Chloroethylene catalyst converted and synthesized by fluidized bed and preparation method thereof

A fluidized bed and catalyst technology, applied in the direction of hydrogen halide addition preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of no fluidized catalyst, large investment in fixed assets, low degree of automation, etc. problems, to achieve the effect of improving the technical level of automation equipment, reducing investment in fixed assets, and reducing the area occupied by equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

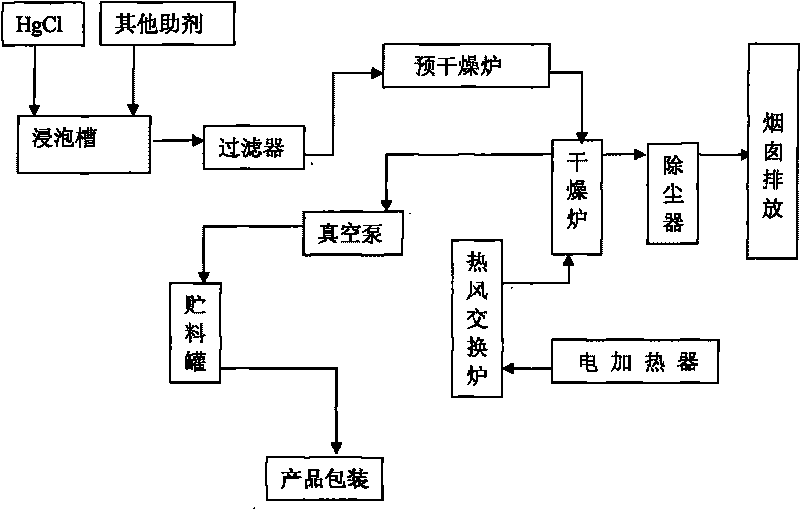

Method used

Image

Examples

Embodiment

[0043] The fluidized bed conversion synthesis vinyl chloride catalyst produced by Guiyang Baiyun Yinxing Chemical Co., Ltd., the formula of mass fraction is as follows:

[0044] Mercury Chloride 11.5%,

[0045] Rare earth chloride additive A 10%,

[0046] Alkaline earth metal chloride additive B 15%,

[0047] Auxiliary C 12%,

[0048] The remainder is activated carbon;

[0049] In the formula, the purity of the mercuric chloride is ≥99.5%; the activated carbon is special coconut shell activated carbon.

[0050] Preparation methods include:

[0051] (1) Soak activated carbon with a certain concentration of hydrochloric acid solution at 70°C and set aside;

[0052] (2) Dissolve mercuric chloride, auxiliary agent A, auxiliary agent B, and auxiliary agent C together at 70°C, and the residual solute after dissolving is ≤0.08%; 12 hours;

[0053] (3) After soaking, the intermediate product obtained is pre-dried at a low temperature below 80°C;

[0054] (4) For the pre-dried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com