Separation method of lead-zinc sulphide minerals

A separation method and mineral technology, applied in solid separation, flotation and other directions, can solve the problems of unsatisfactory flotation separation effect, environmental damage, large dosage of chemicals, etc., and achieve improved production conditions, less environmental pollution, and strong inhibition ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

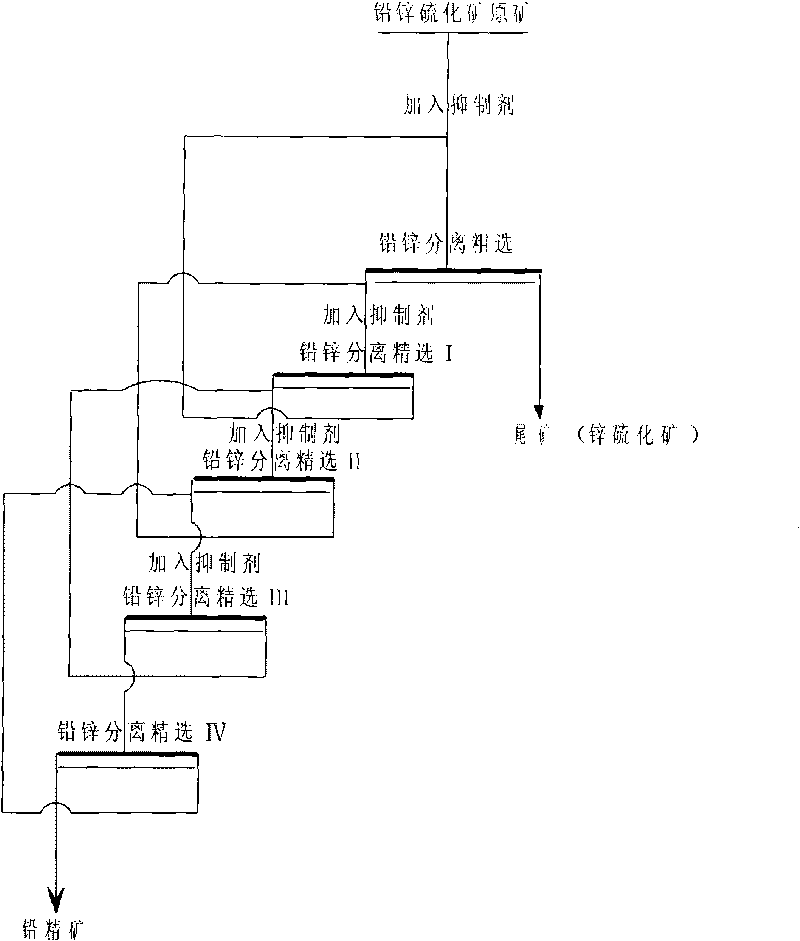

[0017] This embodiment 1 provides a method for separating lead-zinc sulfide minerals, which uses the raw ore of lead-zinc sulfide minerals as raw material, and performs preferential flotation separation on the raw ore of lead-zinc sulfide minerals to obtain lead concentrate minerals. The method includes :

[0018] Using the raw ore of lead-zinc sulfide minerals as raw material, separate and roughen the raw ore of lead-zinc sulfide minerals to obtain lead rough concentrate minerals; in the process of separating and roughing the raw ore of lead-zinc sulfide minerals, add water-soluble thioglycolate or mercapto Acetic acid as an inhibitor of zinc sulfide minerals in the separated minerals;

[0019] Afterwards, the obtained lead coarse concentrate minerals are refined and separated to obtain lead concentrate minerals. In the process of refining lead concentrate minerals, water-soluble thioglycolate or thioglycolic acid is also added as Inhibitors of zinc sulfide minerals.

[002...

Embodiment 2

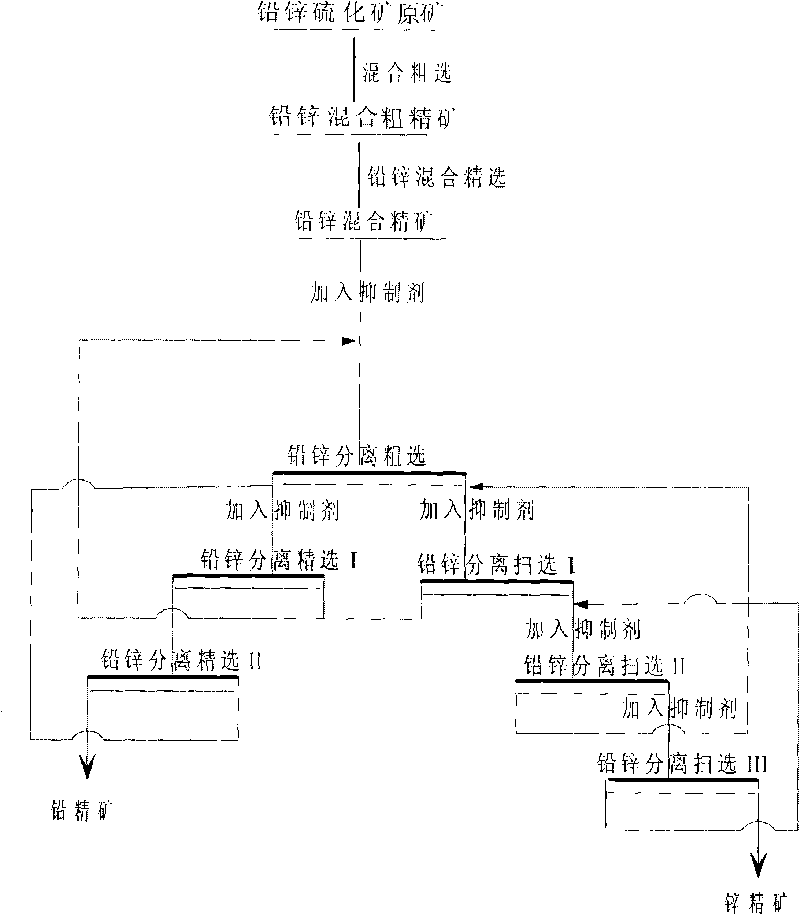

[0028] Present embodiment 2 provides a kind of separation method of lead-zinc sulfide mineral, is to be raw material with the raw ore of lead-zinc sulfide mineral, the raw ore of this lead-zinc sulfide mineral is carried out preferential flotation separation to obtain the method for lead concentrate mineral, this method and The separation method that embodiment 1 provides is basically the same, and the difference is that in the flotation separation process to minerals, potassium thioglycolate is used as the inhibitor to zinc sulfide minerals in the separated minerals, and the specific steps are as follows:

[0029] The raw ore grade of the lead-zinc ore used is Pb 3.42%, Zn 11.24%. The raw ore is added to the flotation tank for lead-zinc separation and roughing operation. During the separation and roughing process, potassium thioglycolate is added as the zinc sulfide mineral in the separated minerals Inhibitor, the amount of inhibitor added is 1000g / t, that is, 1000g inhibitor ...

Embodiment 3

[0033] Present embodiment 3 provides a kind of separation method of lead-zinc sulfide mineral, is to be raw material with the raw ore of lead-zinc sulfide mineral, carries out preferential flotation separation to the raw ore of this lead-zinc sulfide mineral and obtains the method for lead concentrate mineral, this method and The separation method that embodiment 1 provides is basically the same, and the difference is that in the flotation separation process to minerals, ammonium thioglycolate is used as the inhibitor to zinc sulfide minerals in the separated minerals, and the specific steps are as follows:

[0034] The raw ore grade of the lead-zinc ore used is Pb 3.61%, Zn 2.93%, and the raw ore is added to the flotation tank for lead-zinc separation and roughing operation. During the separation and roughing process, ammonium thioglycolate is added as the zinc sulfide mineral in the separated minerals Inhibitor, the amount of inhibitor added is 510g / t, that is, 510g inhibitor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com