a dissolution system

A technology of outlet main pipe and unit, applied in the field of dissolution system, can solve the problems of high operating cost, large investment, pipeline breakage, etc., achieve the effect of reducing high investment and operating cost, safe and reliable system, and eliminating vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

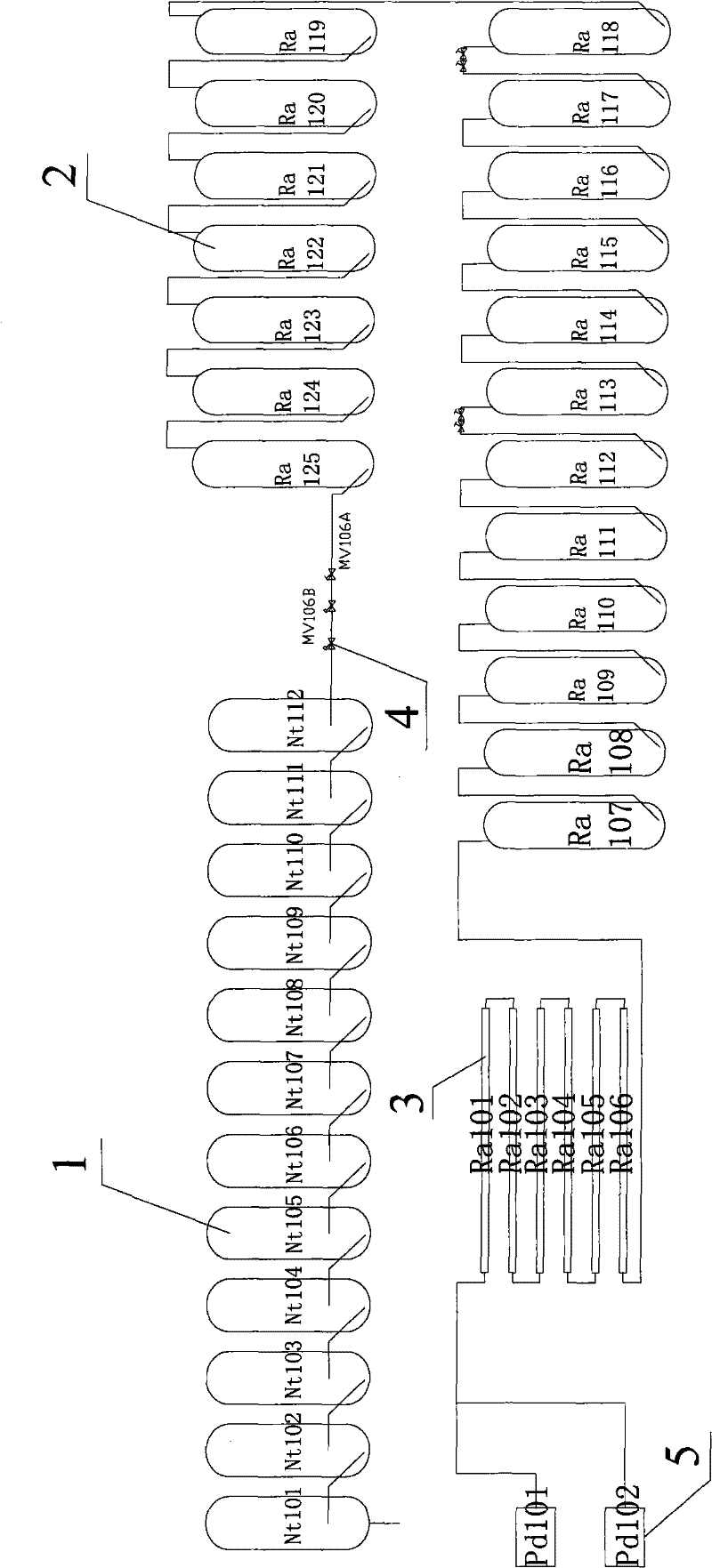

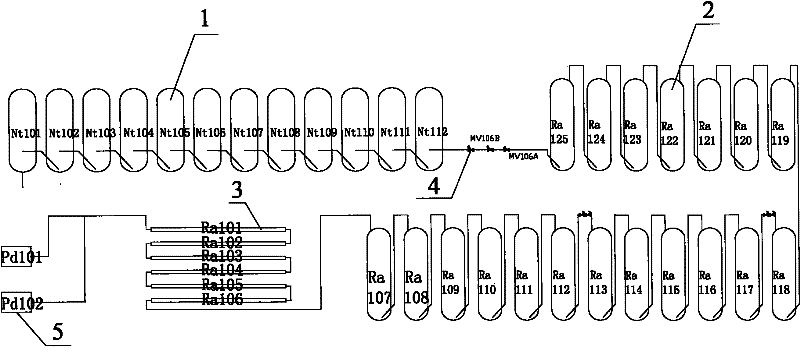

[0017] The stripping system proposed by the present invention is no longer configured with a pulse buffer, and at the same time cancels the supporting radioactive source, instrumentation, air compressor, high-pressure gas storage tank, etc., as follows with reference to the accompanying drawings.

[0018] Such as figure 1 The dissolution system shown includes: a dissolution unit consisting of a flash distillation unit 1 and a dissolution autoclave unit 2, a preheating sleeve 3 and a diaphragm pump 5, the diaphragm pump 5 is connected to the preheating sleeve 3 through a pipeline, and the preheating sleeve The pipe 3 is connected to the dissolution autoclave unit 2, and a slurry regulating valve 4 (MV106C) is added to the connecting pipeline between the final outlet of the dissolution autoclave unit 2 and the flash evaporation unit 1.

[0019] At least two diaphragm pumps 5 are configured, each of which is equipped with a pipeline, and the pipelines are rejoined at the inlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com