Method for preparing cold-brewing tea by puffing at variable temperature and pressure differences

A technology of variable temperature and pressure difference puffing and cold brewing of tea, which is applied in the field of food processing, can solve the problems of preparing cold brewed tea, achieve efficient extraction and reduce the effect of mass transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The method for preparing cold-brewed tea by variable temperature and pressure difference puffing consists of the following steps:

[0026] (1) add water to green tea to make the mass content of water reach 40%, and place it at 10°C for 36h;

[0027] (2) Freeze at -14°C for 30 hours, then warm up to 4°C to thaw;

[0028] (3) Step (2) is repeated twice;

[0029] (4) Put it into a variable temperature and pressure difference airflow expansion tank, heat it indirectly with steam to 100°C, keep the temperature for 6 minutes, reduce the pressure from 0.13MPa to 100Pa in 120 seconds, cool down to 80°C, and vacuum at a pressure of 100Pa After drying for 150 minutes, cold brewed tea was obtained.

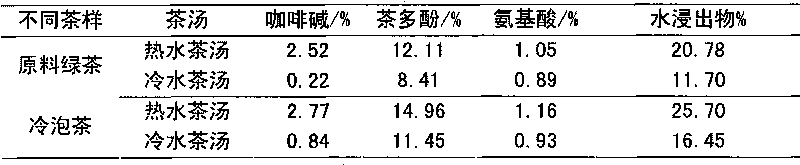

[0030] The raw material (green tea) and the biochemical composition of the cold-brewed tea prepared in Example 1 are shown in Table 1.

[0031] Table 1

[0032]

Embodiment 2

[0034] The method for preparing cold-brewed tea by variable temperature and pressure difference puffing consists of the following steps:

[0035] (1) Put the fresh tea leaves at 4°C for 24 hours after finishing and kneading;

[0036] (2) Freeze at -18°C for 10 hours, then warm up to 6°C to thaw;

[0037] (3) Step (2) is repeated twice;

[0038] (4) Put it into the expansion tank with variable temperature and pressure difference airflow, heat it indirectly with steam to 110°C, keep the temperature for 4min, reduce the pressure from 0.18MPa to 100Pa in 150 seconds, cool down to 80°C, and vacuum at a pressure of 180Pa Dry for 200 minutes to get cold brewed tea.

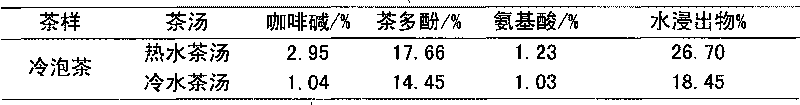

[0039] The biochemical components of the cold-brewed tea were analyzed in Table 2.

[0040] Table 2

[0041]

Embodiment 3

[0043] The method for preparing cold-brewed tea by variable temperature and pressure difference puffing consists of the following steps:

[0044] (1) Add water to black tea to make the mass content of water reach 20%, and place it at 6°C for 30h;

[0045] (2) Freeze at -16°C for 15 hours, then warm up to 8°C to thaw;

[0046] (3) Step (2) is repeated 3 times;

[0047] (4) Put it into a variable temperature and pressure difference airflow expansion tank, heat it indirectly with steam to 120°C, keep the temperature for 5 minutes, reduce the pressure from 0.13MPa to 100Pa in 60 seconds, cool down to 80°C, and vacuum at a pressure of 150Pa After drying for 150 minutes, cold brewed tea was obtained.

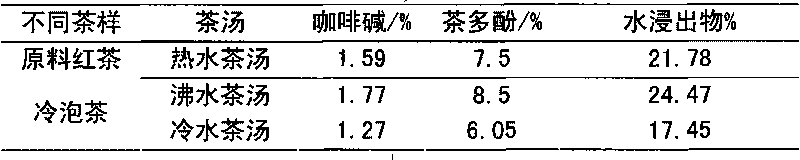

[0048] The biochemical components of raw black tea and cold brewed tea were analyzed as shown in Table 3.

[0049] table 3

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com