Non-master pump non-hydraulic oil type automobile clutch booster

A technology for clutches and boosters, which is applied to clutches, fluid-driven clutches, and non-mechanical drive clutches. It can solve problems such as weakened pressure in small oil chambers, powerless boosters, and lack of lubricating devices, so as to simplify the structure and increase the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

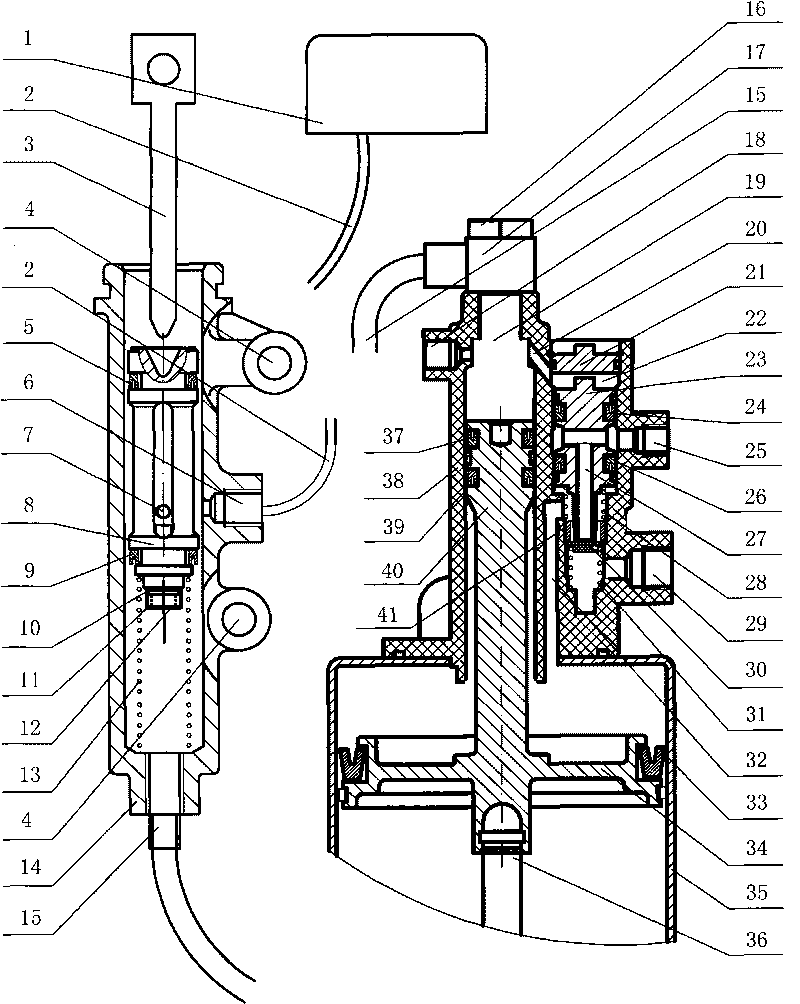

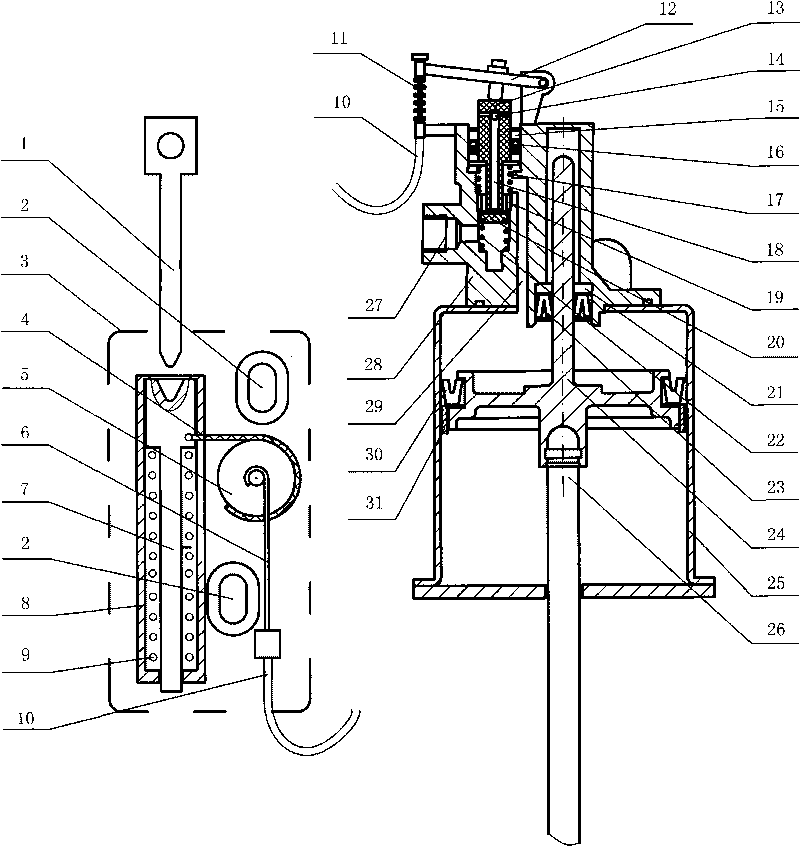

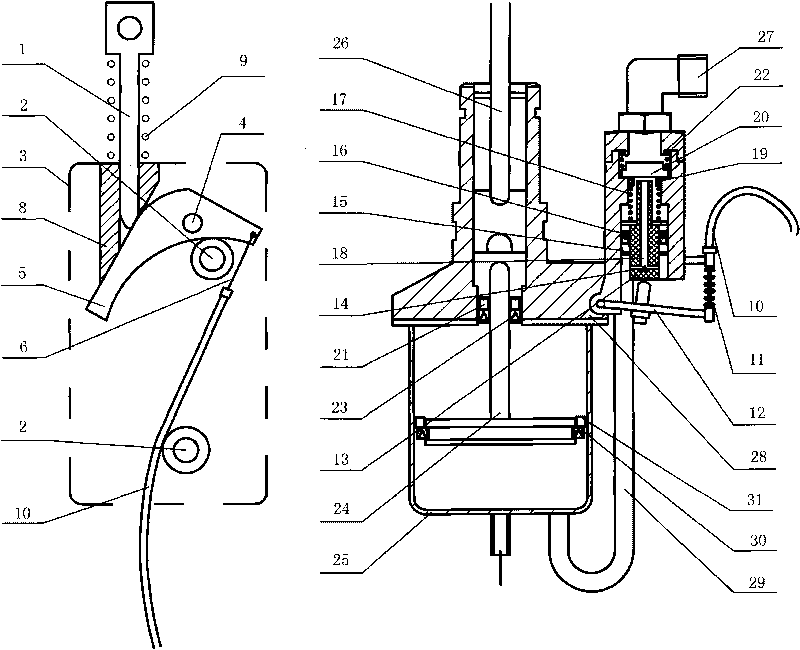

[0040] refer to figure 2 , image 3 Shown, a kind of no master cylinder no hydraulic oil type automobile clutch booster. Including master cylinder push rod 1, master cylinder installation hole 2, shell 3, soft metal pull rope 4 ( image 3 The part number 4 is the rotating shaft), the coaxial reducing wheel 5 ( image 3 Part number 5 is a special-shaped runner), the inner core of the soft stretch rod 6, the slider 7 ( image 3Part number 7 is omitted in this structure), slider slideway 8, slider return spring 9, metal software stretch rod 10, lever mechanism return spring 11, lever mechanism 12, small piston 13, exhaust adjustment valve 14 , small piston cup lubricating anti-friction ring 15, small piston cup 16, small piston return spring 17, small piston vent hole 18, valve seat 19, valve plate 20, guide column leather cup lubricating anti-friction ring 21, valve plate Return spring 22, guide column leather cup 23, large piston and guide column 24, cylinder barrel 25, ej...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com