On-line soft sensing method for flow of inlet water of ozonation contact reactor in water plant

A technology of ozone contact tank and water inflow flow, which is applied in the direction of relative volume flow measurement, liquid/fluid solid measurement, measuring device, etc., which can solve the problems of inability to measure the real-time flow of ozone contact tank on-line and installation failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

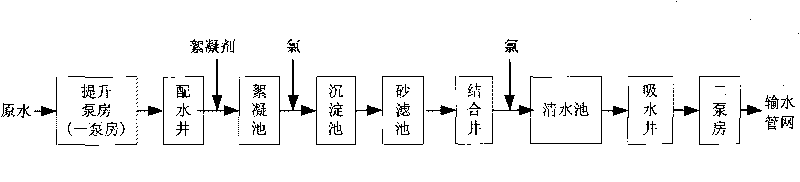

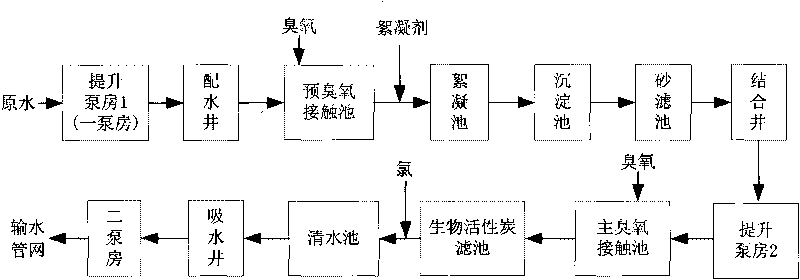

[0049] The technical scheme of the present invention is described in detail below in conjunction with the actual on-line test of Xiangcheng Water Works of Suzhou Water Supply Company:

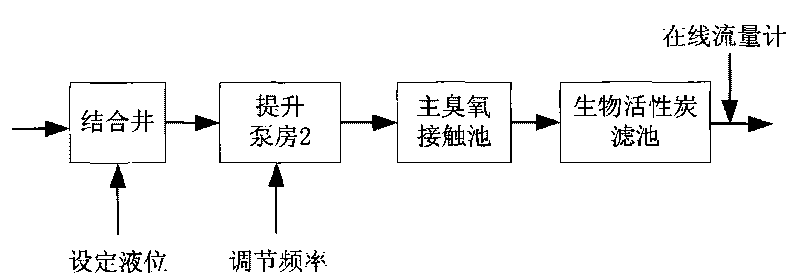

[0050] Such as figure 2 As shown, the water intake of the ozone contact tank of the water plant is formed by self-flow after the lifting pump room 2 in front is lifted, and the lifting pump room 2 usually has multiple lifting water pumps that work in parallel or intermittently in rotation. The lifting pump room 2 lifts the water in the combined well into the ozone contact tank, so the inflow flow of the ozone contact tank is also the total output flow of the lifting pump room 2.

[0051] After the ozone contact tank is an activated carbon filter, and an online flowmeter is installed at the outlet of the activated carbon filter. Under stable working conditions with gentle water flow, no pump room switch car and large frequency adjustment, the inflow flow of the ozone contact tank can be approx...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com