Boiler fly ash ignition carbon measuring device

A fly ash and boiler technology, which is applied to the field of boiler fly ash burning carbon measurement devices, can solve the problems of inability to guide the boiler combustion adjustment in time, weighing rod shaking, affecting measurement accuracy, etc. The effect of strengthening the ability and improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

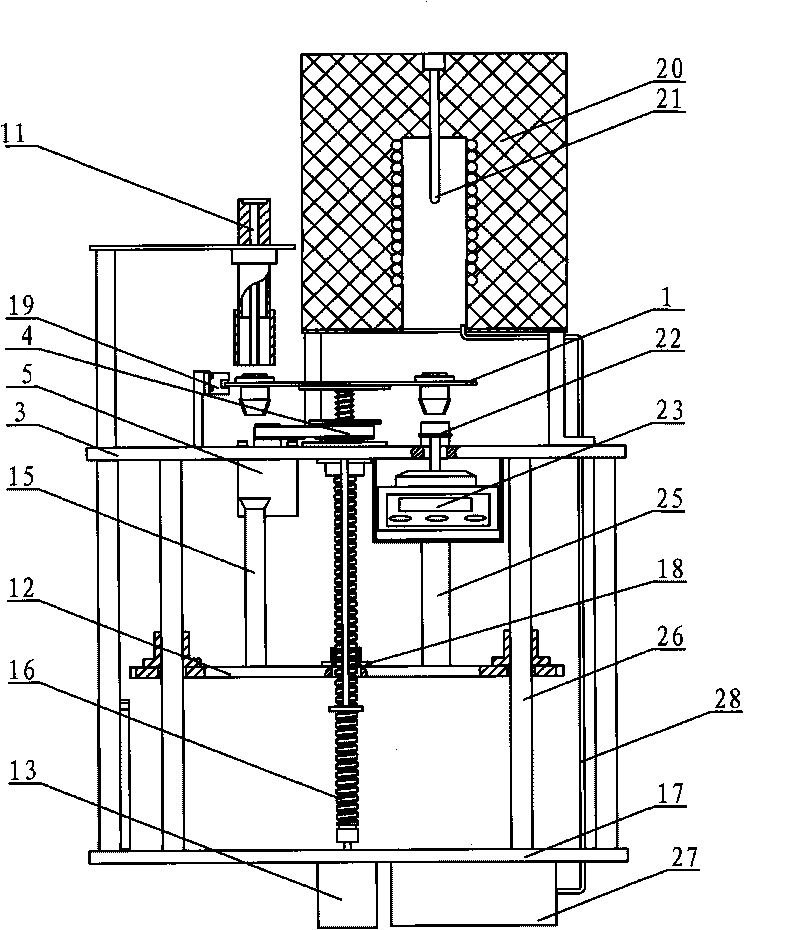

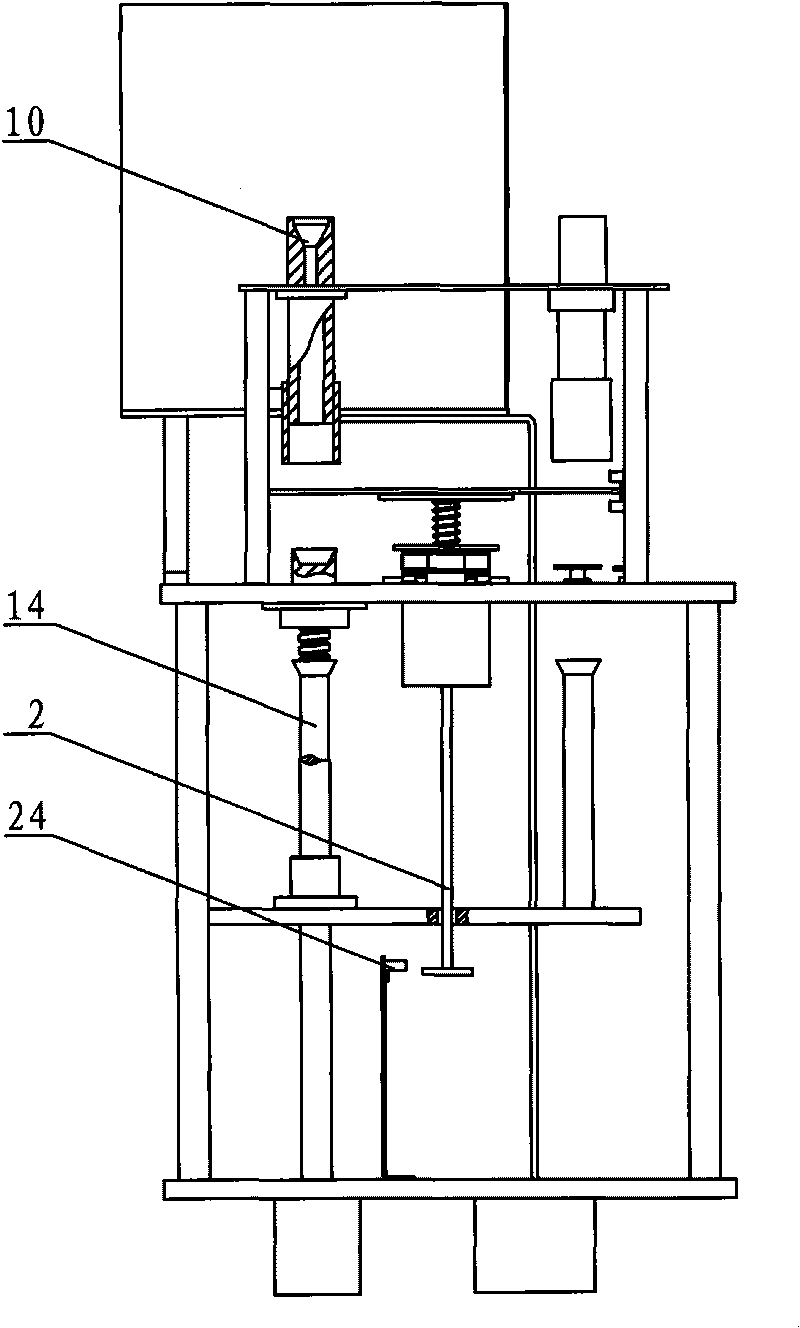

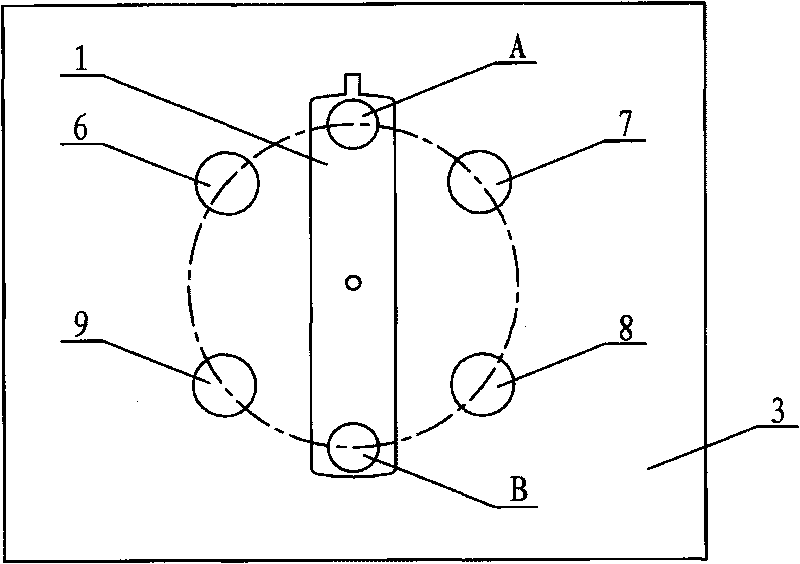

[0022] Such as figure 1 , 2 , 3, 4, 5 and 6, the boiler fly ash burning carbon measuring device of the present invention includes a transmission part, a sample adding part, a burning part, a weighing part, a sample layout part, a station platform and an electrical control system .

[0023] The station platform 3 is provided with four circular through holes distributed in concentric circles, which are arranged in clockwise order: sample adding station 6, burning station 7, sample weighing station 8 and sample layout station 9 . Wherein, the sample adding part 10 is positioned directly above the sample loading station 6, the sample discharge part 11 is positioned directly above the sample discharge station 9, the burning part is positioned directly above the burning station 7, and the sample weighing part is positioned at the sample weighing station. below bit 8.

[0024] The conveying parts include a crucible support plate 1, a pull rod 2, a transposition motor 5, a lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com