Structure and method for enhancing adhesive strength of a panel sealant

A technology of adhesion strength and sealant, applied in nonlinear optics, instruments, optics, etc., can solve the problems of inability to achieve support, affecting adhesion strength and panel gaps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

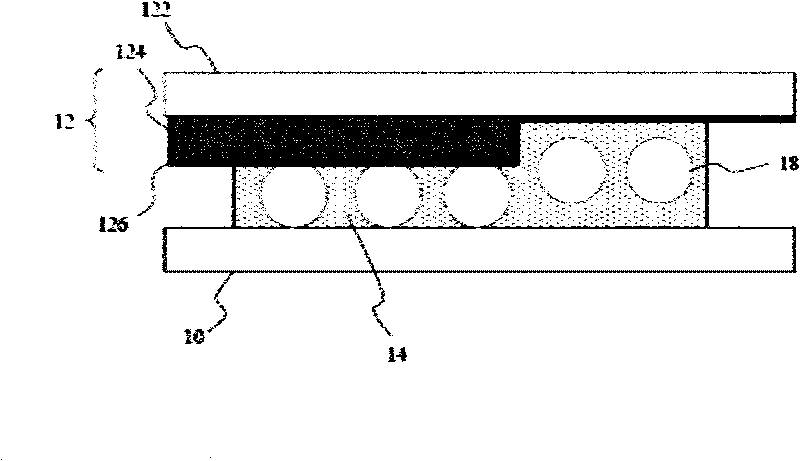

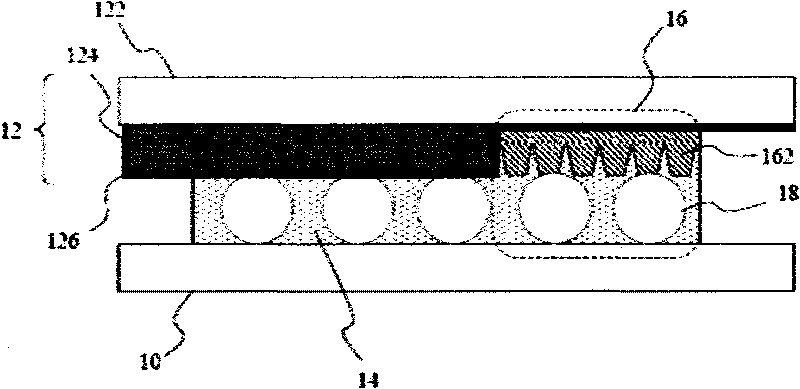

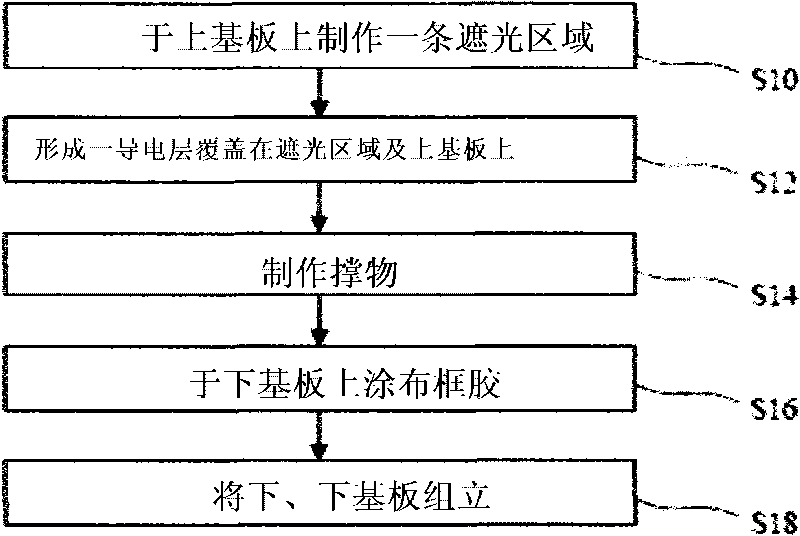

[0016] The invention provides a structure and method for increasing the adhesive strength of panel frame glue, figure 2 Shown is the structure of the present invention, comprising a lower substrate 10, an upper substrate 12 and a support area 16, an upper substrate 12, a color filter substrate 122, a light-shielding area 124 and a conductive layer 126, wherein the light-shielding area 124 is in the color On the filter substrate 122, the conductive layer 126 is formed outside the color filter substrate 122 and the light-shielding area 124; the light-shielding area 124 is a black matrix (Black Matrix), and the conductive layer 126 is an indium tin oxide layer (ITO); The lower substrate 10 is provided with a sealant 14 for adhering the upper substrate 12 and the lower substrate 10; the support area 16 includes a plurality of supports 162 and at least one spacer 18, wherein the support 162 is made of a gray tone film (GrayTone Mask ) or half-tone film (Half Tone Mask) mask method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com