Electronic mechanical and hydraulic two-purpose brake

An electro-mechanical and hydraulic technology, applied in the types of brakes, axial brakes, brake components, etc., can solve the problems of difficult reliability, complex structure of electro-mechanical brakes, slow response speed, etc., and achieve fast response speed. , Weakening performance requirements and size installation requirements, the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The implementation of the invention will be further described below in conjunction with the drawings.

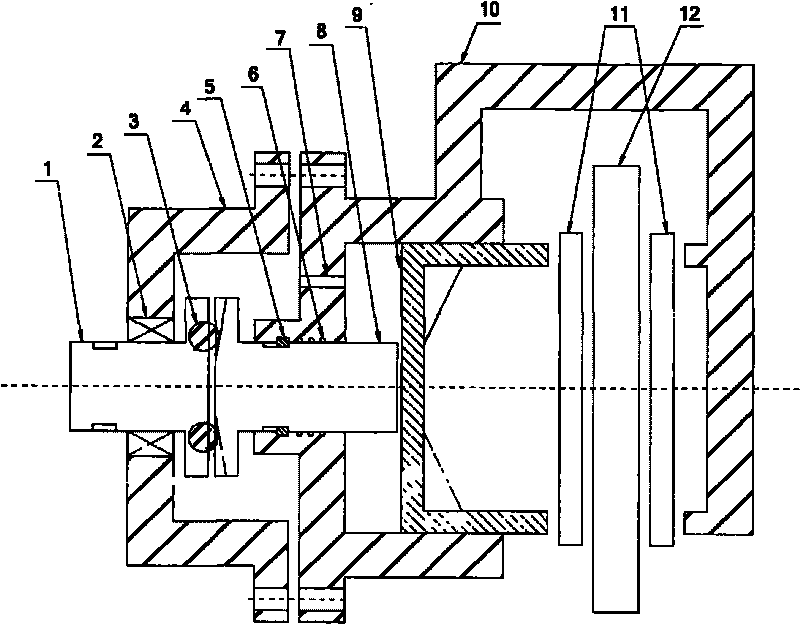

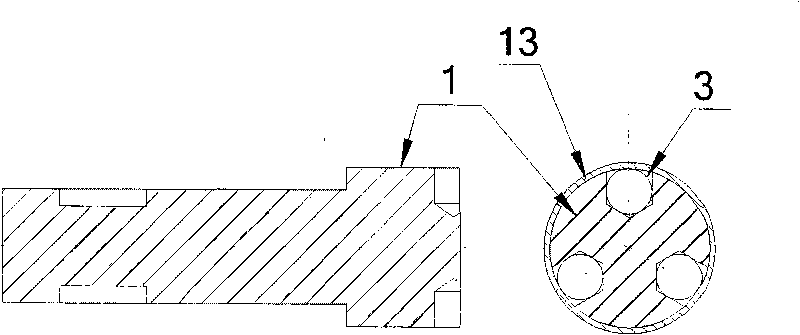

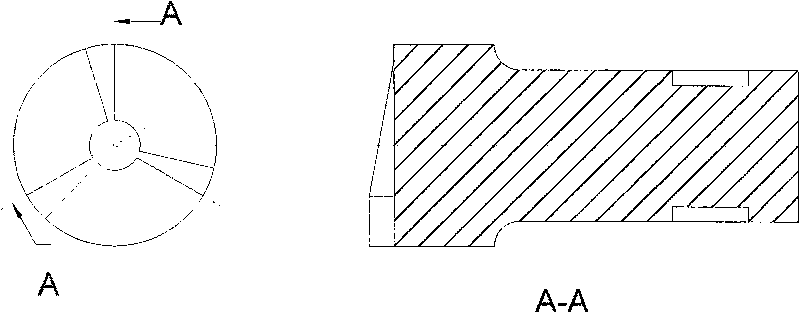

[0019] figure 1 It is a schematic diagram of the principle of the present invention. according to figure 1 As shown, the hydraulic cylinder and the floating clamp assembly 10 have two holes on the end surface of the hydraulic cylinder, one is an oil inlet hole 7 connected with the hydraulic oil pipe, and the other is a hole at the center of the hydraulic cylinder for placing the thrust rod 8. When the hydraulic brake system is working, the brake pedal increases the pressure in the hydraulic cylinder through the main brake pump and the hydraulic oil pipe, pushing the piston 9 and the floating caliper 10 to move relatively, so that the friction block 11 compresses the brake disc 12 to produce Braking torque. When the electromechanical brake system is in effect, the output torque of the torque motor and the reducer generates thrust through the torque input shaft 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com