Pharmaceutical formulations

A preparation and active agent technology, applied in the field of pharmaceutical preparations, can solve the problems affecting the robustness of preparations and the impact of preparation robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Tablet preparation:

[0096] Add the ingredients in the granule to the granulator (or mixer), dry mix, then gradually add an appropriate amount of water to the granulator, and granulate until the best granules are obtained. The granules are then wet aggregated for an additional period, if necessary, before being dried in an oven or fluid bed dryer. The dried granules were processed using a fitzmill or manually sieved using a sieve. Sift the silica and HPC Exf through a 40 mesh screen. The ground granules, sieved silica and HPC were charged into a V-blender and mixed at -26 rpm for 5 minutes. Sieve the SSF through a 40-mesh sieve. The screened SSF was added to the mixer and mixed for an additional 5 minutes. The granules were weighed and compressed into tablets using a rounder tooling with a target weight of 275 mg / tablet. The target sheet hardness is -20 SCU.

Embodiment 2

[0098] Solubility determination:

[0099] The solubility value of fenofibrate salt in water was determined at 25°C. These salts were weighed, placed in glass vials, and water was added. In a 25 °C water bath, swirl the suspension head to tail for about 2 days. Measure the pH of the suspension. Residual solids were then removed by filtration through a 0.45 μm PTFE membrane filter. The resulting saturated solution was suitably diluted into the HPLC mobile phase and analyzed by the HPLC assay described below (Table 3). At the end of the experiment, the powder x-ray diffraction pattern of the collected residual solid was recorded.

[0100] HPLC analysis:

[0101] table 3

[0102] HPLC Analysis of Fenofibric Acid

[0103]

[0104]

Embodiment 3

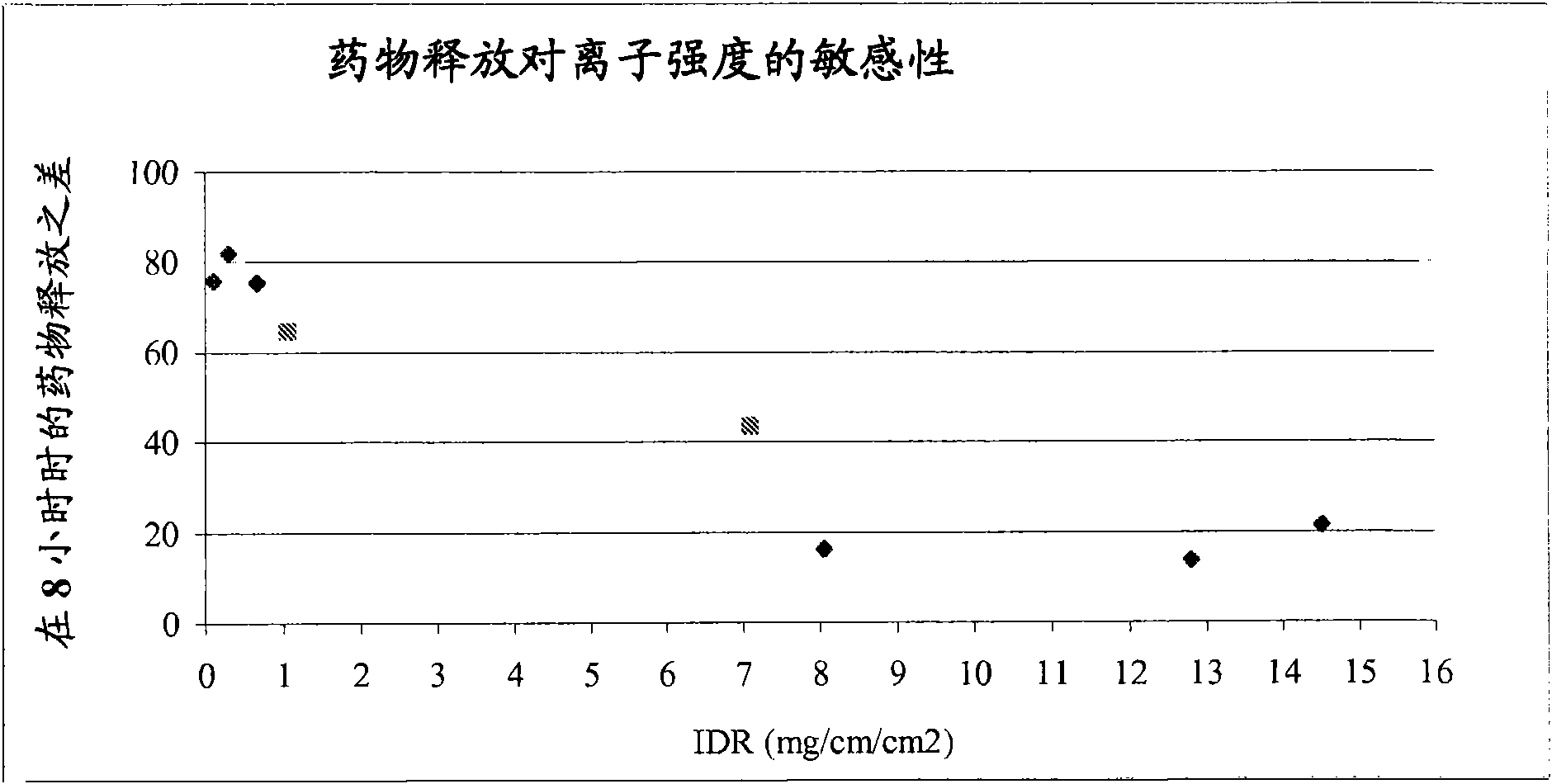

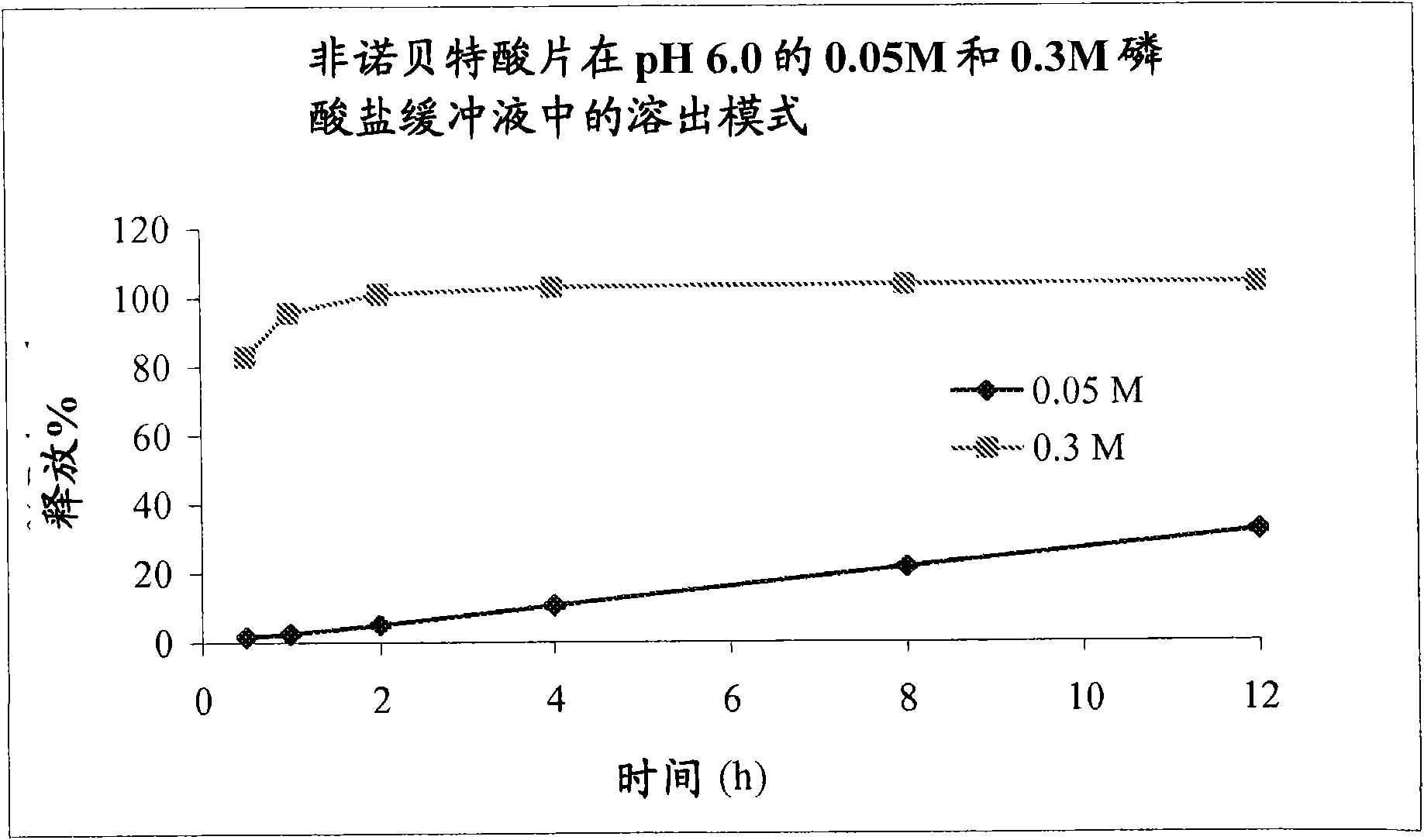

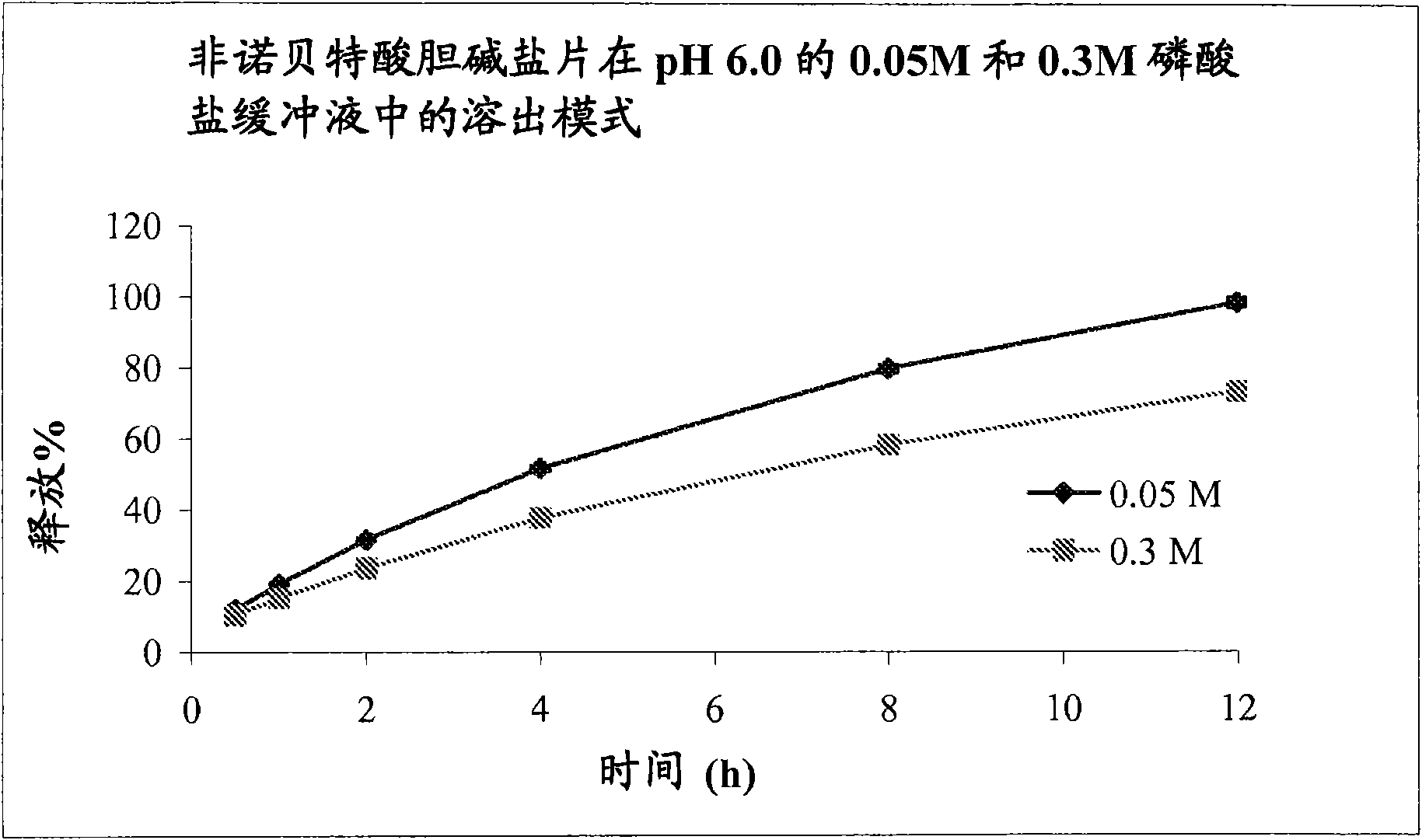

[0106] Intrinsic Dissolution Rate (IDR):

[0107] The IDR of fenofibrate salt was determined in 50 mM sodium citrate buffer, pH 4.0 or pH 6.8 (NaCl, μ = 0.155M).

[0108] Small tablets of these salts were prepared by compressing approximately 100 mg of the compound in a stainless steel mold at 1300 lbs force with a residence time of 1 minute. The mold containing the tablet was submerged in 400 mL of dissolution medium at 37°C. The solution was stirred with a paddle at -60 rpm. At each time point, 3 mL samples were taken and filtered. The first half of the filtrate was discarded and the residue collected and assayed by the HPLC method described above. The total volume of dissolution medium was kept constant by replenishing lost volume at each data point with fresh buffer at 37°C.

[0109] Table 4

[0110] Salt

(mg / ml)

IDR *

at 8 hours

% of 0.05M

at 8 hours

% of 0.3M

in 8 hours

C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solubility | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com