Catch for etching process and method for preventing catch from jumping

A technology of baffle and process, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of baffle jumping, affecting mass production efficiency, and baffle self-alignment failure, etc., to reduce the strength , low cost, and the effect of increasing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

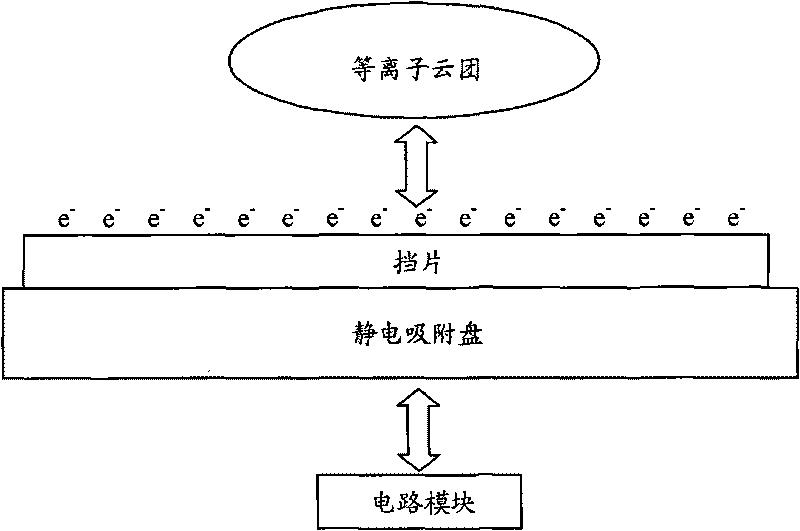

[0012] In order to reduce the probability of chip jumping in the etching process, the present invention proposes the following physical model to explain the process of chip jumping and propose a solution:

[0013] 1. Chip jumping occurs when the electrostatic adsorption disc discharges electrons on the wafer surface;

[0014] 2. During the process of electronic discharge on the surface of the wafer, the wafer will vibrate, and the faster the discharge speed, the stronger the vibration;

[0015] 3. The speed of discharge is related to the equivalent resistance of the block, the greater the resistance, the slower the discharge speed;

[0016] 4. Increasing the weight of the baffle can reduce the intensity of the vibration.

[0017] Based on the above physical model, the solution principle of the present invention is: to increase the equivalent resistance of the baffle, so as to weaken the vibration of the baffle during discharge, thereby reducing the probability of chip jumping...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com