Method for preparing low-melting-point alloy-coated ceramic-phase reinforced body/aluminum-matrix composite materials

A technology of aluminum-based composite materials and reinforcements, which is applied in the field of preparation of low-melting-point alloy-coated ceramic phase reinforcements/aluminum-based composite materials, can solve problems such as complex processes, and achieve the effects of simple processes and shortened production cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0008] Specific embodiment one: the preparation method of low-melting point alloy coating ceramic phase reinforcement / aluminum-based composite material in this embodiment is as follows: 1. Bismuth nitrate aqueous solution, lead nitrate aqueous solution, indium chloride aqueous solution and tin chloride aqueous solution Two or more kinds are added to the dilute nitric acid solution to obtain a mixed solution with a pH value of 1 to 8; 2. Add the mixed solution obtained in step 1 and the ammonia solution dropwise at the same time at a stirring speed of 1r / min to 300r / min Into the aqueous solution of the reinforcement until the pH value is 6-14, stop dropping; 3. Make the reinforcement treated in step 2 into a preform, and then keep the preform at a temperature of 350°C-1100°C for 30min-120min, That is, the ceramic phase reinforcement coated with metal oxide is obtained; 4. Put the ceramic phase reinforcement coated with metal oxide obtained in step 3 into the mold, and then injec...

specific Embodiment approach 2

[0012] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the preparation method of low-melting point alloy coating ceramic phase reinforcement / aluminum matrix composite material is as follows: 1. Bismuth nitrate aqueous solution, lead nitrate aqueous solution, indium chloride aqueous solution and tin chloride aqueous solution are added to dilute nitric acid solution to obtain a mixed solution with a pH value of 6; 2. Add the mixed solution and ammonia solution obtained in step 1 dropwise to the aqueous solution of the reinforcement until the pH value is 10, and the added solution Stir at a speed of 200r / min during the process; 3. Make the reinforced body treated in step 2 into a prefabricated part, and then keep the prefabricated part at a temperature of 1000°C for 100 minutes to obtain a ceramic phase reinforced body coated with metal oxide; 4. Put the metal oxide-coated ceramic phase reinforcement obtained in step 3 into the m...

specific Embodiment approach 3

[0015] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the pH value of the solution is adjusted to 5 in Step 1. Others are the same as in the first or second embodiment.

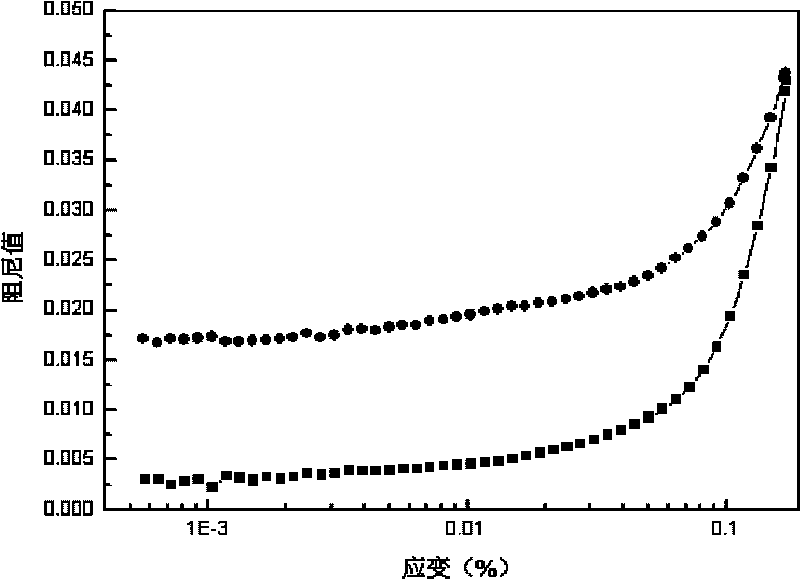

[0016] The damping value of the aluminum matrix composite material prepared by using the ceramic phase reinforcement obtained in this embodiment is 0.016-0.018 at a temperature of 25° C. and a frequency of 70 Hz.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com