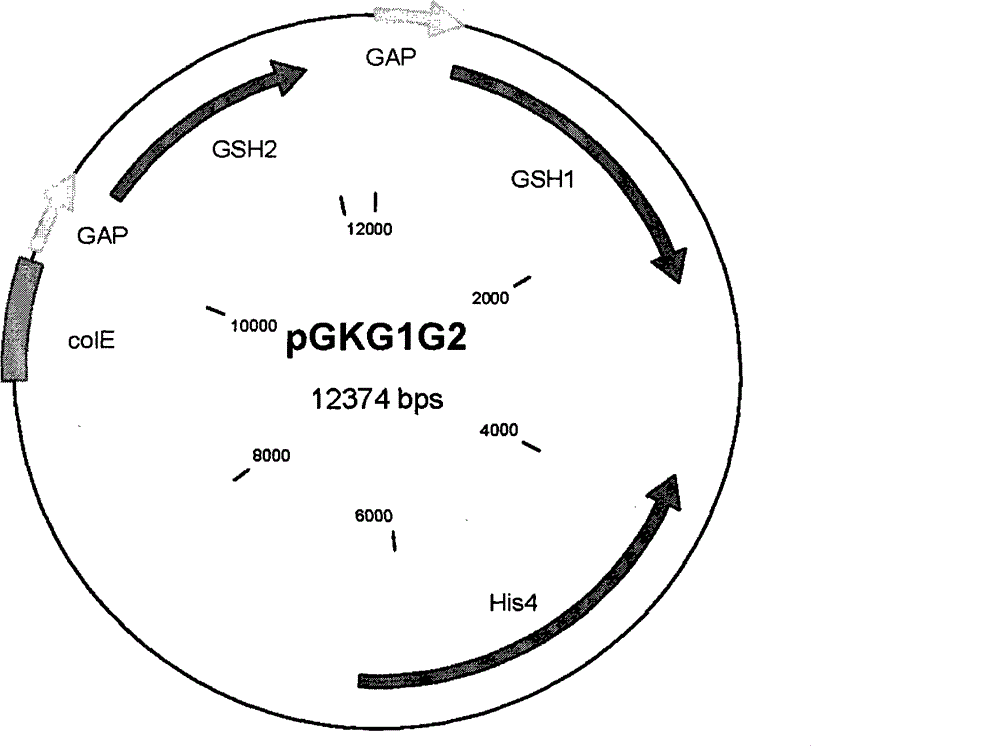

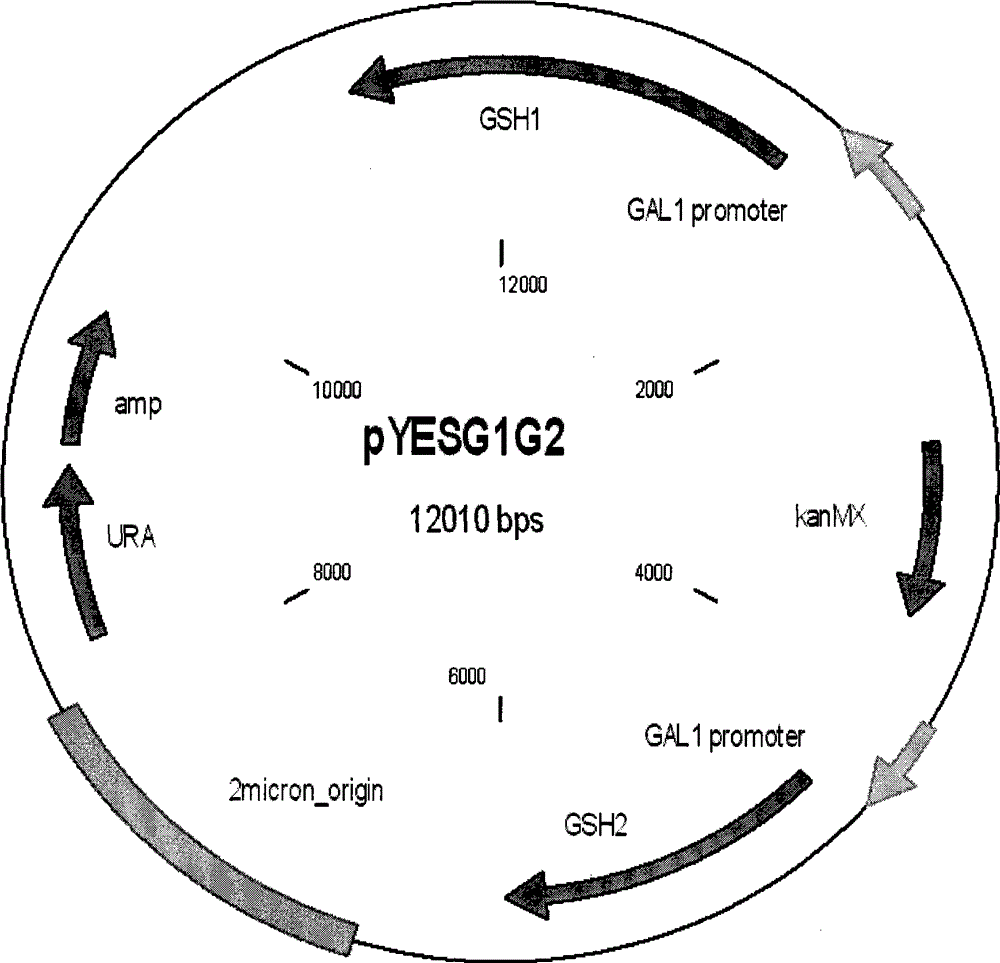

[0044] Example 1 , Construction of a strain co-expressing glutathione synthetase and SAM synthetase

[0045] In this example, the plasmids for expressing glutathione synthase and SAM synthetase for Pichia pastoris or Saccharomyces cerevisiae were constructed respectively, and then the constructed plasmids were transformed into corresponding Pichia In yeast or Saccharomyces cerevisiae, a strain capable of co-expressing glutathione synthetase and SAM synthetase can be constructed in Pichia pastoris and Saccharomyces cerevisiae.

[0046] 1.1, GSH1, GSH2, SAM fragment amplification

[0047] In this embodiment, the primers for amplification are first designed, the genome as the amplification template is extracted, and then fragments of GSH1, GSH2 and SAM synthetase 2 are obtained by PCR respectively, as follows:

[0048] According to the GSH1 and GSH2 sequences reported by Genebank (EF633694, EF633695), the following 4 primers were designed to clone the GSH1 and GSH2 sequences:

[0049] GS...

Embodiment 2

[0139] Example 2 , HZ111 fermentation simultaneously or separately to produce glutathione and S-adenosylmethionine

[0140] Select a single colony of HZ111 grown for three days to inoculate 30ml of YPD medium, culture at 30℃, 240rpm for 20h, then insert 320ml of YPD medium, culture at 30℃, 240rpm for about 8h, insert 3.15L of fermentation medium BMGY (7.5L fermenter), add a final concentration of 0.01% defoamer (polyoxypropylene polyoxyethylene glyceryl ether, that is, foam enemy), carry out fermentation, control the temperature at 30 ℃, and add glycerin during the fermentation process to meet cell growth If necessary, the pH is controlled at 6.0 by adding ammonia. When the fermentation reaches 30h, add a total of 30g of L-cysteine and a total of 30g of L-methionine, continue the fermentation, and perform a test at 70h. The test results show that the glutathion is in the fermentation broth. The content of glycosyl is 3.0g / L, and the content of S-adenosylmethionine is 3.5g / L. ...

Embodiment 3

[0142] Example 3 , HZ203 fermentation simultaneously or separately to produce glutathione and S-adenosylmethionine

[0143] The formula of the medium used in this example is as follows (g / L):

[0144] Galactose 40, Yeast Extract 20, Peptone 40, Ammonium Sulfate 2.0, Urea 2.0, KH 2 PO 4 1.5, MgSO 4 ·7H 2 O0.5, ZnSO 4 ·7H 2 O 4 .0×10 -3 , FeSO 4 ·7H 2 O3.0×10 -3 , MnCl 2 ·4H 2 O0.3×10 -3 , CuSO 4 ·5H 2 O0.5×10 -3 , CaCl 2 ·2H 2 O1.0×10 -3 .

[0145] Pick a single colony of HZ203 that has grown for two days and inoculate it into 30ml of the above medium, culture at 30℃ and 240rpm for 20h, then insert 320ml of the above medium, 30℃, 240rpm for about 6h, insert 3.15L of the above fermentation culture In the base (7.5L fermenter), add the final concentration of 0.01% defoamer foam enemy, and carry out fermentation. The temperature is controlled at 30℃. During the fermentation process, galactose is added to meet the needs of cell growth. Ammonia is added and pH is controlled. In 6.0. Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com