Gas nozzle with double gas source

A gas nozzle and dual gas source technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of difficult manufacturing and high noise, and achieve the effects of reducing manufacturing accuracy, eliminating noise, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

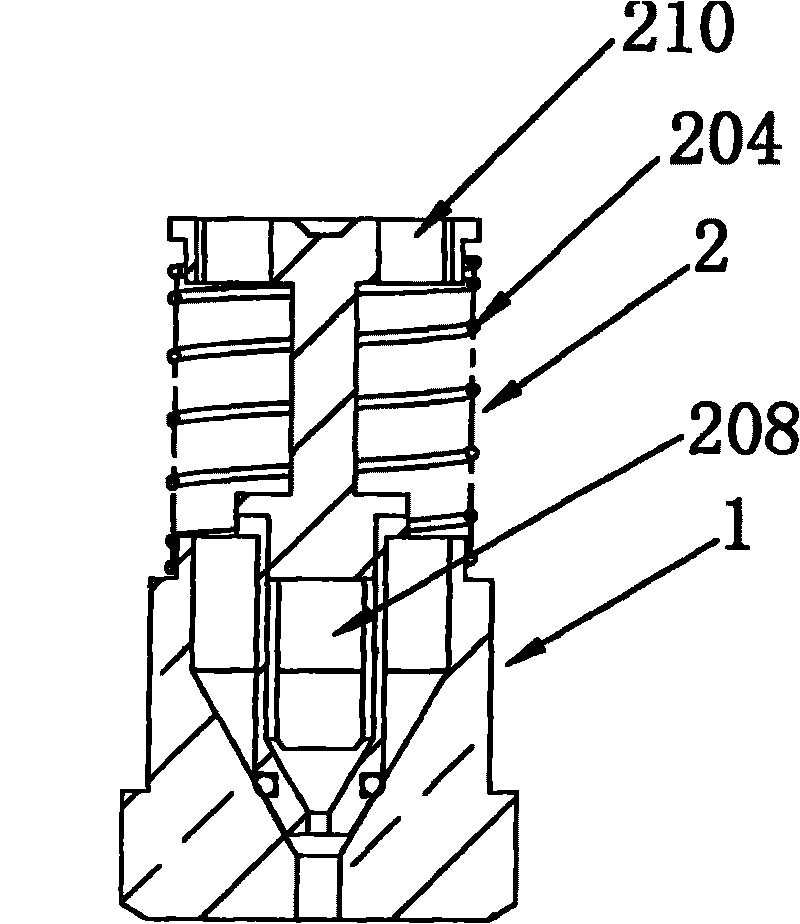

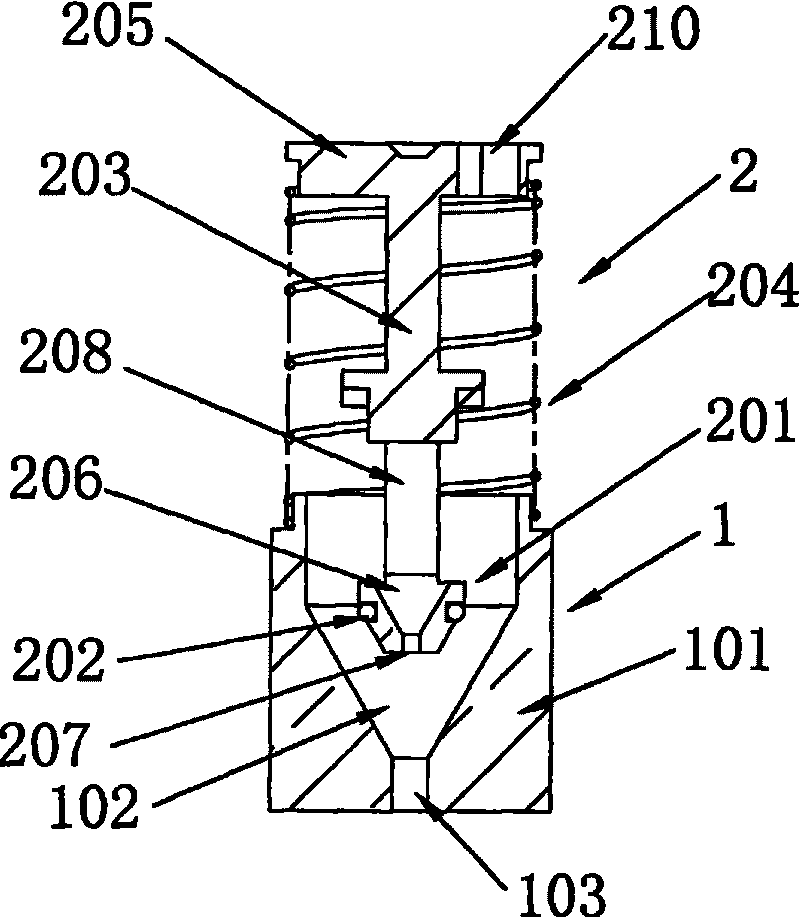

[0021] Such as figure 1 , 2 shown.

[0022] A dual gas source gas nozzle, comprising an outer nozzle 1 and an inner nozzle 2, the nozzle body 101 of the outer nozzle 1 is provided with an air cavity 102 and an injection hole 103 communicating with the air cavity 102, and the diameter of the injection hole 103 depends on The flow rate requirements of a specific type of gas appliance for a low calorific value gas source; the surface of the nozzle body 101 is provided with a connecting thread connected with the spool of the selector valve, and the air cavity 102 can be a frustum-shaped cavity, or a figure 1 Or as shown in 2, a compound cavity composed of a cylindrical shape and a truncated cone shape, the inner nozzle 2 is composed of an inner nozzle body 201, a sealing ring 202, a connecting rod 203 and a return spring 204, and the inner nozzle body 201 is located at the outer nozzle 1 The air chamber 102 of the inner nozzle 102 is connected with one end of the connecting rod ...

Embodiment 2

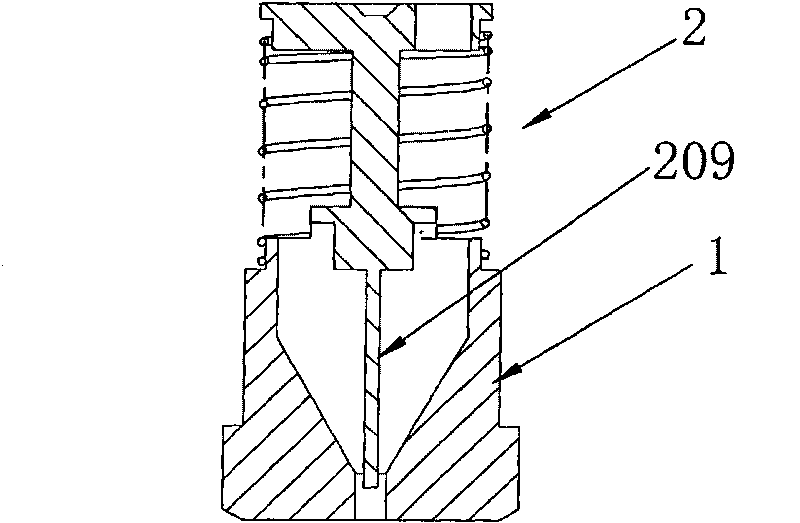

[0026] Such as image 3 , 4 shown.

[0027] A dual gas source gas nozzle, comprising an outer nozzle 1 and an inner nozzle 2, the nozzle body 101 of the outer nozzle 1 is provided with an air chamber 102 and a spray hole 103 communicating with the air chamber 102, the inner nozzle 2 It is composed of a valve rod 209, a connecting rod 203 and a return spring 204. One end of the valve rod 209 is connected to the connecting rod 203, and the other end of the valve rod 209 is movably inserted into the spray hole 104. The diameter of the spray hole 103 depends on the specific type of gas The diameter of the valve rod 209 depends on the flow requirements of a specific type of gas appliance for the high calorific value gas source. One end of the return spring 204 is in contact with the nozzle body 101, and the other end is in contact with the inlet on the connecting rod 203. Gas disc 205 offsets.

[0028] When the gas used was a high calorific value, the valve body in the inner noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com