Motor drive system and its control method

一种电机驱动系统、电机电流的技术,应用在电动机控制、电动发电机控制、交流电动机控制等方向,能够解决降低载波频率、成本上升、变化等问题,达到防止磁体温度上升、防止开关损失的增大的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. Hereinafter, the same reference numerals are assigned to the same or corresponding parts in the drawings, and detailed description thereof will not be repeated in principle.

[0045] (Overall structure of the system)

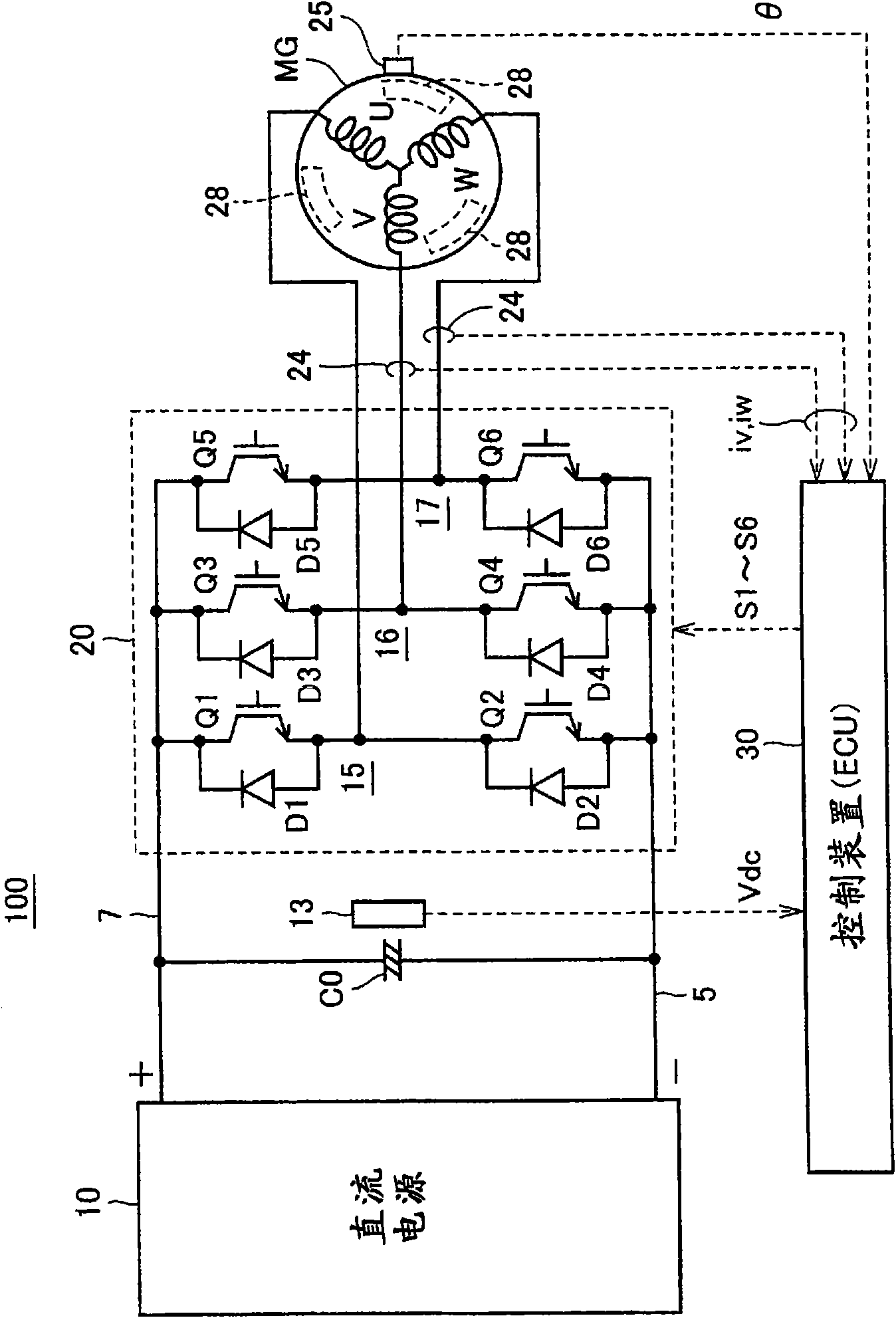

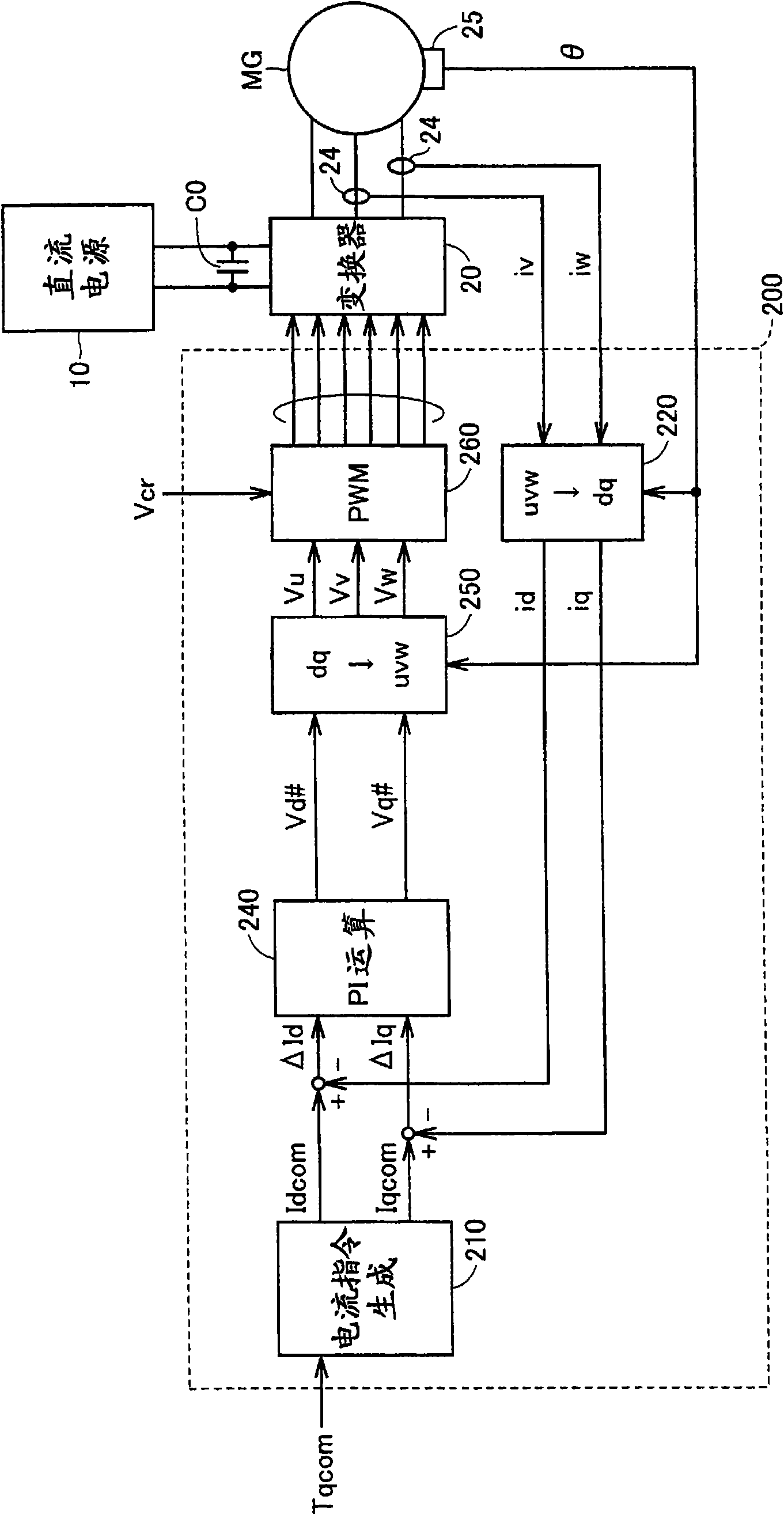

[0046] figure 1 It is an overall configuration diagram of the motor drive system according to the embodiment of the present invention.

[0047] refer to figure 1 , The motor drive system 100 according to the embodiment of the present invention includes a DC power supply 10 , a voltage sensor 13 , a smoothing capacitor C0 , an inverter 20 , a control device 30 , and an AC motor MG as a load.

[0048] AC motor MG is, for example, a drive motor for generating torque for driving drive wheels of a hybrid vehicle or an electric vehicle. Alternatively, the AC motor MG may be configured to function as a generator driven by the engine, or may be config...

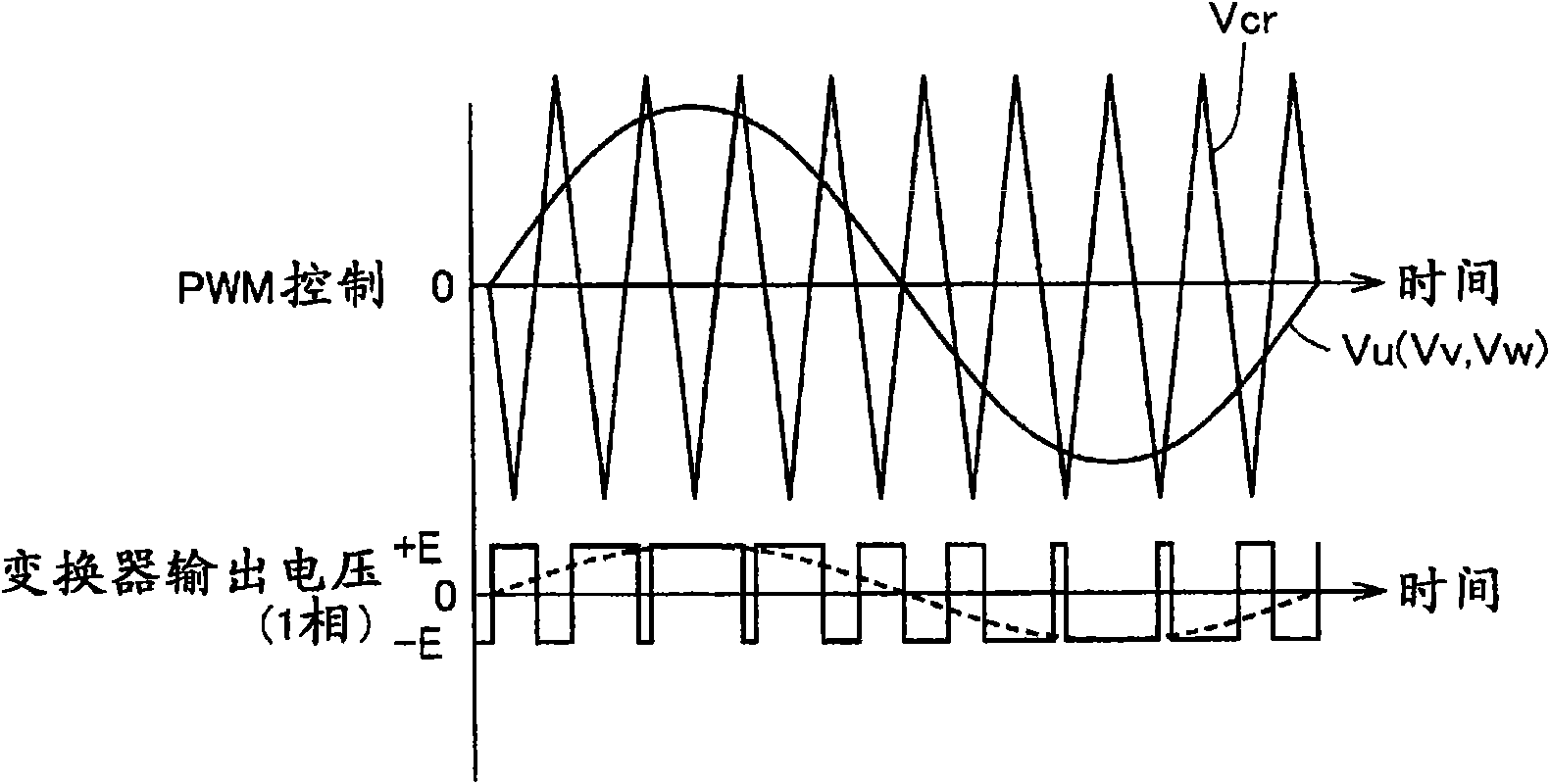

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com