Collinear preparation method for strontium hydrate and strontium carbonate

A technology of strontium hydroxide and strontium carbonate, applied in the direction of calcium carbonate/strontium/barium, calcium/strontium/barium oxide/hydroxide, etc., can solve the problems of difficulty in recycling, environmental pollution, and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

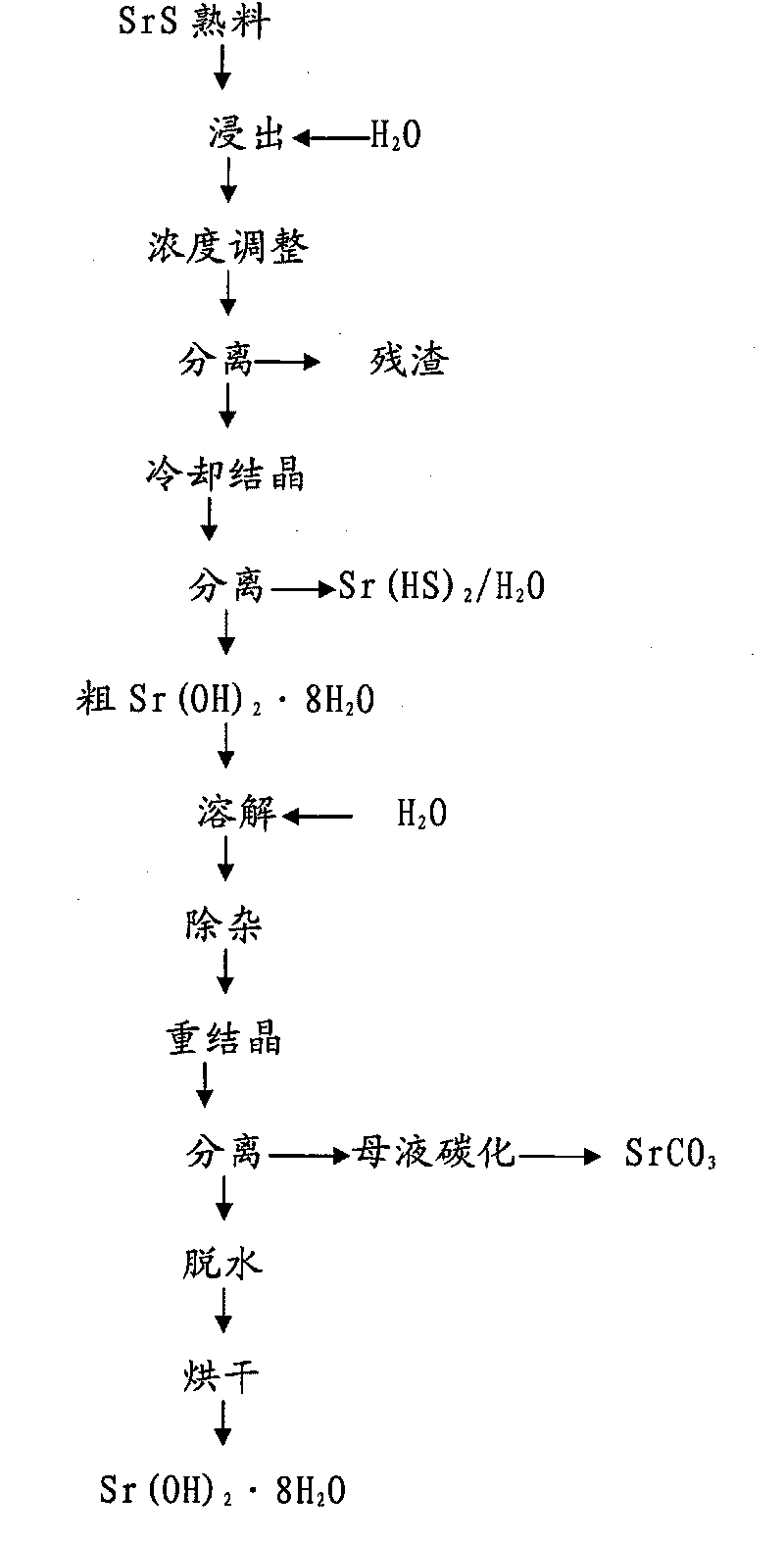

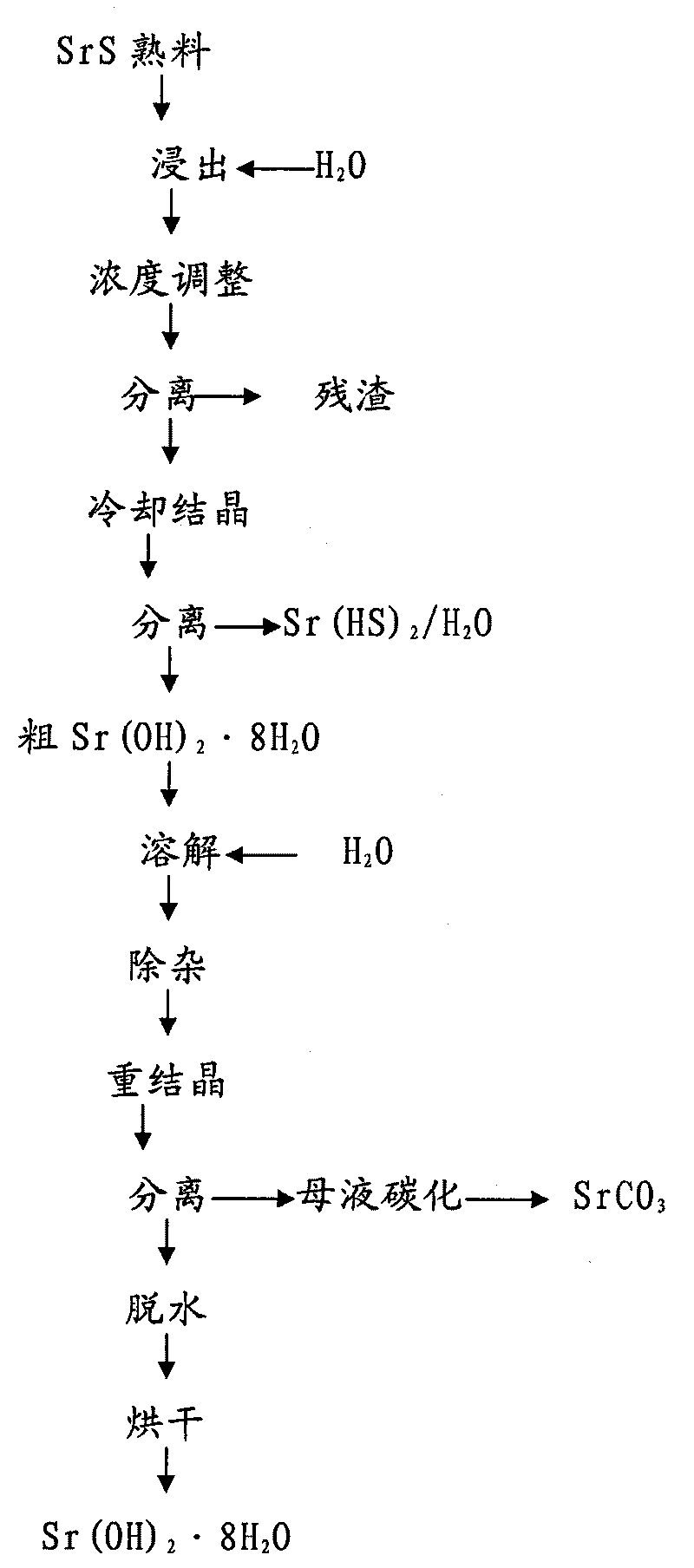

Method used

Image

Examples

Embodiment 1

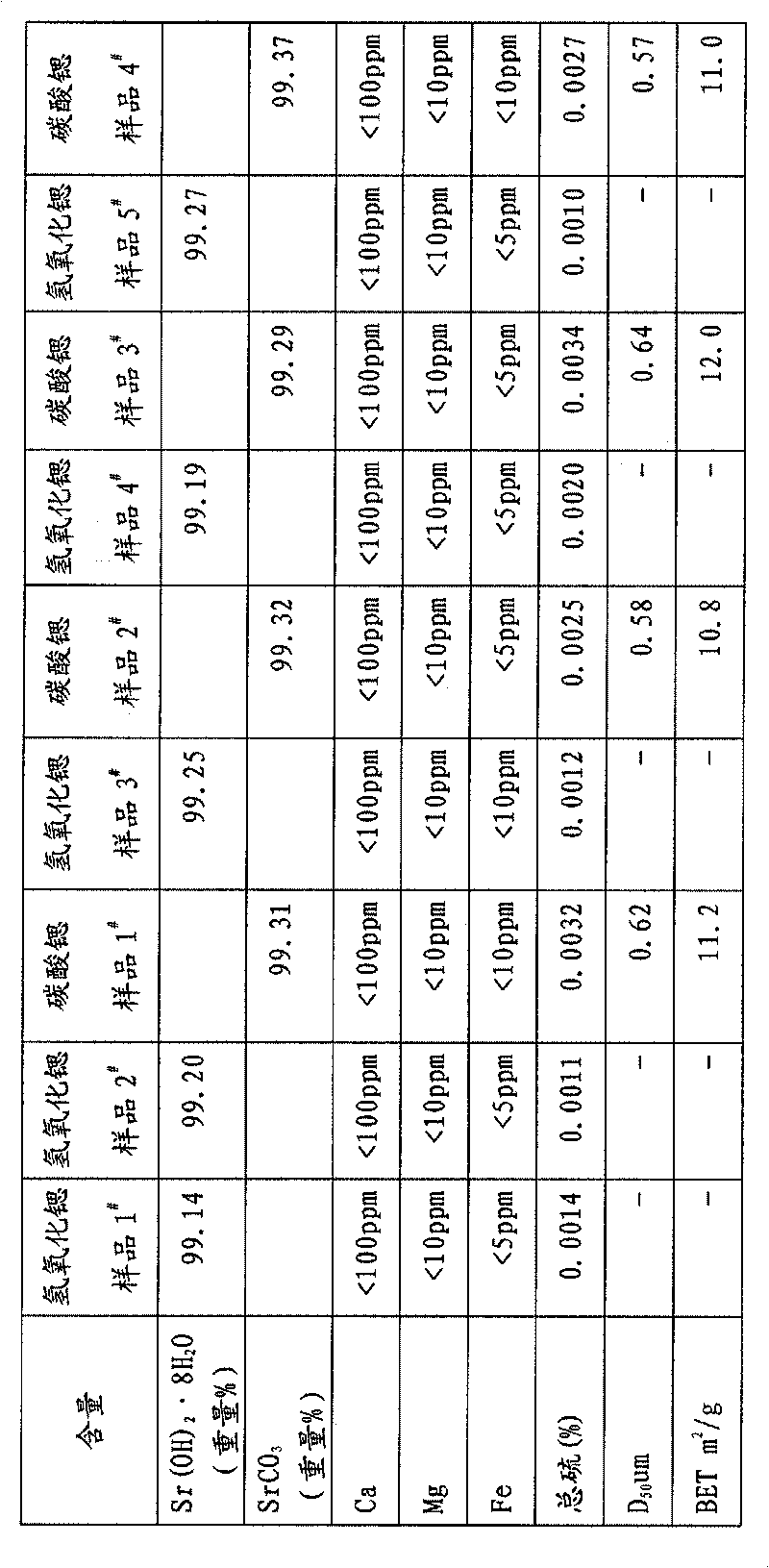

[0012] Take 1kg of 37% by weight SrS clinker, put it in a 5000ml beaker, add 4000ml of deionized water, stir in an airtight furnace and heat to 85°C in an electric furnace, control the SrS concentration to 110g / L, and leaching for 2 hours. Then use a latex tube to siphon the supernatant into a clean 5000ml beaker, seal the beaker with a plastic bag, put it in cooling water and cool it to 35°C, take it out, and carry out suction filtration and separation. 2 Carbonization to produce common SrCO 3 .

[0013] The crude Sr(OH) after suction filtration 2 ·8H 2 O according to 0.8mol / L [Sr 2+ ] was dissolved in deionized water, and 27.5% by weight of H was added in a ratio of 1.5ml / L 2 o 2 , airtightly heat up and stir, keep boiling slightly for 20 minutes, stop heating, filter with slow qualitative filter paper, discard the filter residue, airtightly cool the filtrate to 40°C and then centrifuge for dehydration, the mother liquor is dehydrated with CO 2 Preparation of low-sulfu...

Embodiment 2

[0015] Take 2kg of 42% by weight SrS clinker, put it in a 5000ml beaker, add 4000ml of deionized water, keep warm and leaching in a boiling water bath at 100°C for 3 hours, the actual leaching temperature is 95°C, and control the SrS concentration to 100g / L, during which every Stir once every 30 minutes, after static settling, absorb the supernatant by siphon method, then add 4000ml deionized water, soak for 3 hours in a boiling water bath at 100°C, combine the second clear liquid and put it in a 10L plastic bucket and cool it down to 45°C Separation by suction filtration, carbonization of mother liquor to prepare ordinary SrCO 3 .

[0016] The crude Sr(OH) separated by suction filtration 2 ·8H 2 O according to 0.7mol / L [Sr 2+ ] Dissolved by heating with deionized water, adding 27.5% by weight of H at a ratio of 1.3ml / L 2 o 2 , electric furnace heating, airtight heating and stirring, after boiling, maintain a slight boiling for 25 minutes, stop heating, filter with slow q...

Embodiment 3

[0018] Take 2kg of 42% by weight SrS clinker, put it in a 5000ml beaker, add 4000ml of deionized water, stir in an airtight furnace and heat to 95°C in an electric furnace, control the SrS concentration to 100g / L, and leaching for 3 hours. After static settling, use the siphon method to absorb the supernatant, then add 4000ml of deionized water, and then leaching for 3 hours, combine the secondary supernatant and put it in a 10L plastic bucket, airtightly cool it to 30°C, and then separate it by suction filtration, carbonize the mother liquor to prepare ordinary SrCO 3 .

[0019] The crude Sr(OH) separated by suction filtration 2 ·8H 2 O according to 0.7mol / L [Sr 2+ ] Dissolved by heating with deionized water, adding 27.5% by weight of H at a ratio of 1.3ml / L 2 o 2 , electric furnace heating, airtight heating and stirring, after boiling, maintain a slight boiling for 25 minutes, stop heating, filter with slow qualitative filter paper, discard the filter residue, seal the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com