Method for detecting inclusions and air holes in aluminum alloy

A technology for aluminum alloys and inclusions, which is applied in the preparation of test samples, material resistance, etc., can solve the problems of low detection accuracy of inclusions and pores, and achieve the effect of simple and convenient implementation and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

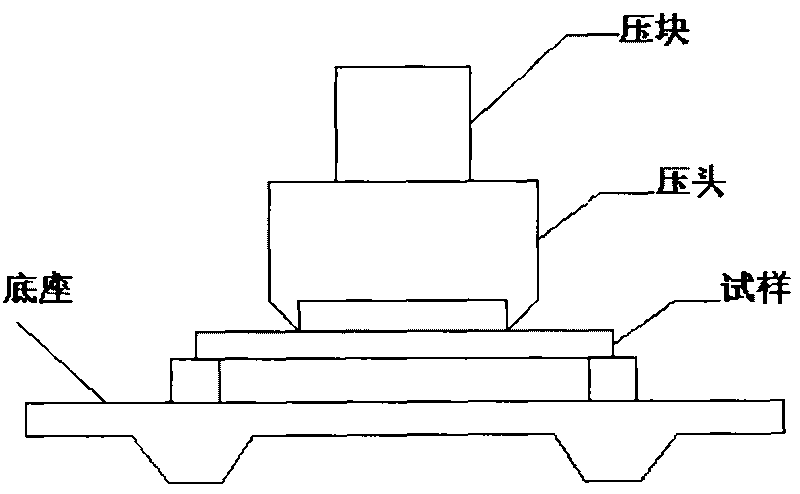

Image

Examples

Embodiment 1

[0024] The technological process and steps of the present embodiment are as follows:

[0025] a Sample preparation: The experimental material is ADC12 aluminum alloy, and the melting temperature is 790 °C. The molten aluminum is purified by flux method. After adding flux, cast 3 samples, namely No. 1, No. 2 and No. 3. Two samples were poured before adding flux, namely No. 4 and No. 5. These five samples were made into strips with a size of 2mm×5mm×60mm.

[0026] b Coarse grinding-fine grinding: Grind the prepared sample on 200#, 400#, 600#, 800# sandpaper until there is no scratch on the surface of the sample, and keep the flatness of the sample as much as possible.

[0027] c measurement: due to the wear of the sample during the grinding process, the size should be measured again. Measure the width and height of the sample with a vernier caliper, and record it in Table 1:

[0028] Table 1 The cross-sectional length and width of the sample

[0029] Sample No

...

Embodiment 2

[0039] The technological process and steps of the present embodiment are as follows:

[0040] a Sample preparation: The experimental material is ADC12 aluminum alloy, and the melting temperature is 790 °C. The molten aluminum was purified by the flux method, and a sample was poured before and after purification. These two samples were made into strips with a specification of 2mm×5mm×60mm.

[0041] b Coarse grinding-fine grinding: Grind the prepared sample on 200#, 400#, 600#, 800# sandpaper until there is no scratch on the surface of the sample, and keep the flatness of the sample as much as possible.

[0042] c measurement: due to the wear of the sample during the grinding process, the size should be measured again. Measure the width and height of the sample with a vernier caliper, and calculate the actual cross-sectional area of the sample.

[0043] d Measure the resistivity of the sample with an alloy resistivity measuring device. The prepared samples were heated in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com