Distortion tester

A tester and the same technology, applied in the field of optical systems, can solve problems such as high requirements for the working band of the system under test, time-consuming and labor-intensive test data recording, time-consuming and labor-intensive installation and adjustment work, etc., to improve measurement accuracy and efficiency, repeat measurement Effects of improved precision and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

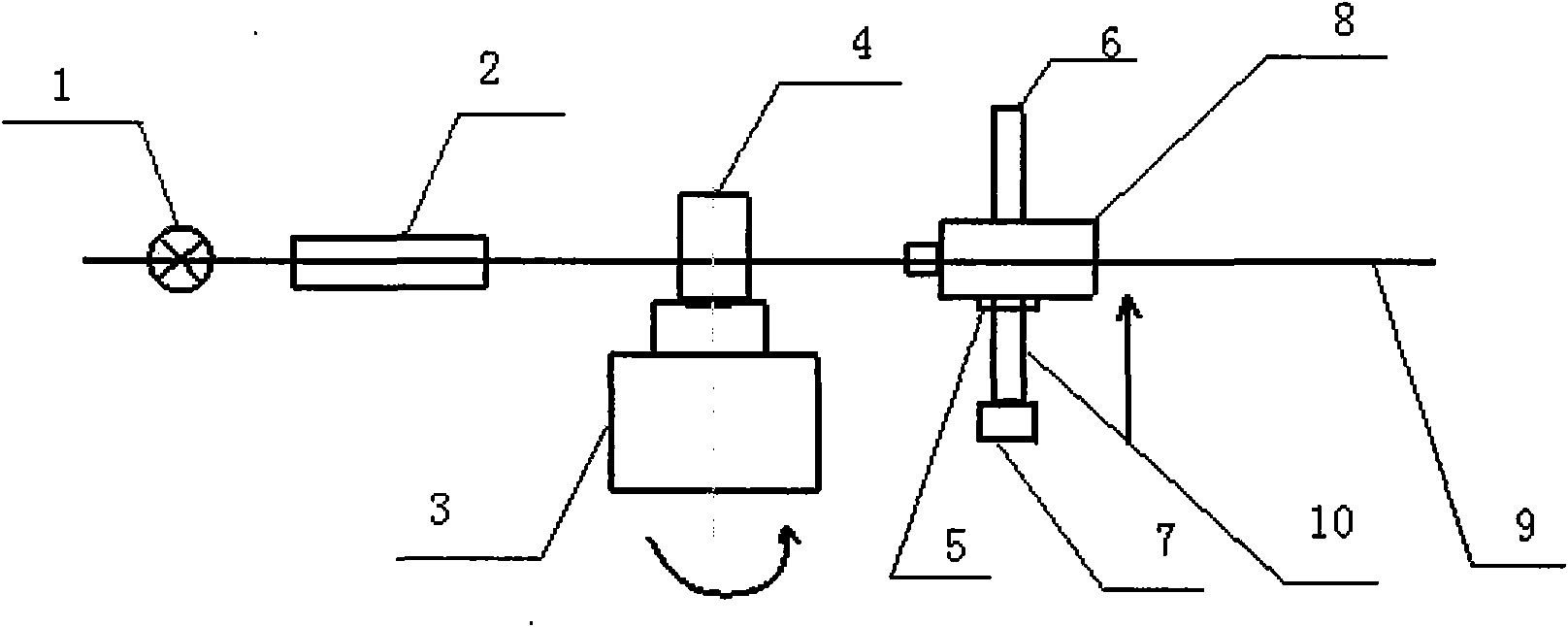

[0027] see figure 2 , the present invention provides a distortion tester, including a turntable 3, and the tester also includes a light source 1, a collimator 2, and a microscopic imaging system 8; the light source 1, the collimator 2, and the microscopic imaging system 8 are arranged on the same optical axis 9.

[0028] The high-precision distortion tester also includes a length measuring device 10 on which the microscopic imaging system 8 is fixed. The length measuring device 10 includes a laser interferometer 7, a reflector 5 and a two-dimensional precision guide rail 6; the reflector 5 is fixed on the lateral guide rail side of the two-dimensional guide rail 6; the normal line of the reflector 5 is perpendicular to the optical axis 9; The laser interferometer 7 emits beams perpendicular to the mirror 5 ; the laser interferometer 7 and the two-dimensional guide rail 6 are fixed on the length measuring device 10 . The two-dimensional precision guide rail 6 can also be an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com