Aluminum-zinc-tin system sacrificial anode material and preparation method thereof

A sacrificial anode, aluminum-zinc-tin technology, applied in the field of metal corrosion and protection, can solve the problems of high price, low current efficiency, limited promotion and application, etc., and achieve uniform surface solubility, stable working potential, and good activation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

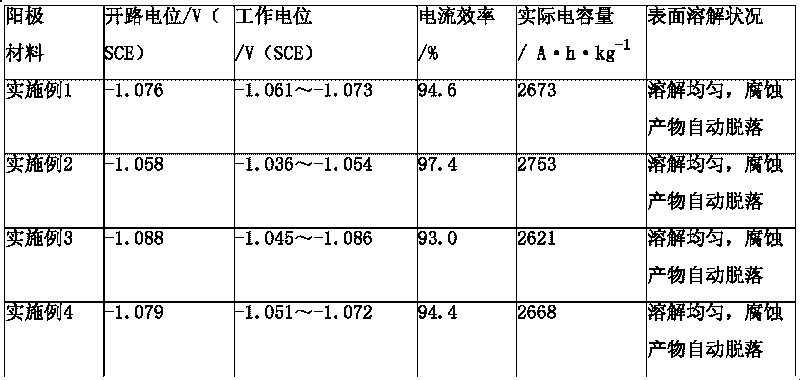

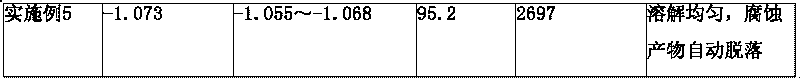

Embodiment 1

[0018] The percentage by weight of each component in the aluminum-zinc-tin sacrificial anode material of this embodiment is: Zn: 8.0%, Sn: 0.2%, Ga: 0.05%, the rest is aluminum, and the impurity content is ≤0.15%. When preparing, put the aluminum-zinc master alloy and aluminum-tin master alloy required for smelting into the crucible of a ZGJL0.01-40-4 induction melting furnace, and heat it under the protection of argon. After the master alloy is melted, the granular gallium component is wrapped by aluminum foil Press it into the crucible, continue heating to 700°C and keep it warm for 20 minutes. During the heat preservation, the crucible rotates automatically, and casts it in a preheated cast iron mold (preheated at 150°C for 0.5h), and takes it out after cooling for 0.5h to make aluminum zinc tin It is a sacrificial anode material. For the prepared Al-Zn-Sn sacrificial anode material, the electrochemical performance of the alloy was tested with a CHI660C electrochemical work...

Embodiment 2

[0020]The weight percentages of the components in the aluminum-zinc-tin sacrificial anode material of this embodiment are: Zn: 7.0%, Sn: 0.1%, Ga: 0.03%, the rest is aluminum, and the impurity content is ≤0.15%. During preparation, the aluminum-zinc master alloy, aluminum-tin master alloy and granular gallium required for melting are put into a ZGJL0.01-40-4 vacuum induction melting furnace for melting, and the melting temperature is 760°C for 8 minutes. During the heat preservation, the crucible rotates automatically. Pouring molding in a hot cast iron mold (preheating the cast iron mold at 150°C for 0.5h), taking it out after cooling for 0.5h, and making an Al-Zn-Sn sacrificial anode material. For the prepared aluminum alloy sacrificial anode material, the electrochemical performance of the alloy was tested with a CHI660C electrochemical workstation according to the electrochemical performance test method specified in the GT / T4948-2002 standard. The open circuit potential of...

Embodiment 3

[0022] The weight percentages of the components in the Al-Zn-Sn sacrificial anode material in this embodiment are: Zn: 6.0%, Sn: 0.05%, Ga: 0.01%, the rest is aluminum, and the impurity content is ≤0.15%. When preparing, put the aluminum-zinc master alloy and aluminum-tin master alloy required for smelting into the crucible of a ZGJL0.01-40-4 induction melting furnace, and heat it under the protection of argon. After the master alloy is melted, the granular gallium component is wrapped by aluminum foil Press it into the crucible, continue heating to 740°C for 10 minutes, the crucible rotates automatically during the heat preservation, pour into the preheated cast iron mold (cast iron mold is preheated at 150°C for 0.5h), take it out after cooling for 0.5h, and make aluminum zinc tin It is a sacrificial anode material. For the prepared aluminum alloy sacrificial anode material, the electrochemical performance of the alloy was tested with a CHI660C electrochemical workstation ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com