Insulation rubber for cable

A rubber and cable technology, used in rubber insulators, organic insulators, etc., can solve the problems of production and use constraints, high production costs, reduce raw material costs, outstanding electrical insulation performance and ozone resistance, and good chemical stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

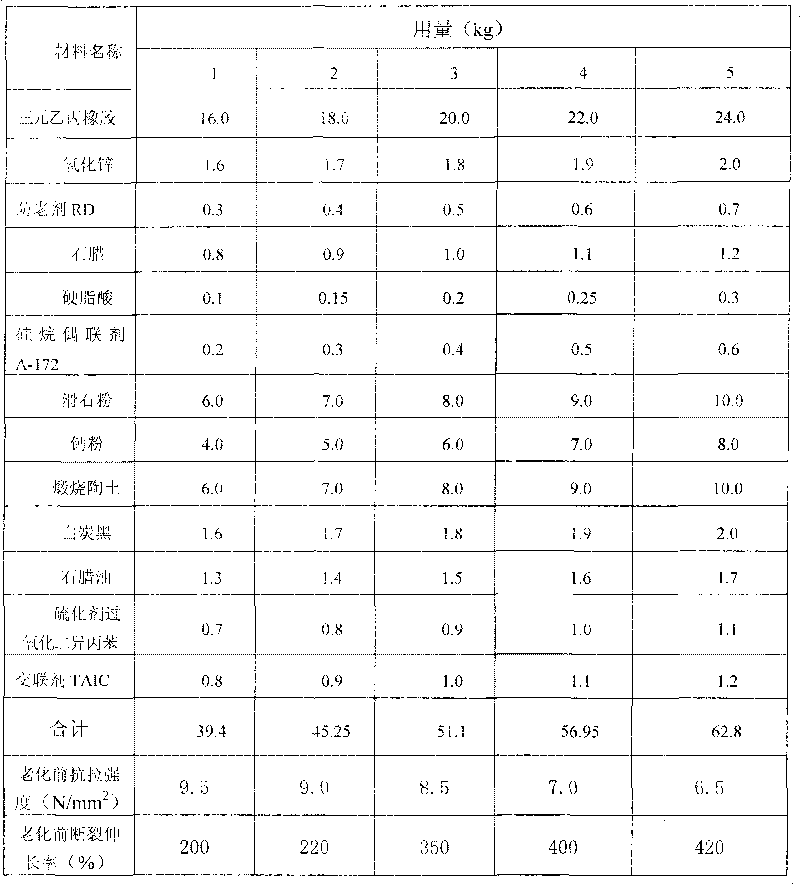

Method used

Image

Examples

Embodiment Construction

[0007] In the process of implementing the present invention, we have scientifically demonstrated the performance and technical indicators of the main ingredients of the formula and related compounding agents, especially through our many tests, the results show that the use of the present invention can improve product quality. , It can also reduce product cost and improve product performance, so as to achieve higher economic and social benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com