Gas dehumidifying device with controllable supersonic speed of shock wave

A supersonic and shock wave technology, applied in gas fuel, petroleum industry, dispersed particle separation, etc., can solve problems such as unpublished test results, and achieve the effect of avoiding boundary layer separation, good effect and smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

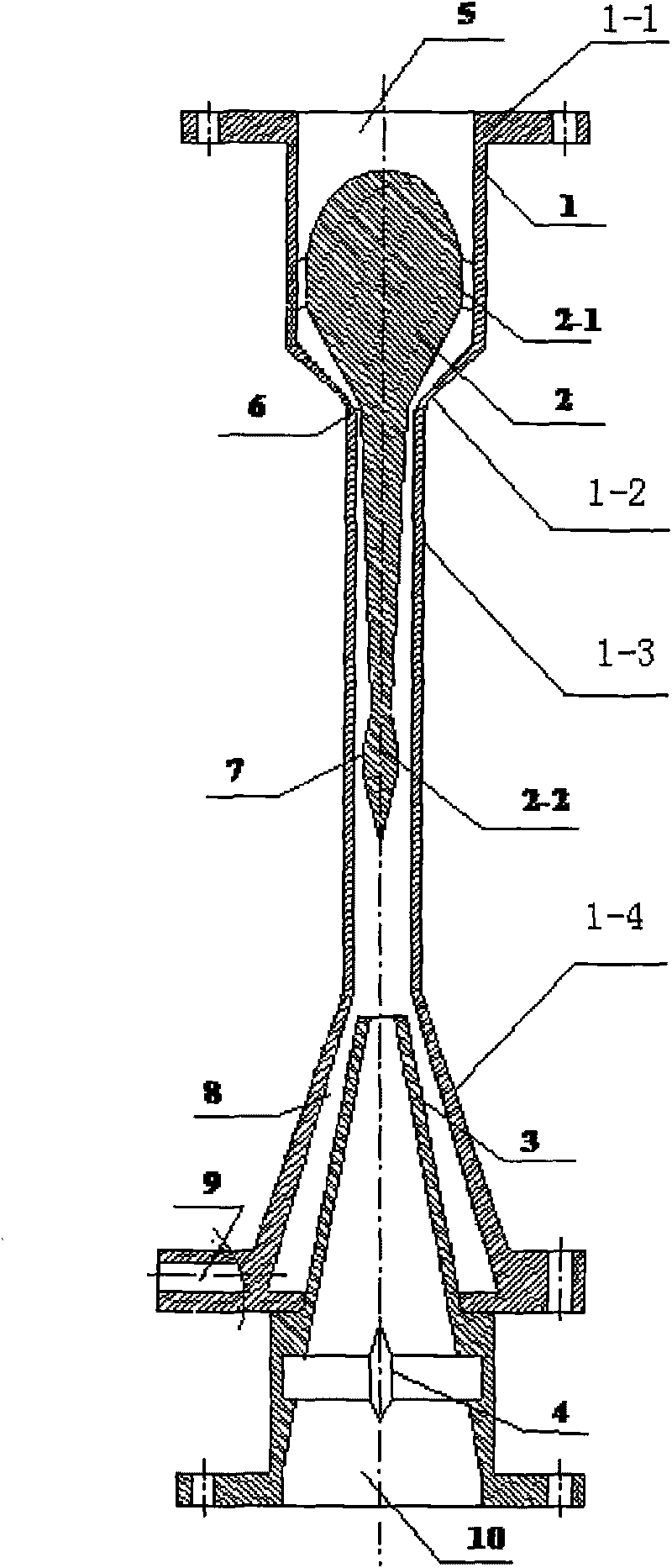

[0013] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

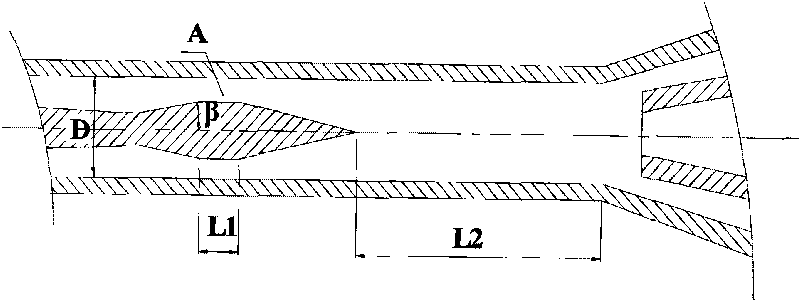

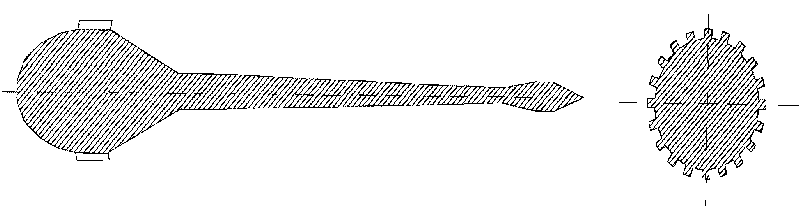

[0014] see figure 1 . -1 is provided with a central worm 2 with guide vanes 2-1, an annular channel is formed between the central worm 2 with guide vanes 2-1 and the pipeline 1, and the flow area of the annular channel shrinks first along the flow direction At throat 6, that is, the junction of tapered section 1-2 and straight section 1-3, it reaches the minimum, and its value is A t , after passing through the throat 6, it enters the equal straight section 1-3 and then expands, and finally shrinks again in the shock wave compression zone 7 at the end of the central worm 2, where the minimum flow area is A, and in the expansion section 1 of the shell 1 -4 is provided with a liquid collector 3, a liquid collecting chamber 8 is formed between the liquid collecting device 3 and the shell, and a liquid dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com