Reduction furnace for smelting metal magnesium

A reduction furnace and metal magnesium technology, applied in the field of reduction furnaces, can solve the problems of instability, uneven temperature field of the reduction furnace, unreasonable flame structure, etc., and achieve the effects of enhanced heat exchange effect, uniform furnace temperature and unique combustion mode.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

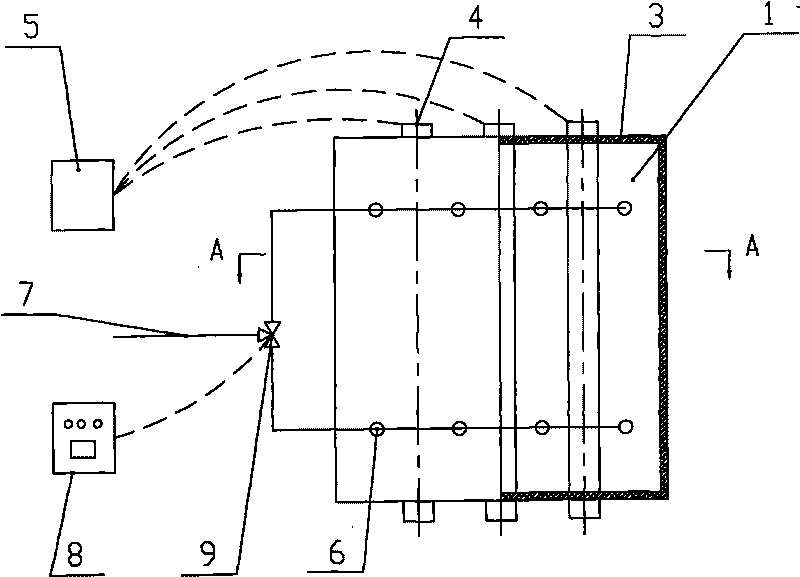

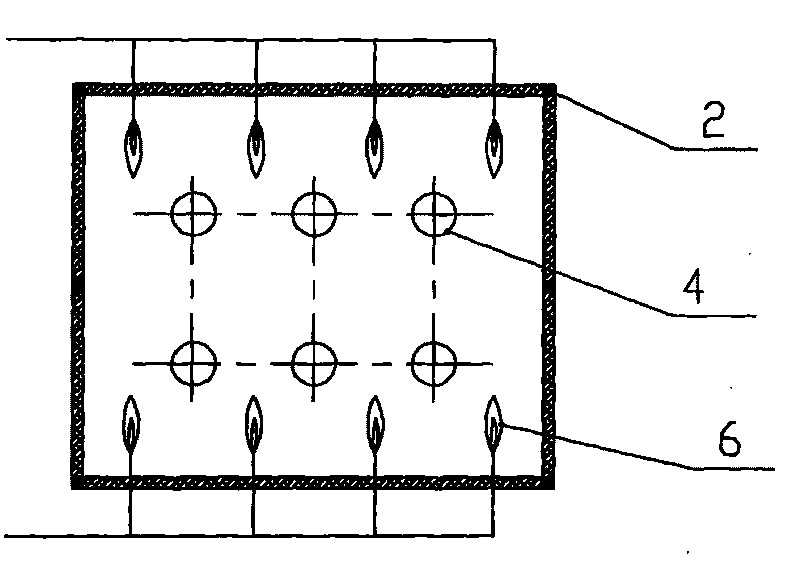

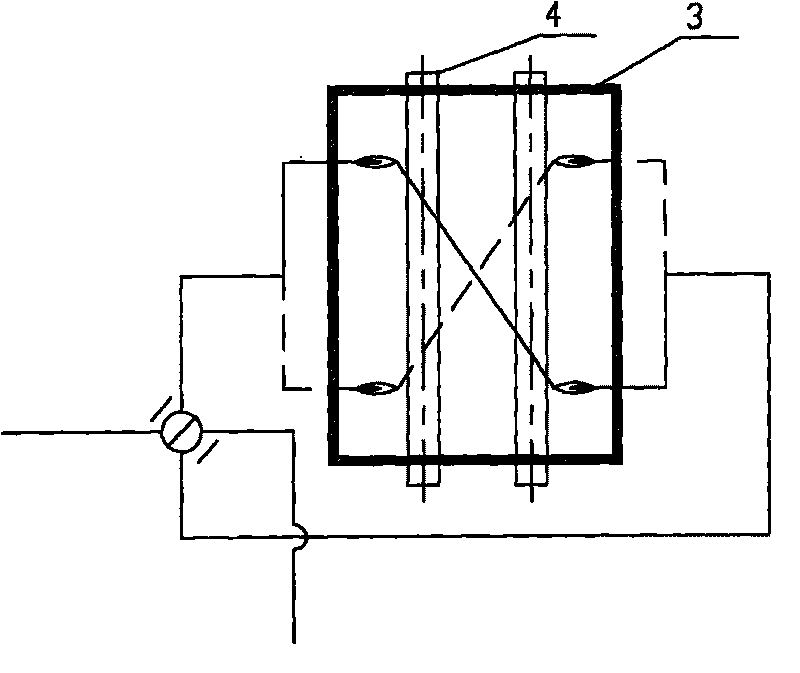

[0022] A metal magnesium smelting reduction furnace, comprising a furnace body 1, a steel frame 2 supporting the furnace body 1, a furnace wall 3, a reduction tank 4 installed on the furnace body 1, a vacuum system 5 connected to the reduction tank 4, and a furnace body 1 Combustion and flue gas systems 7 are provided on both sides, such as figure 1 and 2 As shown: the furnace walls 3 on both sides of the reduction furnace body 1 are provided with at least two layers of burners 6 that can be used as smoke outlets. The nozzles of the burners 6 face the hearth of the reduction furnace. The burners 6 up and down are staggered left and right, and the burners 6 on the furnace walls 3 on both sides correspond up and down. The burners 6 are all connected with a control system 8, and each burner 6 is equipped with a replacement Reversing valve 9, reversing valve 9 is connected with above-mentioned control system 8.

[0023] The above-mentioned reduction furnace body 1 is of a heat s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com