High strength low alloy wear resistance steel plate and preparation method thereof

A high-strength, low-alloy, wear-resistant steel plate technology, applied in temperature control and other directions, can solve problems such as the influence of steel plate welding performance, increase steel carbon equivalent, etc., so as to save the intermediate waiting time, shorten the rolling cycle, and improve hardenability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The specific chemical composition of the 12mm thick high-strength wear-resistant steel plate in Example 1 is shown in Table 1:

[0029] Table 1 is the chemical composition (mass percentage, %) of steel of embodiment 1

[0030]

[0031] Carry out vacuum smelting according to the above chemical composition ratio, and cast into blanks.

[0032] The slab is heated to 1180~1200°C, and the heating time is ≥150min.

[0033] The reduction rate of each hot rolling pass is 15~30%, the cumulative reduction rate is ≥70%, the starting temperature of hot rolling is 1050~1100°C, and the ending temperature is ≥950°C.

[0034] Heat treatment (quenching + low temperature tempering) is carried out after the steel plate is rolled.

[0035] Quenching system: heating to 950°C, holding time 36min, water cooling; tempering system: heating to 250°C, holding time 30min, air cooling.

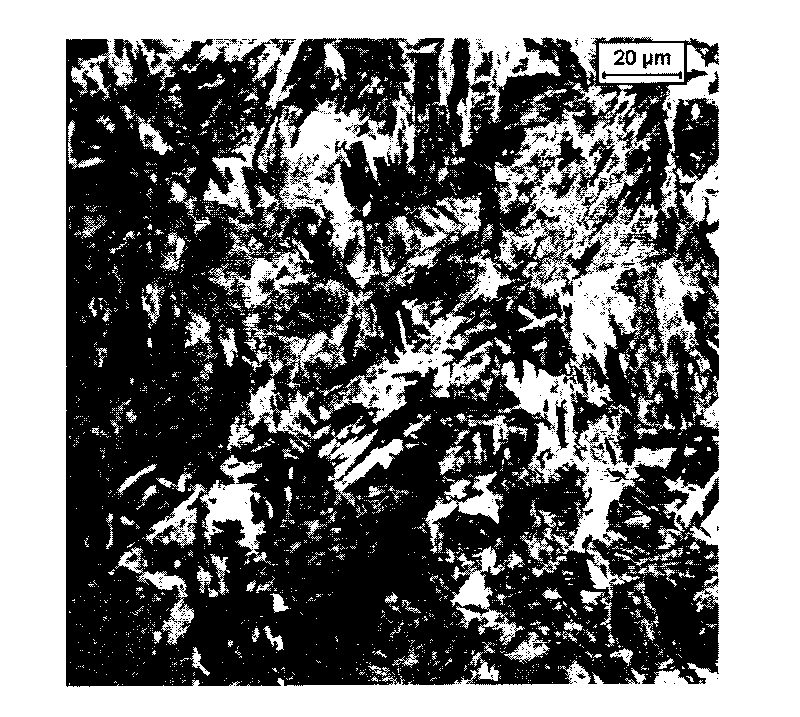

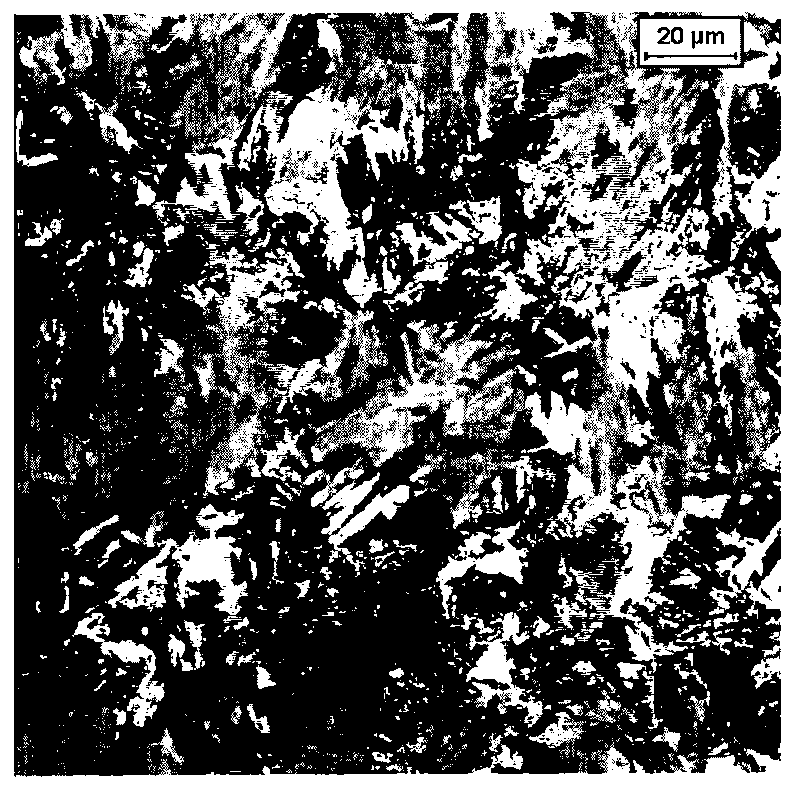

[0036] After heat treatment, a composite structure of martensite with high hardness, a small amount of ret...

Embodiment 2

[0041] The specific chemical composition of the 12mm thick high-strength wear-resistant steel plate in Example 2 is shown in Table 3:

[0042] Table 3 is the chemical composition (mass percentage, %) of embodiment 2 steel

[0043]

[0044] Carry out vacuum smelting according to the above chemical composition ratio, and cast into blanks.

[0045] The slab is heated to 1180~1200℃, and the heating time is at least ≥150min;

[0046] The reduction rate of each pass of hot rolling is 15-30%, the cumulative reduction rate is ≥70%, the hot-rolling start temperature is 1050-1100°C, and the end temperature is ≥950°C. The steel plate is heat-treated after rolling, and tempered at low temperature after quenching.

[0047] Quenching system: heating to 950°C, holding time 36min, water cooling; tempering system: heating to 250°C, holding time 30min, air cooling.

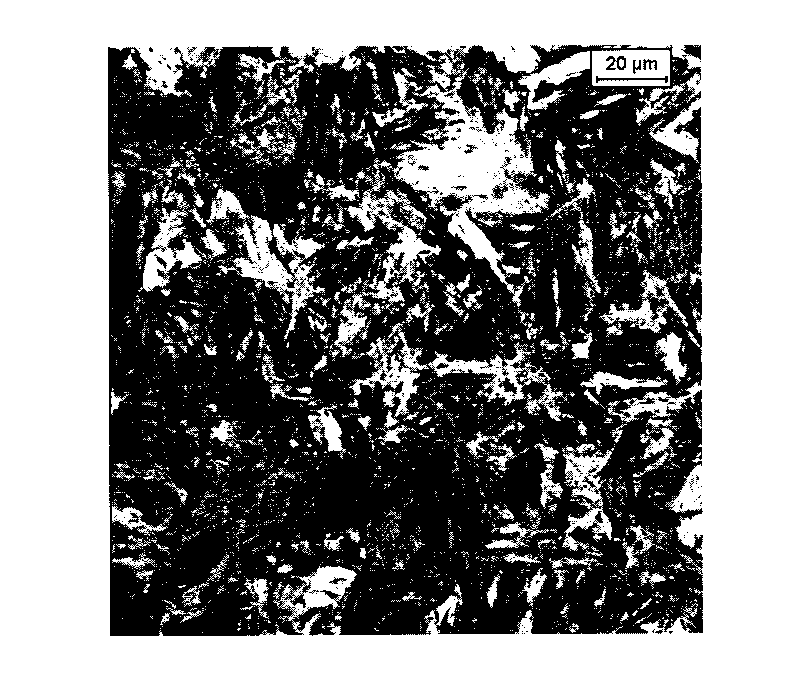

[0048] After heat treatment, a composite structure of martensite with high hardness, a small amount of retained austenite wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com