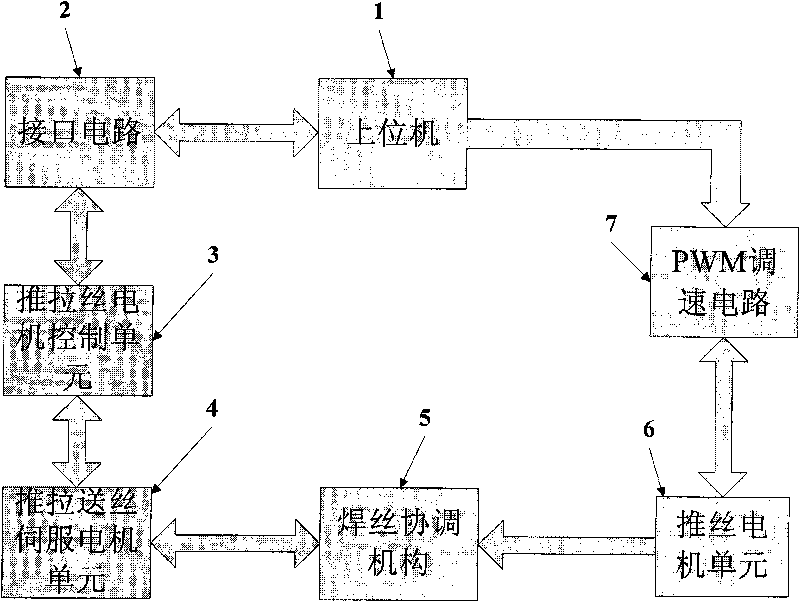

Wire feeding system of double-motor combined welding wire coordinating mechanism

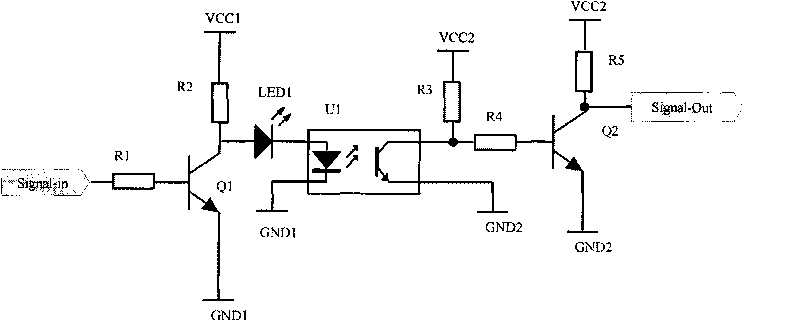

A technology of wire feeding system and dual motors, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as lost steps, difficult practical application, high requirements for dynamic response speed of welding wire, etc., and achieve real-time feeding and feeding Smooth, anti-interference ability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiment of the present invention will now be described in detail through a specific example.

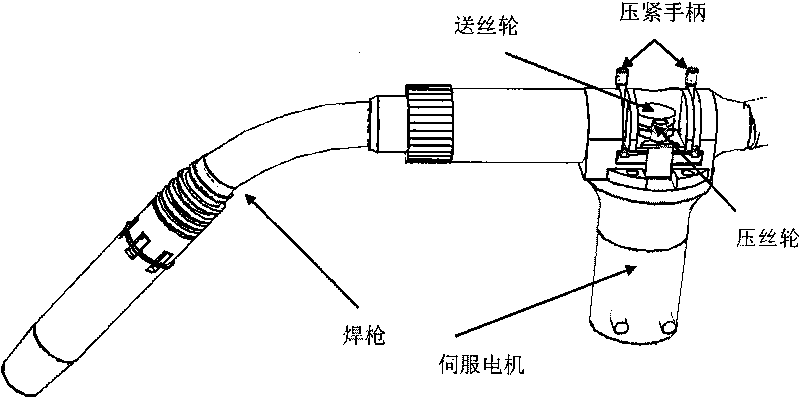

[0020] The push-pull wire-feeding servo motor is BLS40 three-phase synchronous precision AC servo motor produced by Mavero, Spain, and the motion control card is PMAC2-PC104 motion control card from Delta Tau, USA.

[0021] At the beginning of welding, after receiving the signal from the welding torch, the host computer 1 sends the wire feeding speed to the PWM speed regulating circuit 7 and the motion control card to start wire feeding and arc ignition. After the arc ignition is successful, the wire pushing motor 6 is fed at a constant speed The welding wire and the motion control card drive the push-pull wire motor to move forward and reverse according to the received welding status signal, so that the welding wire is fed or withdrawn. Because the push-pull motor keeps repeating the process of feeding-retracting, and the wire-pushing motor keeps feeding, therefore, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com