Method for manufacturing cement-based light bricks

A manufacturing method and technology for lightweight bricks, which are applied in the field of lightweight brick manufacturing, can solve the problems of reduced building firmness, reduced earthquake resistance, and deteriorated overall performance, so as to improve apparent hardness and compressive strength, improve Energy-saving effect and strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

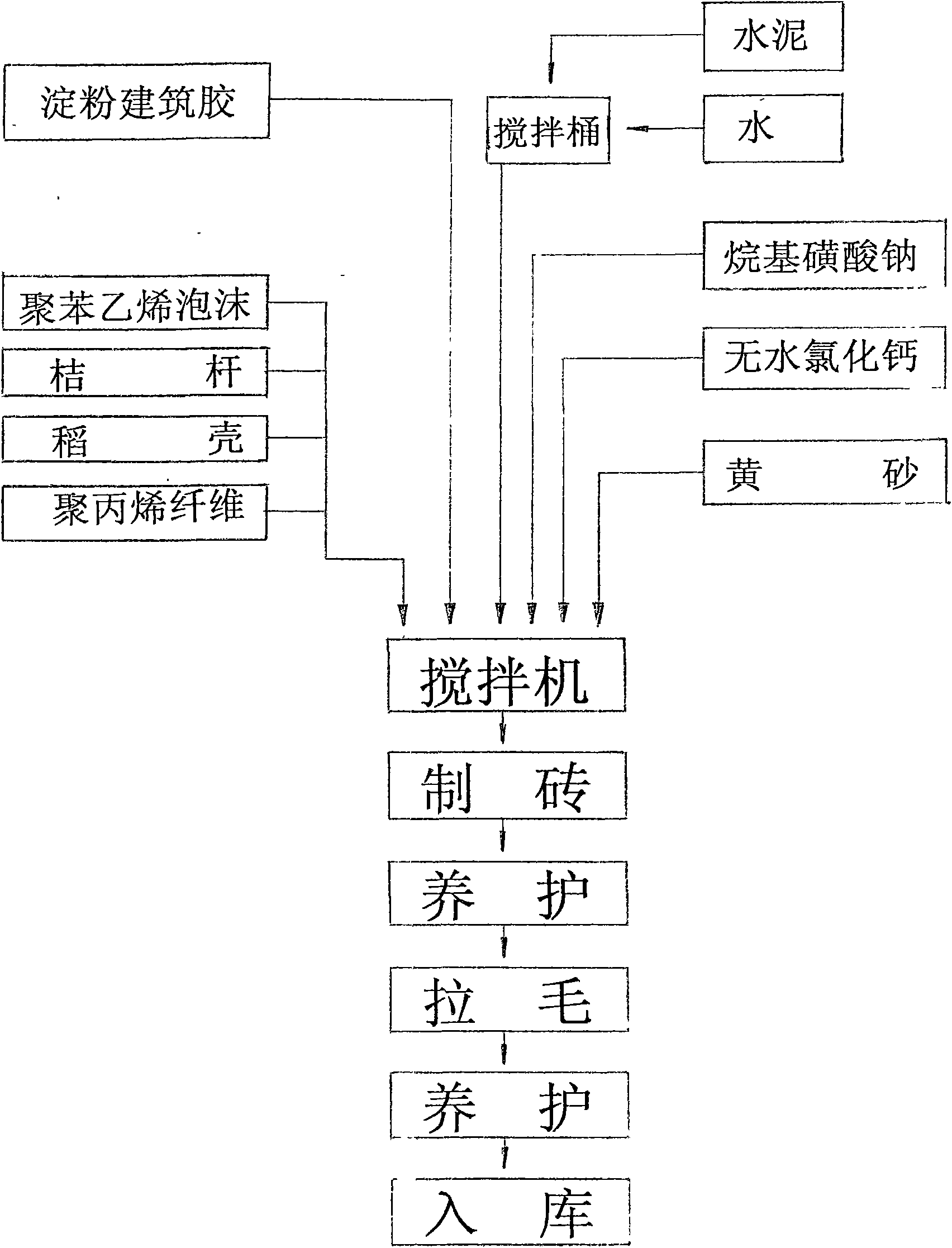

[0009] The manufacturing method of a cement-based lightweight brick of the present invention can be further illustrated by the following drawings and examples.

[0010] As shown in the figure, the present embodiment introduces a manufacturing method of a cement-based lightweight brick made of polystyrene foam, orange stalk, rice husk, polypropylene fiber, starch construction glue, cement, water, sodium alkylsulfonate, Anhydrous calcium chloride and yellow sand are put into the mixer in order to stir and press.

[0011] The formula of a kind of cement-based lightweight brick of the present invention is: 6% polystyrene foam, 15% straw, 25% rice husk, 0.5% polypropylene fiber, 5% starch building glue, 26% cement, 16% water, 2% sodium alkylsulfonate, 1% anhydrous calcium chloride, 4.5% yellow sand.

[0012] The manufacturing method of a kind of cement-based lightweight brick of the present invention is: first put 26% cement, 16% water into the mixing tank, stir for 2-3 minutes, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com