Refractory brick inside quality online detection device

A technology for internal quality and detection devices, which is applied to program control devices, processing detection response signals, and using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., which can solve the problem of inability to perform batch detection or a large number of random inspections, and the inability to objectively judge the correctness of the detection results and Reliability, only a small amount of random inspection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

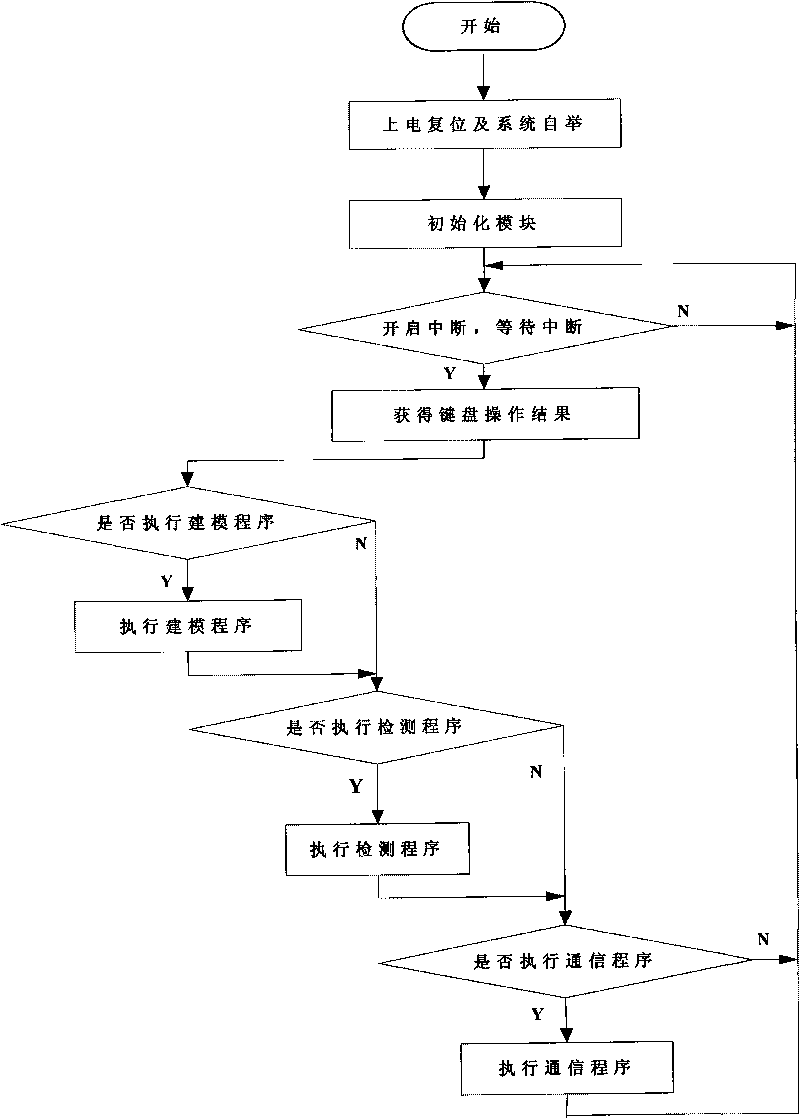

[0058] 1. The hardware and software composition of the internal quality inspection device of refractory bricks

[0059] The on-line detection device for the internal quality of refractory bricks includes two parts: hardware and software.

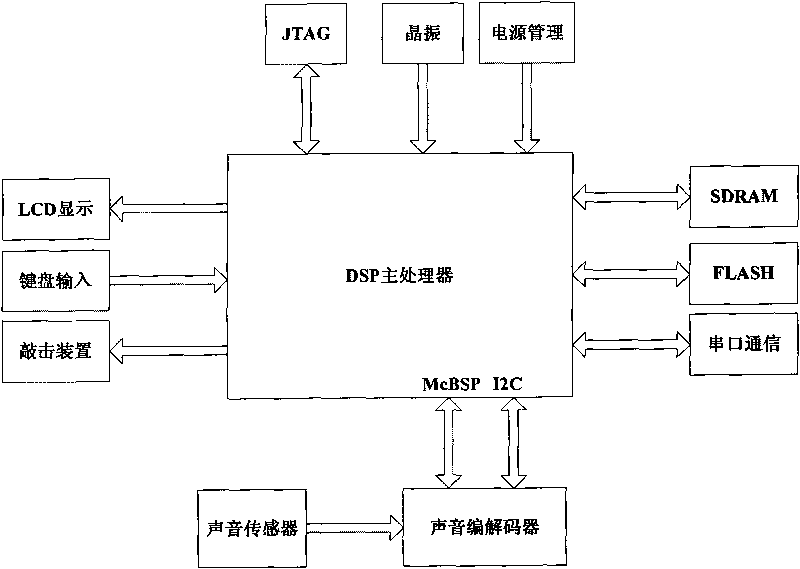

[0060] 1. The hardware system of the refractory brick internal defect detection device adopts a modular structure, including a DSP main processing module, a sound acquisition module, a PC serial communication module, an auxiliary peripheral module and a percussion module, such as figure 1 shown.

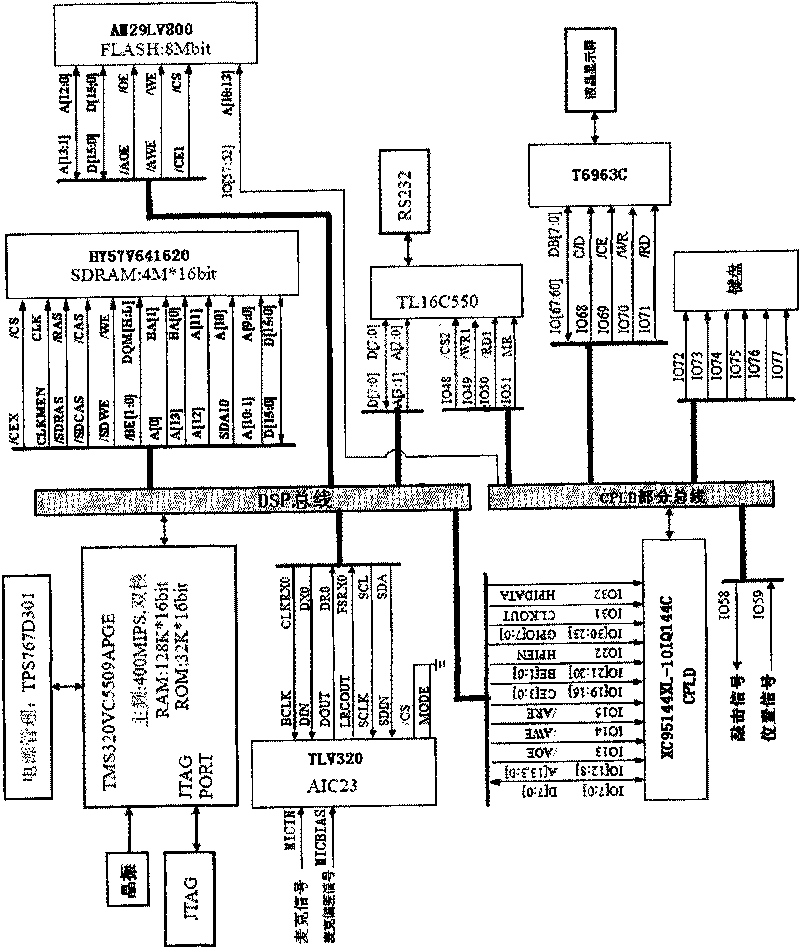

[0061] (1) DSP main processing module

[0062] The main processing chip chooses TMS320VC5509A of TI Company. Complete data processing and analysis tasks, control drivers of peripherals, and scheduling tasks of the entire system. In the main processing module, the memory should also be expanded to complete system program storage and data storage when the system is running. The 5509A manages the external storage space through the external memory ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com