Optimal design method of AAO process reaction tank

An optimized design and reaction pool technology, applied in chemical instruments and methods, aerobic and anaerobic process treatment, calculation, etc., can solve the problems of lack of engineering data verification, results tend to be biased towards theory, and cannot meet engineering specifications, etc. Achieve the effect of reducing infrastructure investment, good economic benefits, and saving volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

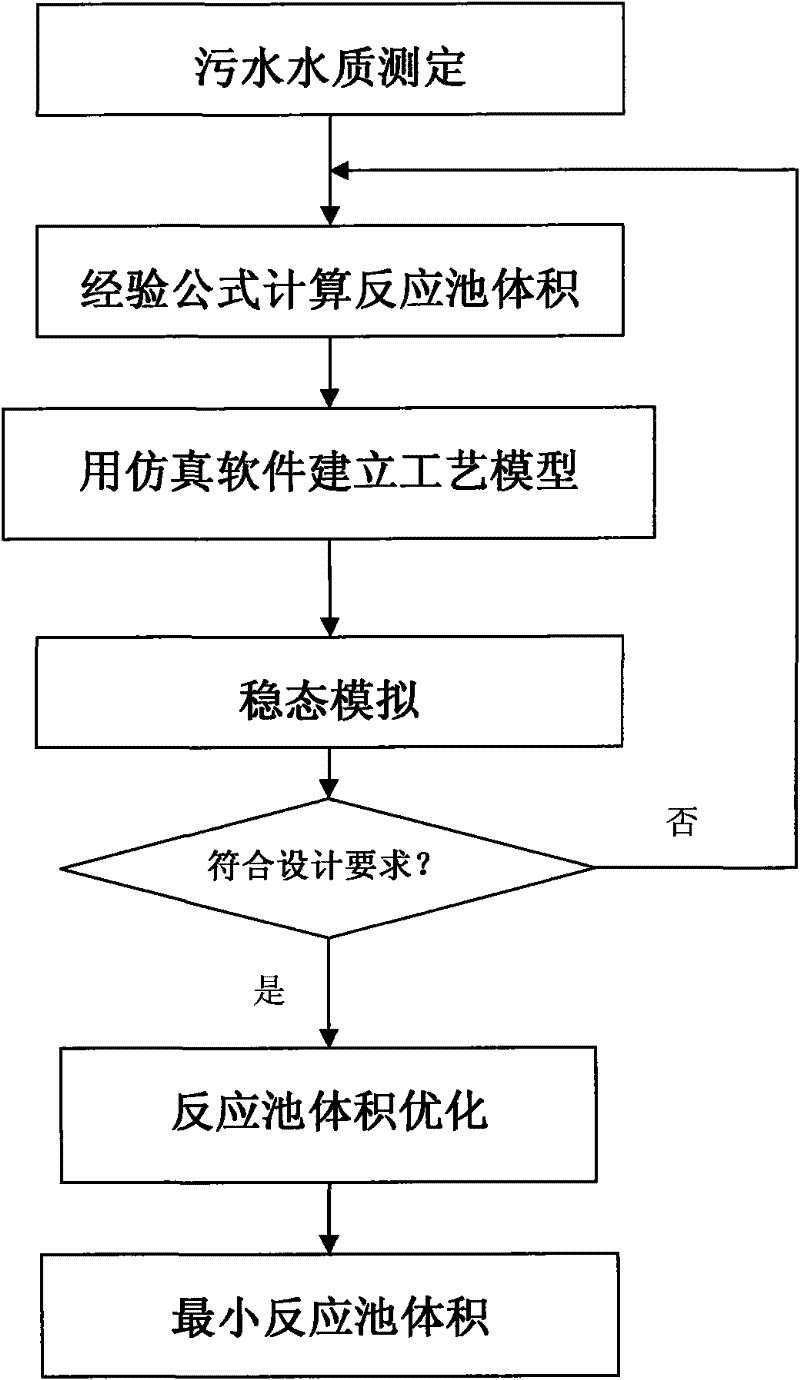

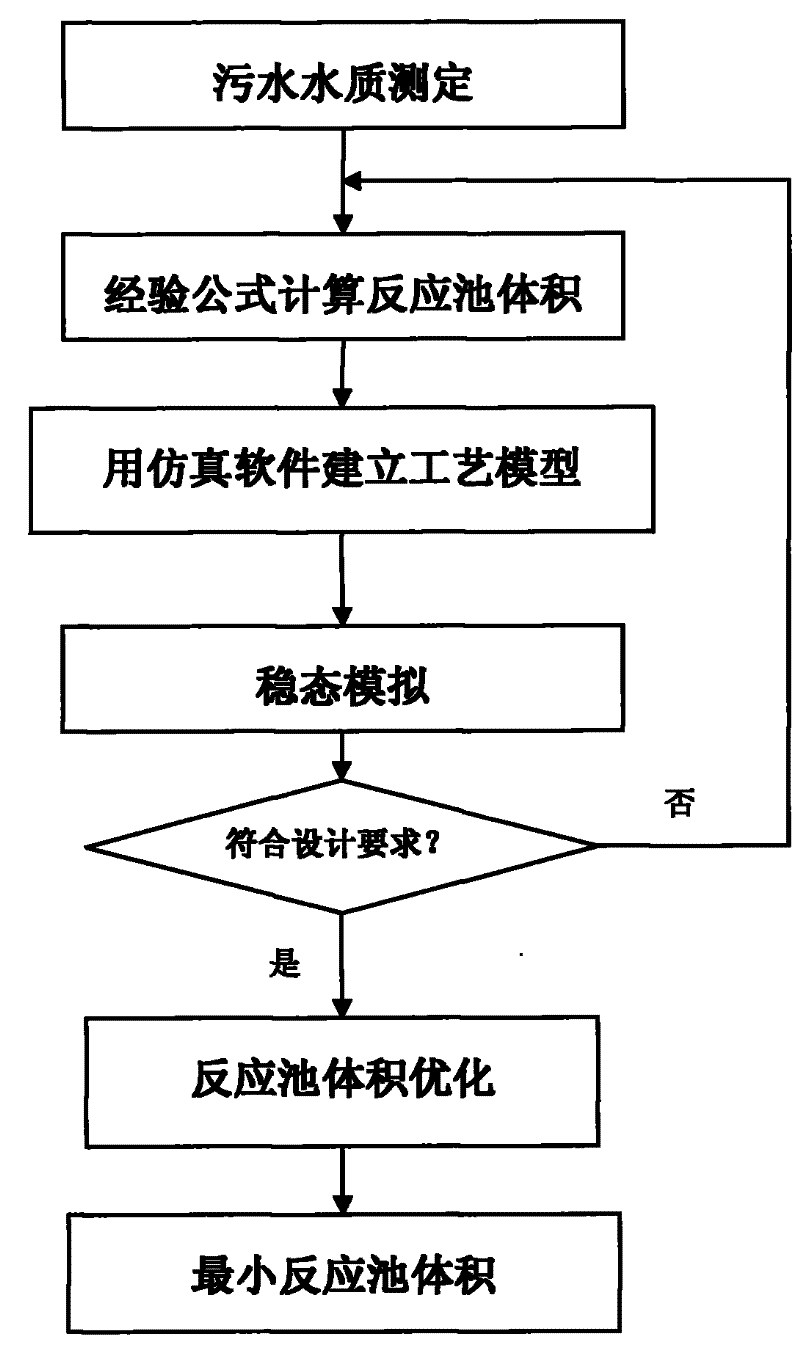

[0036] To treat water Q = 30000m 3 / d AAO process design for urban sewage treatment as an example, such as figure 1 As shown in the flow chart, use the GPS-X simulation software to design the volume of the biological reaction pool. The design requirements meet the first-class B standard in GB18918-2002 for COD Cr , TN and SS and other three main parameters of the control requirements (design water temperature 20 ℃): COD Cr <60mg / L, TN<20mg / L, SS<20mg / L.

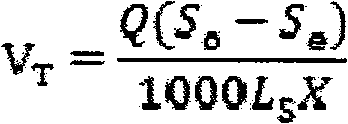

[0037] Step 1, measure the water quality parameters of the influent, and calculate the main parameters of the AAO process according to the empirical formula and empirical parameters:

[0038] 1. Determination of water quality parameters of influent

[0039] According to the national standard method, the water quality parameters of the influent water are: COD Cr 440mg / L, soluble COD Cr 154mg / L, BOD 5 208mg / L, soluble BOD 566mg / L, TSS 217mg / L, VSS 130mg / L, TKN 40mg / L, soluble TKN 32mg / L, TN 40mg / L, NH 3 -N is 28.8mg / L,...

Embodiment 2

[0070] To treat water Q = 30000m 3 / d AAO process design for urban sewage treatment as an example, such as figure 1 As shown in the flow chart, use the WEST simulation software to design the volume of the biological reaction tank. The design requirements meet the first-class B standard in GB18918-2002 for COD Cr , TN and SS and other three main parameters of the control requirements (design water temperature 20 ℃): COD Cr <60mg / L, TN<20mg / L, SS<20mg / L.

[0071] Step 1, measure the water quality parameters of the influent, and calculate the main parameters of the AAO process according to the empirical formula and empirical parameters:

[0072] 1. Determination of water quality parameters of influent

[0073] According to the national standard method, the water quality parameters of the influent water are: COD Cr 440mg / L, soluble COD Cr 154mg / L, BOD 5 208mg / L, soluble BOD 5 66mg / L, TSS 217mg / L, VSS 130mg / L, TKN 40mg / L, soluble TKN 32mg / L, TN 40mg / L, NH 3 -N is 28.8mg / L,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com