Series radio-frequency micro-electromechanical switch amplified on basis of heat driving and preparation method of same

A micro-electromechanical, thermally driven technology, applied in the direction of generators/motors, processes for creating decorative surface effects, piezoelectric effect/electrostrictive or magnetostrictive motors, etc. Life reduction and other problems, to achieve the effect of preventing signal attenuation, high yield, and preventing damage to RF devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

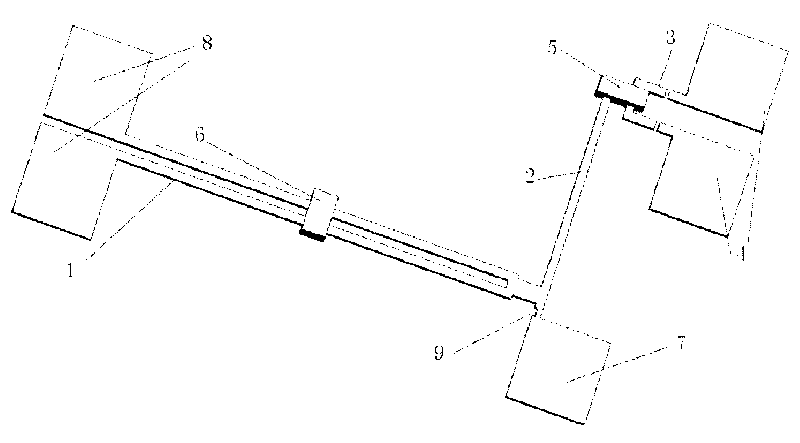

[0043] Such as figure 1As shown, this embodiment includes: a thermally driven arm 1, an amplifying arm 2, a contact block 4, an isolation block 5, a fixed end of the amplifying arm 2 and a fixed end of the thermally actuated arm 1, wherein: two thermally actuated arms 1 are parallel to each other and one end It is fixedly connected with one end of the amplifying arm 2, the other ends of the two thermal driving arms 1 are respectively connected with the fixed ends of the two thermal actuating arms 1, and the end of the amplifying arm 2 near the thermal actuating arm 1 is connected with the fixed end of the amplifying arm 2, The other end of the amplifying arm 2 is connected with the isolation block 5 , and the isolation block 5 is arranged opposite to the two contact blocks 4 .

[0044] In this embodiment: the length of the connecting contact 3 is 50 μm, and the width is 30 μm; the length of the thermally driven arm 1 is 500 μm; the length of the amplifying arm 2 is 250 μm; the...

Embodiment 2

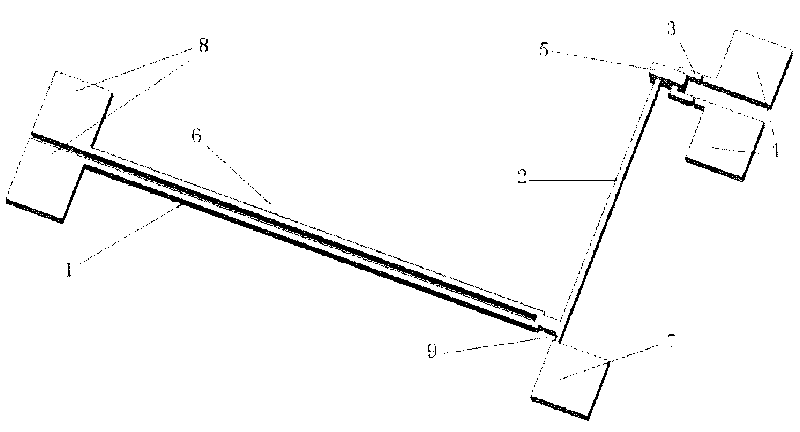

[0054] Such as figure 2 As shown, this embodiment includes: a thermally driven arm 1, an amplifying arm 2, a contact block 4, an isolation block 5, a fixed end of the amplifying arm 2 and a fixed end of the thermally actuated arm 1, wherein: two thermally actuated arms 1 are parallel to each other and one end It is fixedly connected with one end of the amplifying arm 2, the other ends of the two thermal driving arms 1 are respectively connected with the fixed ends of the two thermal actuating arms 1, and the end of the amplifying arm 2 near the thermal actuating arm 1 is connected with the fixed end of the amplifying arm 2, The other end of the amplifying arm 2 is connected with the isolation block 5 , and the isolation block 5 is arranged opposite to the two contact blocks 4 .

[0055] In this embodiment: the length of the connecting contact 3 is 80 μm, and the width is 50 μm; the length of the thermally driven arm 1 is 800 μm; the length of the amplifying arm 2 is 500 μm; t...

Embodiment 3

[0066] The length of the connecting contact 3 is 80 μm, and the width is 50 μm; the length of the thermal driving arm 1 is 800 μm; the length of the amplification arm 2 is 500 μm; the thickness is 30 μm, and the line width of each part is 20 μm; the length of the anti-short circuit block 6 is 800 μm, the thickness is 50 μm, and the width is 80 μm ; The length of the SU8 spacer 5 is 80 μm, the thickness is 50 μm, and the width is 50 μm; the fulcrum distance is 50 μm; the gap distance is 8 μm.

[0067] Such as figure 2 As shown, in this embodiment, the structure of the switch is basically the same as that of Embodiment 2. The difference is that the anti-short circuit block 6 wraps the entire heating arm, which can enhance the stability of the heating arm and prevent the heating arm from being deformed by force. In addition, this will reduce the cooling rate of the switch, and the result is that the switch turns on faster and the switch turns off slower.

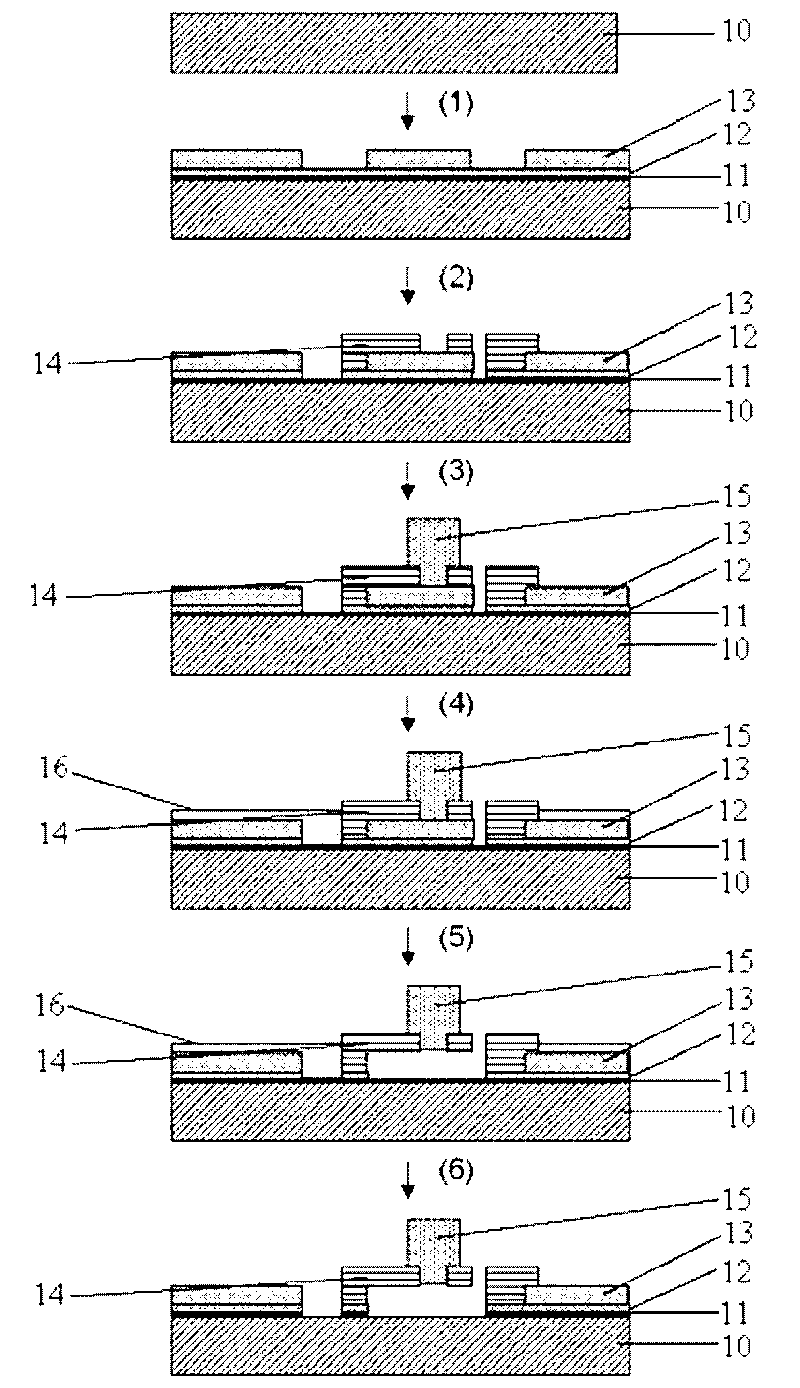

[0068] Such as ima...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com